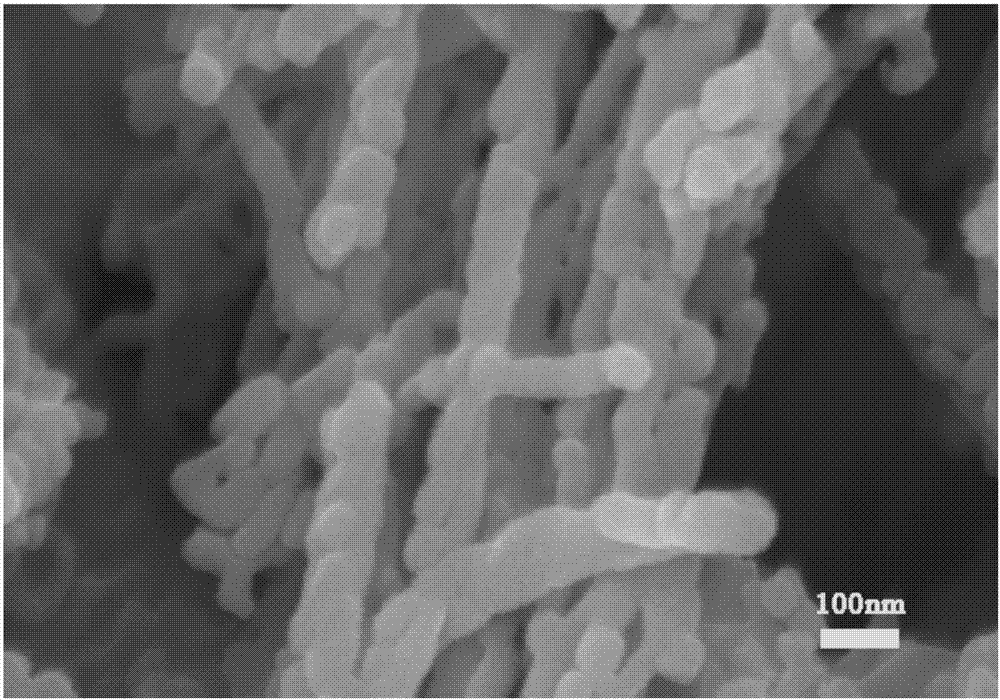

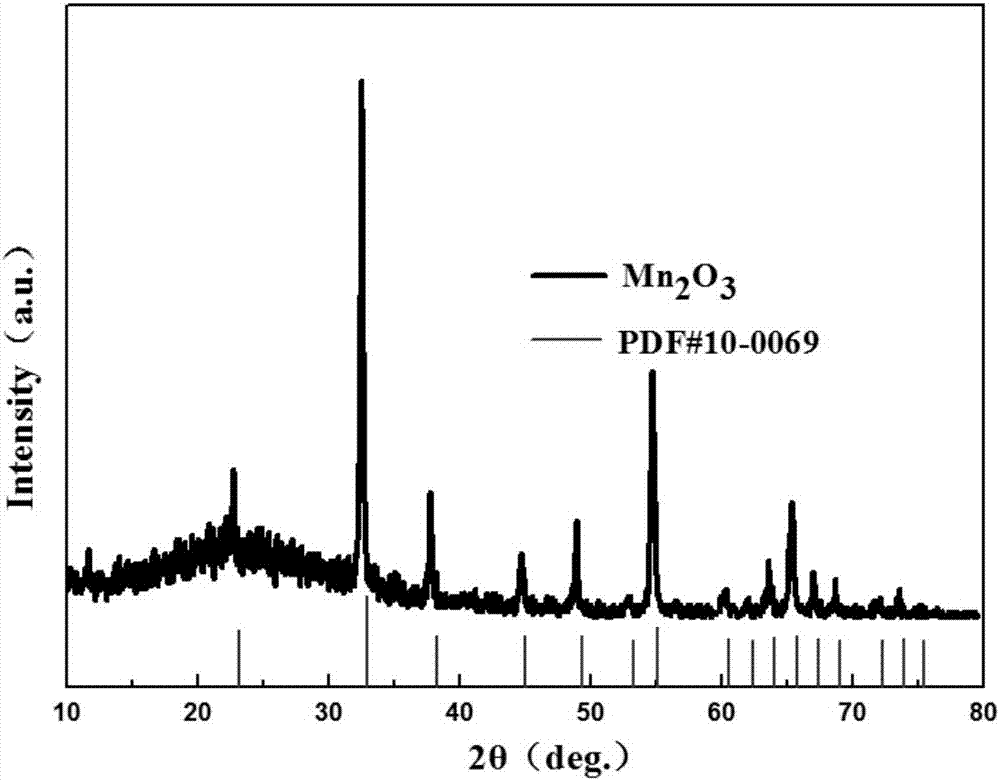

A bamboo structure mn 2 o 3 preparation method

A bamboo joint and solution technology, applied in the field of materials science, can solve the problems of unfavorable high-power charging and discharging, low specific capacity of manganese oxide, etc., and achieve the effects of improving the effective utilization rate, facilitating industrial production and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The invention provides a bamboo structure Mn 2 o 3 A preparation method comprising the steps of:

[0023] 1) The step of preparing the rod-shaped metal-organic framework material Mn-MOF precursor by the directing agent-assisted solvent volatilization method; including the following steps:

[0024] a) Dissolving trimesic acid in an ethanol solution with a volume fraction of 50%, is prepared into a trimesic acid solution whose solution concentration is 0.04mol / L;

[0025] b) dissolving manganese acetate tetrahydrate in an ethanol solution with a volume fraction of 50%, so that the solution concentration is 0.02mol / L;

[0026] c) then take the guiding agent, described guiding agent is polyvinylpyrrolidone, polyethylene glycol 600, emulsifier alkyl polyoxyethylene (10) ether (OP-10), its quality is 3% of manganese acetate solution ; Wherein, the mass ratio of polyvinylpyrrolidone, polyethylene glycol 600 and emulsifier alkyl polyoxyethylene (10) ether (OP-10) three is 2:...

Embodiment 2

[0031] The invention provides a bamboo structure Mn 2 o 3 A preparation method comprising the steps of:

[0032] 1) The step of preparing the rod-shaped metal-organic framework material Mn-MOF precursor by the directing agent-assisted solvent volatilization method; including the following steps:

[0033] a) Dissolving trimesic acid in an ethanol solution with a volume fraction of 50%, is prepared into a trimesic acid solution whose solution concentration is 0.04mol / L;

[0034] b) dissolving manganese acetate tetrahydrate in an ethanol solution with a volume fraction of 50%, so that the solution concentration is 0.02mol / L;

[0035] c) then take the guiding agent, described guiding agent is polyvinylpyrrolidone, polyethylene glycol 600, emulsifier alkyl polyoxyethylene (10) ether (OP-10), its quality is 3% of manganese acetate solution ; Wherein, the mass ratio of polyvinylpyrrolidone, polyethylene glycol 600 and emulsifier alkyl polyoxyethylene (10) ether (OP-10) three is 2:...

Embodiment 3

[0040] The invention provides a bamboo structure Mn 2 o 3 A preparation method comprising the steps of:

[0041] 1) The step of preparing the rod-shaped metal-organic framework material Mn-MOF precursor by the directing agent-assisted solvent volatilization method; including the following steps:

[0042] a) Dissolving trimesic acid in an ethanol solution with a volume fraction of 50%, is prepared into a trimesic acid solution whose solution concentration is 0.04mol / L;

[0043] b) dissolving manganese acetate tetrahydrate in an ethanol solution with a volume fraction of 50%, so that the solution concentration is 0.02mol / L;

[0044] c) then take the guiding agent, described guiding agent is polyvinylpyrrolidone, polyethylene glycol 600, emulsifier alkyl polyoxyethylene (10) ether (OP-10), its quality is 3% of manganese acetate solution ; Wherein, the mass ratio of polyvinylpyrrolidone, polyethylene glycol 600 and emulsifier alkyl polyoxyethylene (10) ether (OP-10) three is 2:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com