Cement-based phase-change waterproof plugging material

A waterproof plugging, cement-based technology, applied in the field of leakage plugging materials, can solve the problems of inconvenient construction for consumers and enterprises, and achieve the effects of convenient and fast construction, stable setting time, and improved performance stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

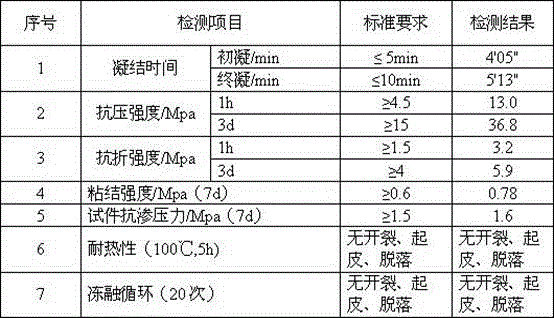

Embodiment 1

[0023] It is prepared from the following components by mass: 50 parts of Portland cement, 46 parts of sulfur-aluminum cement, 2.6 parts of calcium powder, 0.2 part of silica fume, 0.2 part of quick-drying agent, 0.55 part of phase-change special rubber powder, 0.05 part of starch ether, 0.1 part of water reducer, and 0.3 part of osmotic crystallization masterbatch.

[0024] The strength grade of Portland cement is 52.5. The strength grade of sulfur-aluminum cement is 42.5. The specification of calcium powder is 200 mesh. The particle size of silica fume is less than 5% on a 325 mesh sieve. The quick-drying agent uses sodium oleate. Phase-change special rubber powder adopts phase-change microcapsules containing ethylene-vinyl acetate copolymer. The starch ether adopts potato modified starch ether. The water reducing agent adopts sulfonated melamine water reducing agent. The infiltration crystalline masterbatch is a complex of alkali metal salts and complexes.

[0025] Th...

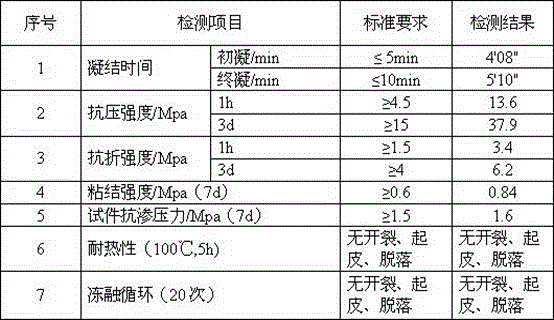

Embodiment 2

[0029] It is prepared from the following components by mass: 36.14 parts of Portland cement, 60 parts of sulfur-aluminum cement, 2.1 parts of calcium powder, 0.2 parts of silica fume, 0.2 parts of quick-drying agent, 0.5 parts of special phase-change rubber powder, 0.06 parts of starch ether, 0.3 parts of water reducer, and 0.5 parts of osmotic crystallization masterbatch.

[0030] The strength grade of Portland cement is 42.5. The strength grade of sulfur-aluminum cement is 42.5. The specification of calcium powder is 325 mesh. The particle size of silica fume is less than 5% on a 325 mesh sieve. The quick-drying agent uses sodium oleate. Phase-change special rubber powder adopts phase-change microcapsules containing ethylene-vinyl acetate copolymer. The starch ether adopts potato modified starch ether. The water reducing agent adopts sulfonated melamine water reducing agent. The infiltration crystalline masterbatch is a complex of alkaline earth metal salts and complex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power level | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com