Novel graphene concrete and preparation method thereof

A graphene and concrete technology, applied in the field of materials, can solve the problems of low flexural strength and poor toughness, and achieve the effects of stable setting time, balanced slump and high physical and chemical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

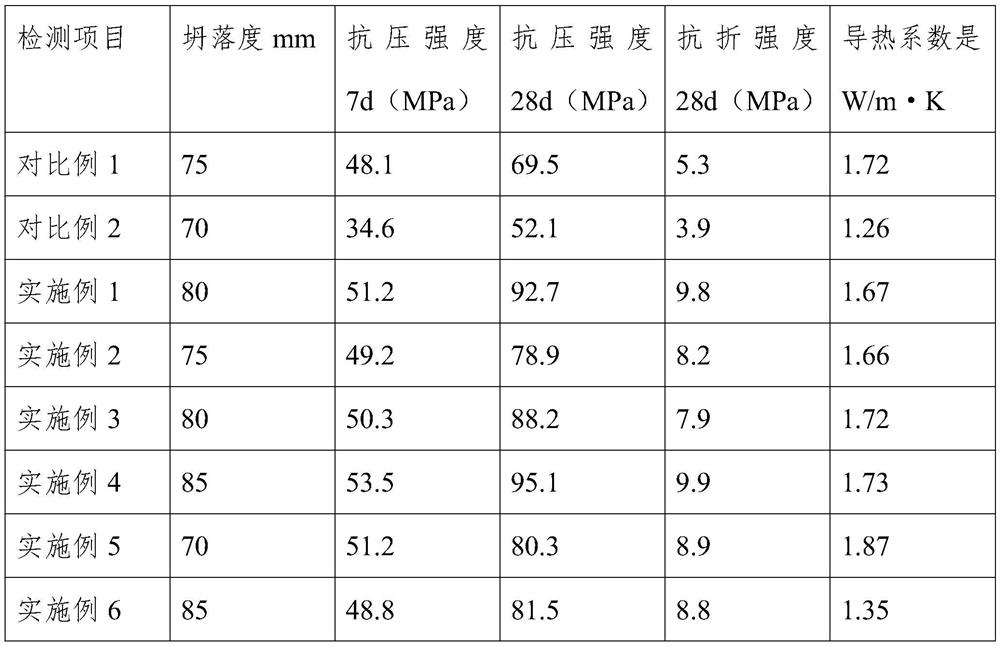

Examples

Embodiment 1

[0019] 1. Preparation of cationic modified graphene

[0020] 1) Take 4kg of graphene oxide, put 100kg of pure water into the mixing tank, stir at 450r / min for 30 minutes, then move the material to a double-layer glass reactor and ultrasonically for 30 minutes, the ultrasonic power is 1.2kW / h.

[0021] 2) Start the constant temperature device, slowly add 10 kg of acrylamide in a water bath at a temperature of 80° C., and react for 24 hours at a speed of 600 r / min.

[0022] 3) Add 8 kg of cationic polyacrylamide to the above materials, stir evenly, and bathe at 60° C. for 10 hours.

[0023] 4) Add 5kg of allylamine and 6kg of acrylate to the cation-modified graphene premix to obtain a cation-modified graphene mixture.

[0024] 2. Preparation of new graphene concrete

[0025] 1) 10kg of cation-modified graphene mixed solution, 40kg of cement, and 30kg of water are fully mixed;

[0026] 2) Add 100kg of gravel and 50kg of fine sand and stir well.

Embodiment 2

[0028] The difference between embodiment 2 and embodiment 1 is that the cationic polymer is polydiallyl dimethyl ammonium chloride.

Embodiment 3

[0030] The difference between embodiment 3 and embodiment 1 is that propionamide is used to prepare cationic modified graphene organic amine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com