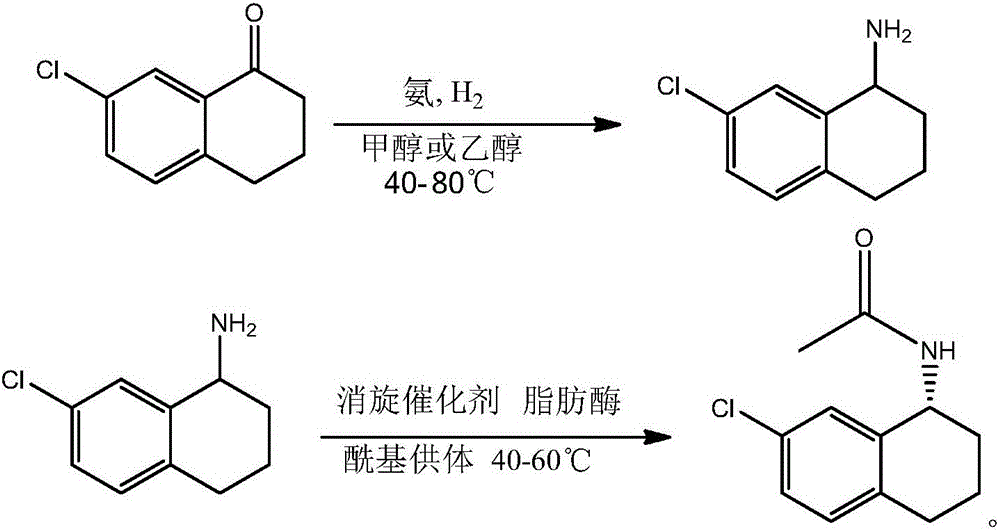

Preparation method of R-7-chloro-1-tetralinylamine

A technology of tetralamine and R-7-, which is applied in the field of synthesis and resolution of chiral amines, to achieve the effects of good product yield, great guidance and application value, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0006] 1) Preparation of 7-chloro-1,2,3,4-tetrahydronaphthalene-1-amine

[0007] In a 1000ml autoclave, add 90g 7-chloro-1-tetralone, 600ml anhydrous ethanol, 12g catalyst SN-600P, seal the reaction kettle, use a vacuum pump to remove the air in the kettle, and then fill with nitrogen to 0.5MPa, and then use The vacuum pump is used for vacuuming; 80g ammonia gas is charged under negative pressure. After the ammonia gas is filled, the autoclave is charged with hydrogen gas to 4MPa and heated to 90°C for reaction. After 9 hours of reaction, it was found that the hydrogen pressure did not drop anymore, and the reaction was stopped. After the temperature of the system drops to room temperature, the reaction solution is filtered and concentrated to obtain crude 7-chloro-1,2,3,4-tetrahydronaphthalene-1-amine. Add the crude product to the dilute hydrochloric acid solution with stirring, let it react to form 7-chloro-1,2,3,4-tetrahydronaphthalene-1-amine salt, and dissolve it in the aqu...

Embodiment 2

[0013] 1) Preparation of 7-chloro-1,2,3,4-tetrahydronaphthalene-1-amine

[0014] In a 1000ml autoclave, add 90g 7-chloro-1-tetralone, 600ml anhydrous ethanol and 10g catalyst SN-600P, seal the reaction kettle, use a vacuum pump to remove the air in the kettle, then fill with nitrogen to 0.5MPa, and then use The vacuum pump is used for vacuuming; under negative pressure, 51g of ammonia is filled. After the ammonia is filled, the autoclave is filled with hydrogen to 4MPa, and the temperature is raised to 80°C for reaction. After reacting for 10 hours, it was found that the hydrogen pressure no longer dropped, and the reaction was stopped. After the temperature of the system drops to room temperature, the reaction solution is filtered and concentrated to obtain crude 7-chloro-1,2,3,4-tetrahydronaphthalene-1-amine. Add the crude product to the dilute hydrochloric acid solution with stirring, let it react to form 7-chloro-1,2,3,4-tetrahydronaphthalene-1-amine salt, and dissolve it in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com