On-line spray type quenching equipment for steel tubes

A quenching equipment and spray technology, applied in the field of steel rolling, can solve the problems of difficulty in ensuring water supply flow, pressure stability, reducing the service life of water system equipment, unqualified steel pipe quenching quality, etc. The effect of saving construction investment costs, reducing production and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

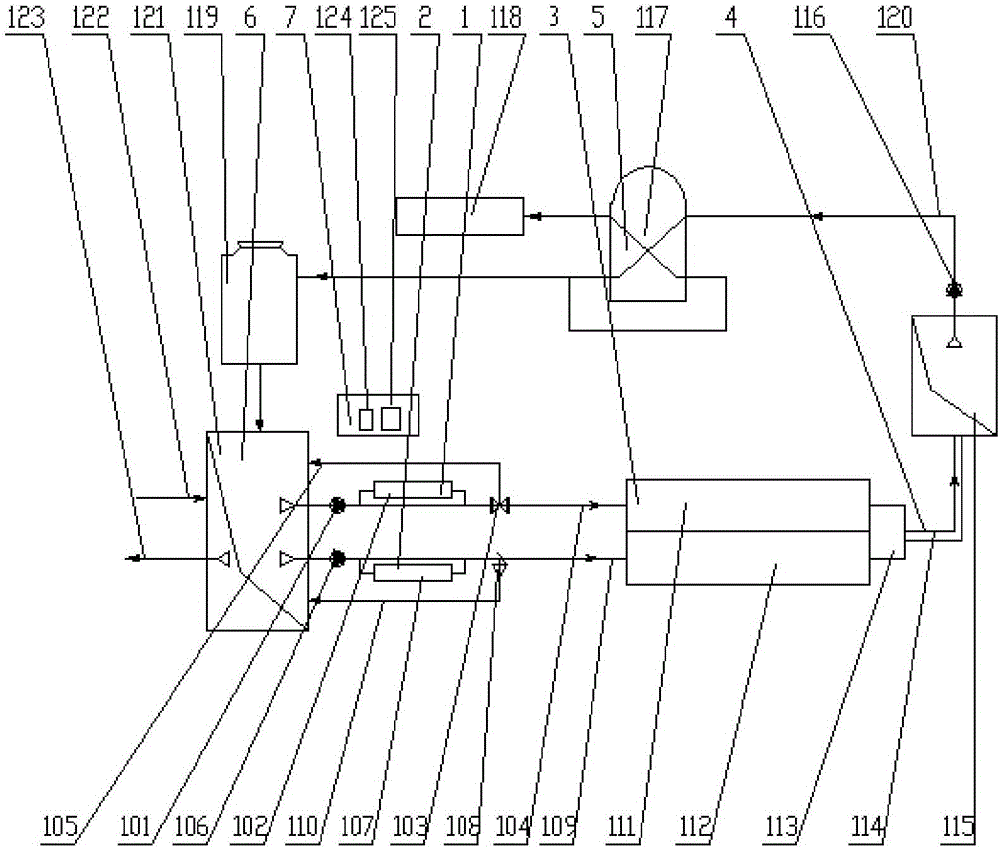

[0084] Such as figure 1 As shown, this embodiment provides an online spray quenching equipment suitable for steel pipes, which is an independent water system in terms of water system. It includes inner spray water supply and return device 1, outer spray water supply and return device 2, spray quenching device 3, iron oxide skin ditch device 4, return water treatment device 5, cold water pool 6, and control device 7. The inner spray water supply and return device 1 and the outer spray water supply and return device 2 are respectively connected to the spray quenching device 3, the cold water pool device 6, and the control device 7, and the return water treatment device 5 is respectively connected to the oxide scale ditch device 4 and the cold water pool 6 devices, the spray quenching device 3 is connected to the oxide scale ditch device 4, and the internal spray water supply device 1 includes a first pump station 101, a first pipeline filter 102, a first water supply three-way v...

Embodiment 2

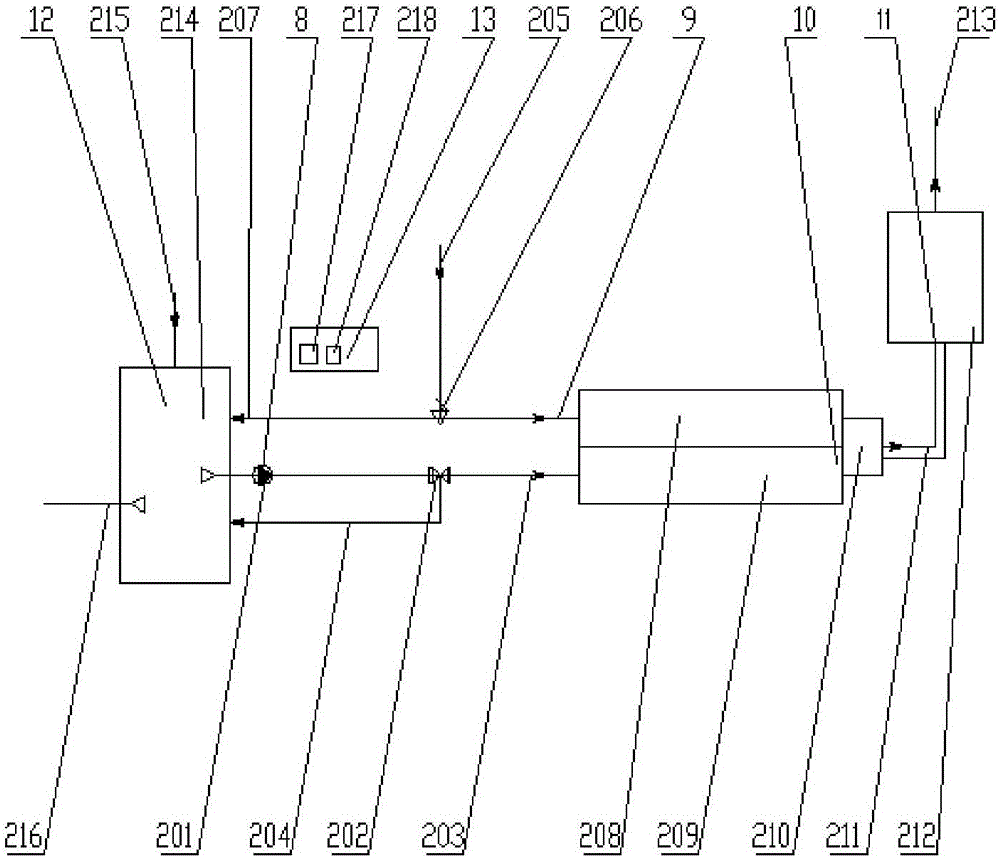

[0104] In this embodiment, in order to make full use of the existing water supply and drainage facilities in the factory area, simplify the equipment composition, and provide an improved quenching equipment suitable for online spraying of steel pipes. From the perspective of the water system, it belongs to independent internal water spraying system.

[0105] Such as figure 2 As shown, the equipment includes an inner spray water supply and return device 8 , an outer spray water supply and return device 9 , a spray quenching device 10 , an oxide scale ditch device 11 , a cold water pool device 12 , and a control device 13 . The inner spray water supply and return device 8 and the outer spray water supply and return device 9 are respectively connected to the spray quenching device 10, the cold water pool device 12, and the control device 13. The spray quenching device 10 is connected to the oxide scale groove device 11, and the internal spray The water supply and return device ...

Embodiment 3

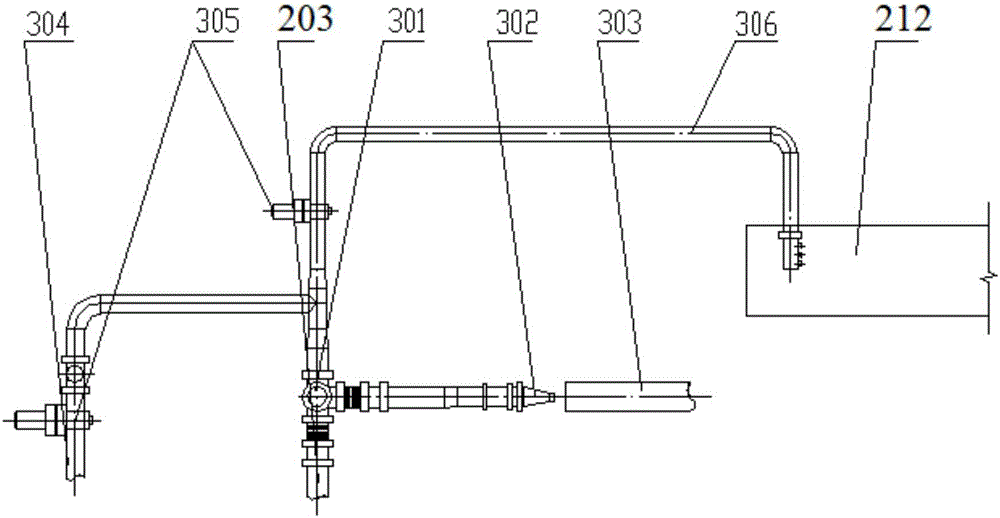

[0123] This embodiment is a further improvement on the basis of Embodiment 2. In actual production, the water discharged from the internal spray quenching does not need to be continuously treated. This embodiment is to save water resource consumption and reduce water treatment costs. design.

[0124] Such as image 3 As shown, in this embodiment, the second internal spray device 209 is connected to the third water supply pipeline 203 in such a way that a third water supply three-way valve 301 is set on the third water supply pipeline 203, and the third water supply three-way valve The water inlet of 301 communicates with the third water supply pipeline 203, the first water outlet of the third water supply three-way valve 301 communicates with the inner spray cone nozzle 302 of the second internal spray device 209, the second of the third water supply three-way valve 301 The water outlets are respectively connected to two branches of the inner spray return pipe 304 and the sla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com