Easily-molded polypropylene foaming bead and preparation method thereof

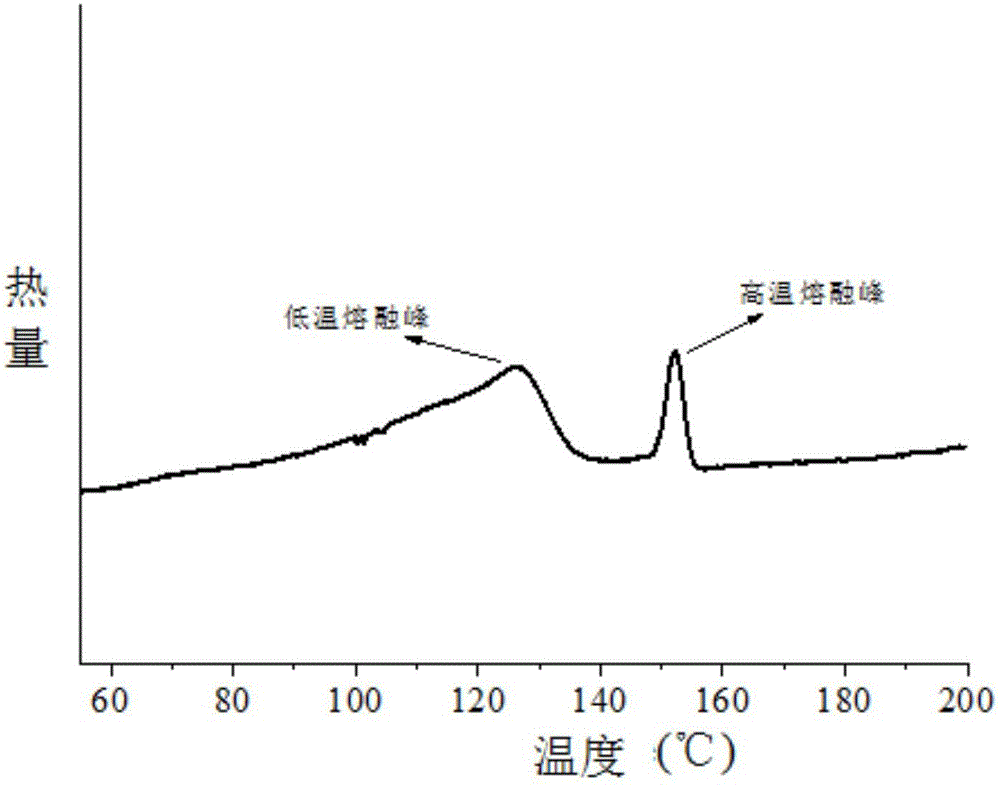

A technology of foaming beads and molding, which is applied in the field of polypropylene foaming beads, can solve the problems of high steam pressure of EPP beads and hinder the mutual fusion of foamed particles, so as to achieve good fusion and save energy consumption , The effect of less inorganic barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] An easily moldable polypropylene foam bead comprising the following components:

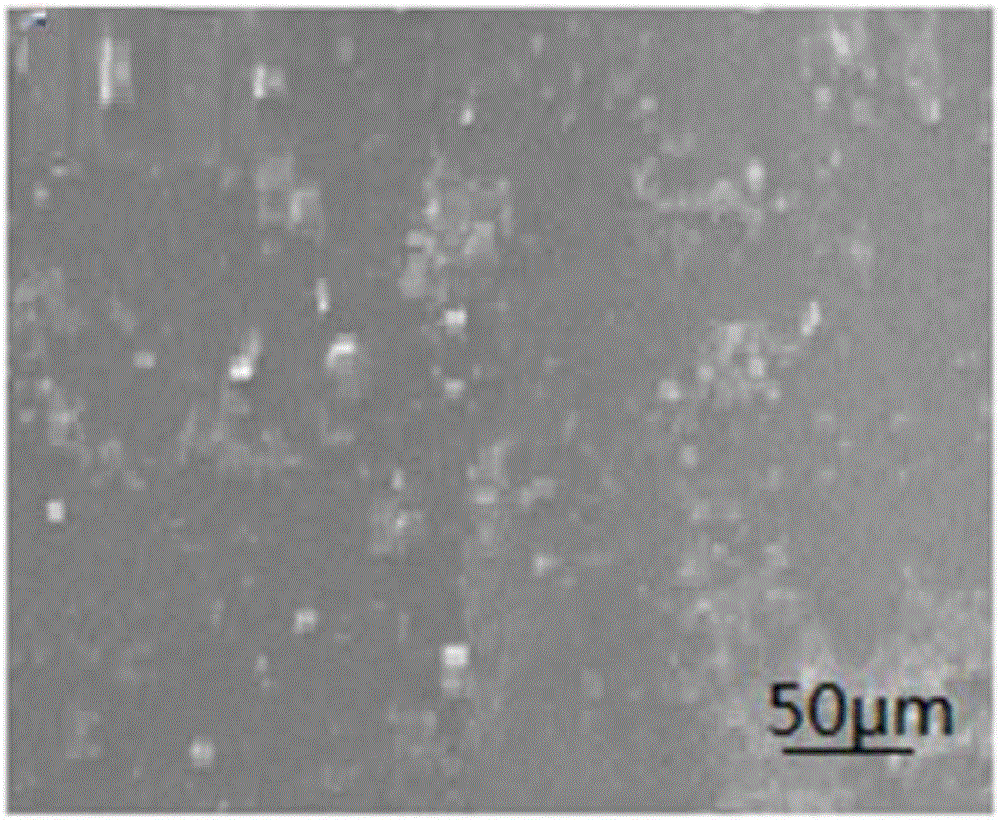

[0020] Dispersant, the dispersant particle size is the kaolin of hydrated aluminosilicate of 20 μm, consumption is 3kg;

[0021] Propylene-ethylene-butene random copolymer resin 500kg, propylene mole fraction ≥ 80%;

[0022] Aqueous dispersion medium deionized water 1000kg;

[0023] Physical blowing agent CO 2 .

Embodiment 2

[0025] An easily moldable polypropylene foam bead comprising the following components:

[0026] Dispersant, the dispersant particle size is the kaolin of hydrated aluminosilicate of 20 μm, consumption is 2kg;

[0027] Propylene-ethylene-butene random copolymer resin 500kg, propylene mole fraction ≥ 80%;

[0028] Aqueous dispersion medium deionized water 1000kg;

[0029] Physical blowing agent CO 2 .

Embodiment 3

[0031] An easily moldable polypropylene foam bead comprising the following components:

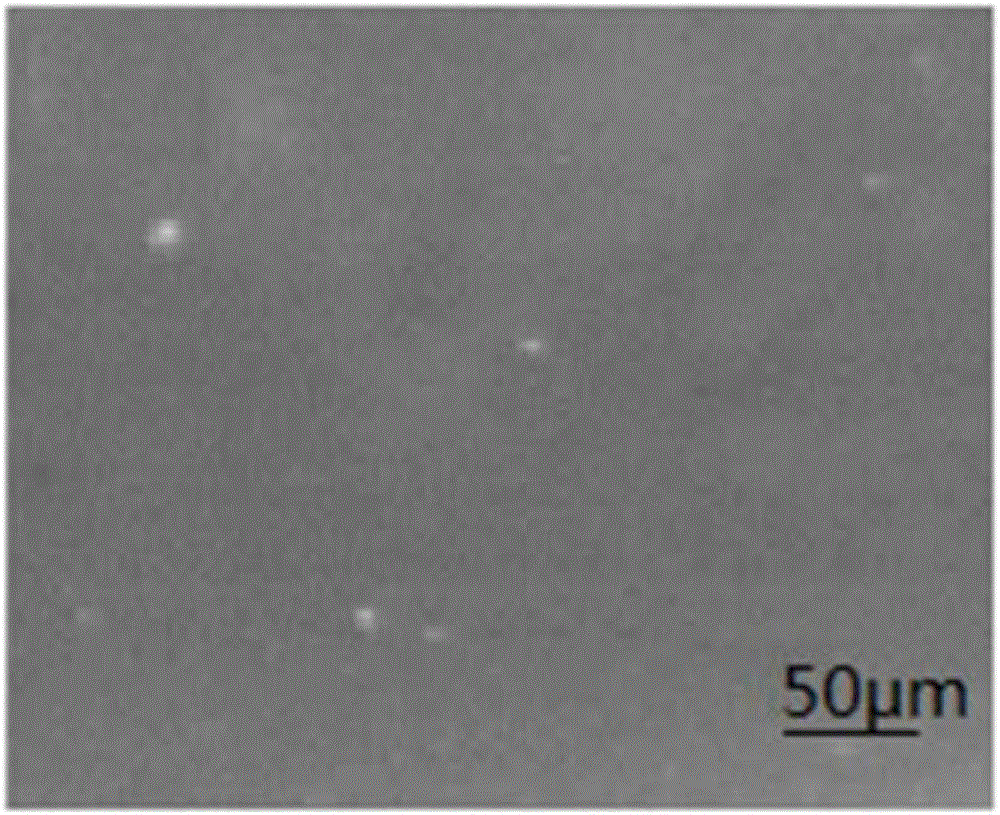

[0032] Dispersant, the dispersant particle size is the kaolin of hydrated aluminosilicate of 2 μm, consumption is 3kg;

[0033] Propylene-ethylene-butene random copolymer resin 500kg, propylene mole fraction ≥ 80%;

[0034] Aqueous dispersion medium deionized water 1000kg;

[0035] Physical blowing agent CO 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com