Application of surface tension adjustment reduction type polycarboxylate superplasticizer in preparing high-performance concrete

A technology of high-performance concrete and surface tension, applied in the field of water reducing agent, can solve problems such as low water-binder ratio, large increase in project cost, and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

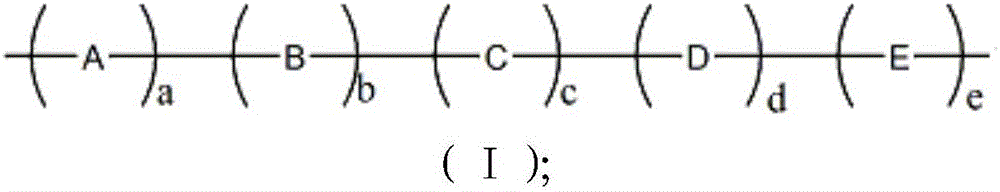

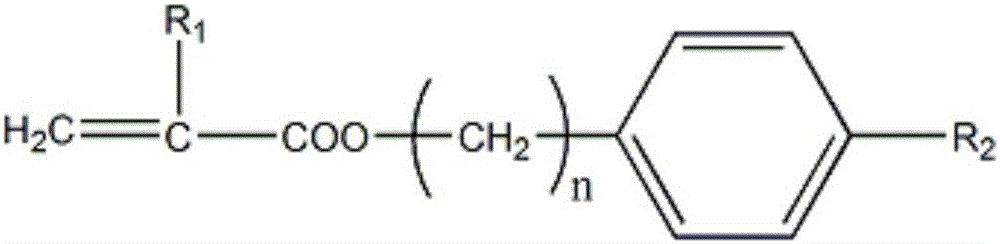

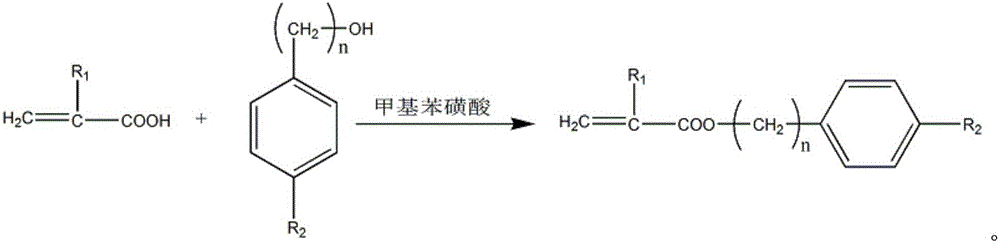

[0086] An embodiment of the surface tension-adjusted shrinkage-reduced polycarboxylic acid water reducer of the present invention, the preparation method of the surface tension-adjusted shrinkage-reduced polycarboxylic acid water reducer is as follows:

[0087] (1) In a 500ml four-necked glass flask equipped with a stirrer, thermometer and reflux condenser, add 0.5mol methacrylic acid, 0.5mol benzyl alcohol, and methylbenzenesulfonic acid (the amount is methacrylic acid and benzyl alcohol). 2% of the total weight), 4-methoxyphenol (the amount is 0.2% of the total weight of methacrylic acid and benzyl alcohol), stir, heat up to 80°C, keep for 6 hours, and cool down to obtain the reaction product benzyl methacrylate Base ester.

[0088] (2) Add 1200ml of water, methacrylic acid, APEG, allyl polyoxypropylene ether, sodium allyl benzene sulfonate, mercaptoethanol, 2000ml four-necked glass flask equipped with a stirrer, thermometer and reflux condenser. In the benzyl methacrylate obtai...

Embodiment 2

[0090] An embodiment of the surface tension-adjusted shrinkage-reduced polycarboxylic acid water reducer of the present invention, the preparation method of the surface tension-adjusted shrinkage-reduced polycarboxylic acid water reducer is as follows:

[0091] (1) In a 500ml four-neck glass flask equipped with a stirrer, a thermometer and a reflux condenser, add 0.6 mol of acrylic acid, 0.5 mol of methyl benzyl alcohol, and methyl benzene sulfonic acid (the amount is methacrylic acid and benzyl alcohol). 2.5% of the total weight), methoxyhydroquinone (the amount is 0.3% of the total weight of methacrylic acid and benzyl alcohol), stir, heat up to 90°C, keep the temperature for 5 hours, and cool down to obtain the reaction product methyl benzyl acrylate ester.

[0092] (2) Add 1200 ml of water, acrylic acid, HPEG, allyl polyoxypropylene ether, sodium allyl benzene sulfonate, thioglycolic acid, step (2) into a 2000 ml four-neck glass flask equipped with a stirrer, thermometer and re...

Embodiment 3

[0094] An embodiment of the surface tension-adjusted shrinkage-reduced polycarboxylic acid water reducer of the present invention, the preparation method of the surface tension-adjusted shrinkage-reduced polycarboxylic acid water reducer is as follows:

[0095] (1) In a 500ml four-neck glass flask equipped with a stirrer, a thermometer and a reflux condenser, add 0.6 mol of methacrylic acid, 0.5 mol of phenethyl alcohol, and methylbenzene sulfonic acid (the amount is the total amount of methacrylic acid and benzyl alcohol). 2% by weight), 4-methoxyphenol (the amount is 0.2% of the total weight of methacrylic acid and benzyl alcohol), stir, heat up to 85°C, keep the temperature for 6h, and cool down to obtain the reaction product styrene ethyl methacrylate ester.

[0096] (2) Add 1200ml water, methacrylic acid, VPEG, allyl polyoxypropylene ether, sodium allyl benzene sulfonate, mercaptopropanol into a 2000ml four-neck glass flask equipped with a stirrer, thermometer and reflux conde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com