Light desulfurization plastering gypsum and its auxiliary agent and preparation method

A technology for plastering gypsum and desulfurization gypsum powder, applied in the field of plastering gypsum, can solve the problems of falling off and cracking, plastering gypsum easily loses powder, etc., and achieves the effects of stable setting time, accelerated aging stability, and scientific mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

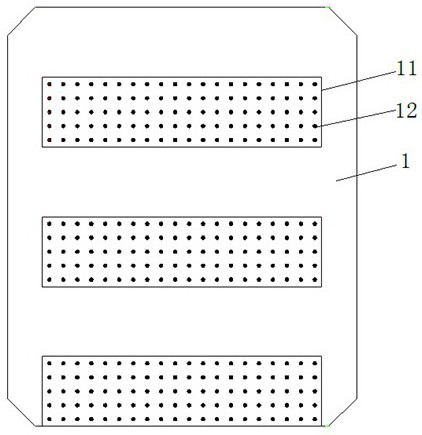

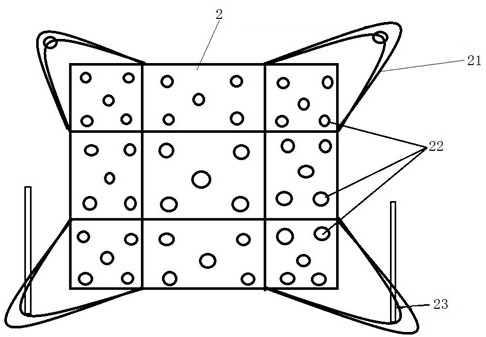

Image

Examples

Embodiment 1

[0063] Step 1: Mix the raw materials according to the following proportions and mix them evenly with a high-speed kneader. The proportions are: heavy calcium 9kg, aging stabilizer 5kg, thixotropic lubricant 0.15kg, water retention agent 0.2kg, The cracked fiber is 0.3 kg, the plasticizer is 0.02 kg, and the anti-crack transcrystallization agent is 0.15 kg, and the total weight is 14.82 kg. Wherein 5kg of aging stabilizer is prepared according to the following formula: 0.5kg of calcium chloride anhydrous, 1kg of quicklime, 1kg of anhydrous aluminum sulfate, and 2.5kg of slaked lime. Thixotropic lubricant 0.15kg is prepared according to the following formula: FP9 starch ether 0.04kg, AE-2 air-entraining agent 0.005kg, LA-01 rheological aid 0.105kg. 0.3kg of anti-crack fiber is prepared according to the following formula: 0.1kg of polypropylene fiber and 0.2kg of wood fiber.

[0064]Step 2: Put 14.82 kg of the above-mentioned small mixed materials, 70 kg of desulfurized gypsum p...

Embodiment 2

[0068] Step 1: Mix the raw materials according to the following proportions, and mix them evenly with a high-speed kneader to obtain small mixed materials. The proportions are: heavy calcium 5kg, aging stabilizer 7kg, thixotropic lubricant 0.15kg, water retention agent 0.2kg, The anti-crack fiber is 0.3 kg, the plasticizer is 0.02 kg, and the anti-crack transcrystallization agent is 0.2 kg, and the total weight is 12.87 kg. Wherein 7kg of aging stabilizer is prepared according to the following formula: 1kg of calcium chloride anhydrous, 1.5kg of quicklime, 2kg of anhydrous aluminum sulfate, and 2.5kg of slaked lime. Thixotropic lubricant 0.15kg is prepared according to the following formula: FP9 starch ether 0.04kg, AE-2 air-entraining agent 0.005kg, LA-01 rheological aid 0.105kg. 0.3kg of anti-crack fiber is prepared according to the following formula: 0.1kg of polypropylene fiber and 0.2kg of wood fiber.

[0069] Step 2: 12.87kg of the above-mentioned mixed materials, 75kg ...

Embodiment 3

[0073] Step 1: Mix the raw materials according to the following proportions, and mix them uniformly with a high-speed kneader to obtain mixed small materials. The proportions are: heavy calcium 3kg, aging stabilizer 7kg, thixotropic lubricant 0.15kg, water retention agent 0.2kg, The anti-crack fiber is 0.3 kg, the plasticizer is 0.02 kg, and the anti-crack transcrystallization agent is 0.25 kg, and the total weight is 10.92 kg. Wherein 7kg of aging stabilizer is prepared according to the following formula: 1kg of calcium chloride anhydrous, 1.5kg of quicklime, 2kg of anhydrous aluminum sulfate, and 2.5kg of slaked lime. Thixotropic lubricant 0.15kg is prepared according to the following formula: FP9 starch ether 0.04kg, AE-2 air-entraining agent 0.005kg, LA-01 rheological aid 0.105kg. 0.3kg of anti-crack fiber is prepared according to the following formula: 0.1kg of polypropylene fiber and 0.2kg of wood fiber.

[0074] Step 2: Put 10.92 kg of the above-mentioned small mixed m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com