Production process of rice wheat straw graphene for friction material

A technology of rice and wheat straw and production process is applied in the field of production technology of rice and wheat straw graphene, which can solve the problem of high production cost of friction materials, and achieve the effects of no harm to the environment and human body, abundant and readily available raw materials, and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

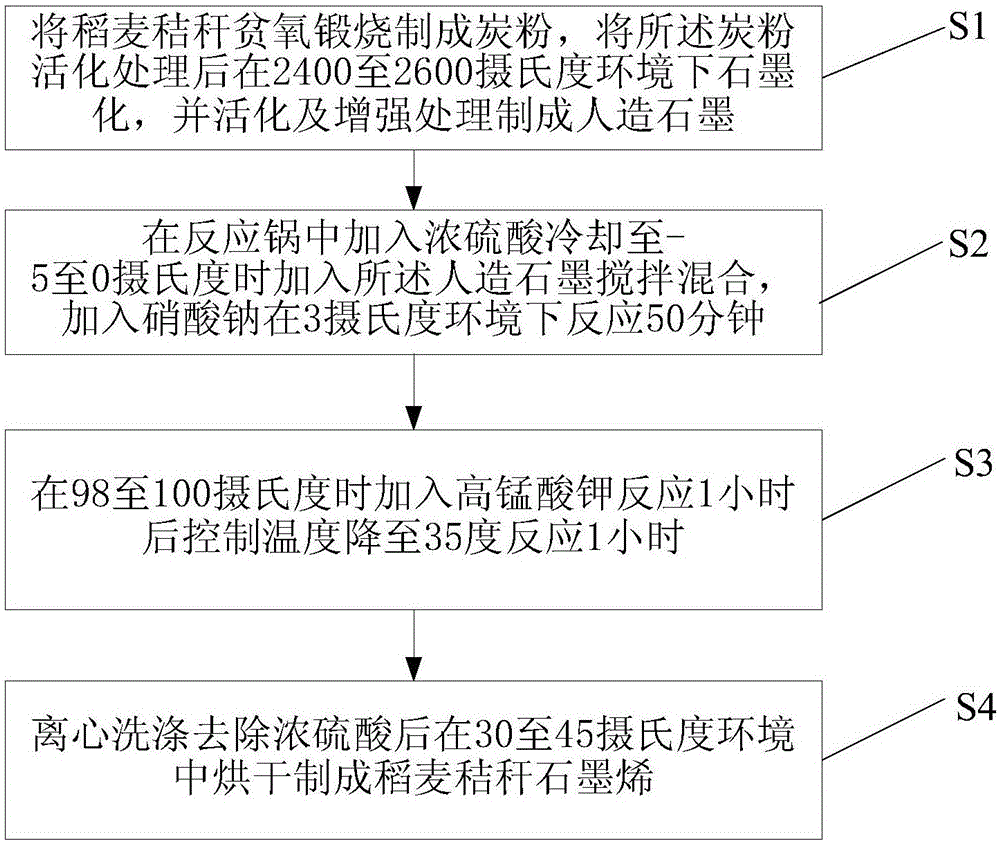

[0015] see figure 1 . The production process of the rice-wheat straw graphene used for the friction material in the preferred embodiment of the present invention comprises steps:

[0016] S1: calcining rice and wheat stalks with poor oxygen to make carbon powder, after activation treatment, the carbon powder is graphitized in an environment of 2400 to 2600 degrees Celsius, and activated and strengthened to make artificial graphite;

[0017] S2: adding concentrated sulfuric acid in the reaction pot and cooling to -5 to 0 degrees Celsius, adding the artificial graphite and stirring and mixing, adding sodium nitrate and reacting for 50 minutes at 3 degrees Celsius;

[0018] S3: at 98 to 100 degrees Celsius, add potassium permanganate to react for 1 hour, then control the temperature to drop to 35 degrees and react for 1 hour;

[0019] S4: Centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com