Method for preparing febuxostat G crystal form

A febuxostat and crystal form technology, applied in organic chemistry methods, organic chemistry, etc., can solve the problems of high solvent ratio and difficult solvent recovery, and achieve low solvent ratio, low product loss, and reproducibility of the preparation process Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add 20g of febuxostat and 80ml of ethyl acetate to the reaction bottle, then add 8ml of purified water, control the temperature at 75-80°C and stir until it dissolves, then slowly cool down to 5°C, filter, dry in vacuum at 60°C, and discharge , to obtain febuxostat G crystal form 18.8g with a yield of 94.0%. result:

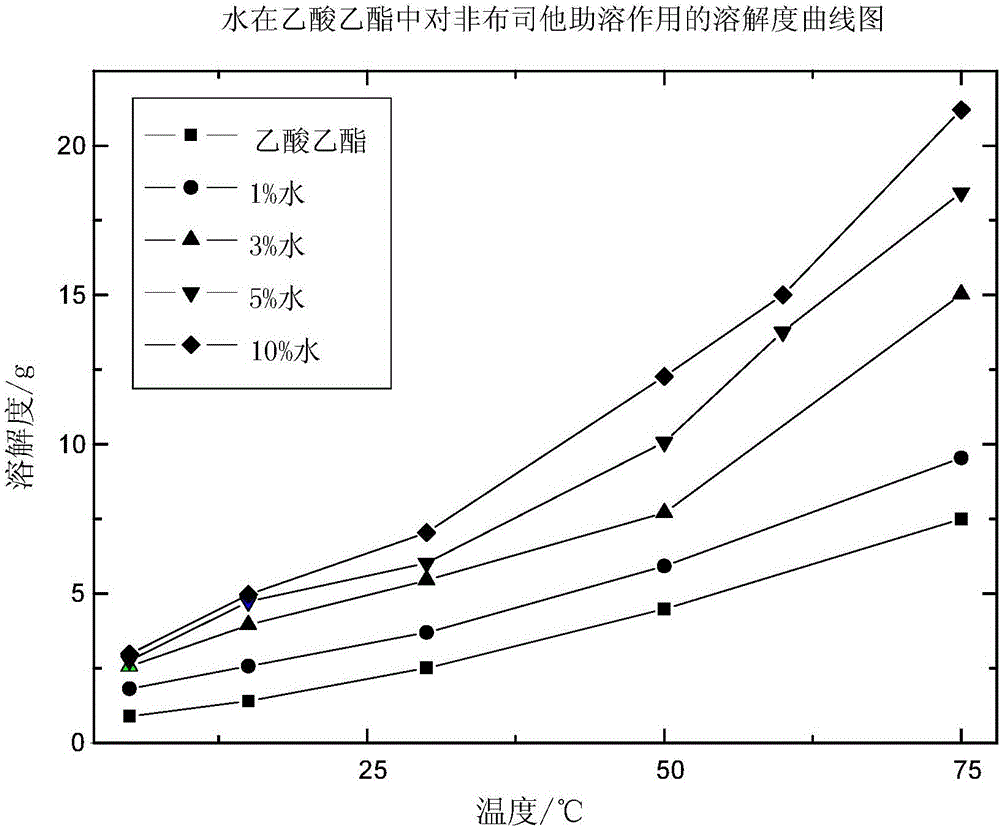

[0034] figure 1 It is the solubility trend diagram of water in ethyl acetate for febuxostat solubilization. It can be seen from the figure that with the increase of water in the solution system, the solubility of febuxostat increases continuously, and the solubility of febuxostat increases at high temperature. The effect is particularly obvious. However, the solubility does not change much at low temperature. Embodiment 1 utilizes this principle to obtain febuxostat with high yield.

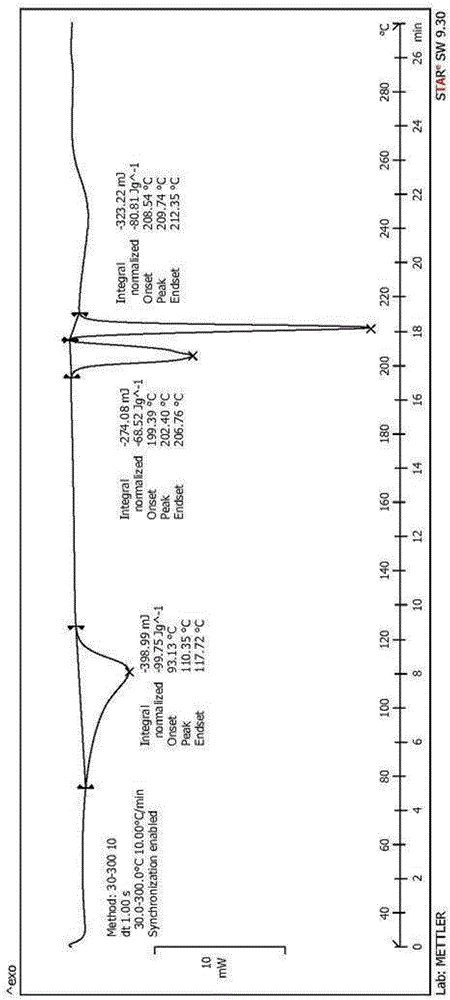

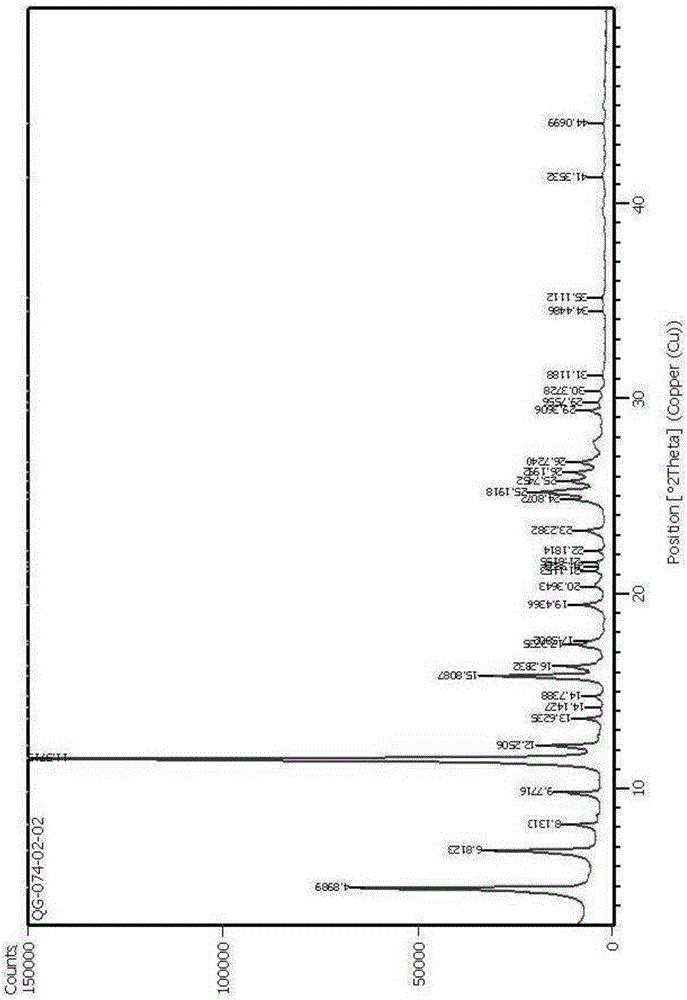

[0035] DSC test, XRD test and FTIR test were performed on the obtained febuxostat G crystal form.

[0036] figure 2 It is the febuxostat G crystal form DSC collection o...

Embodiment 2

[0040] Add 20g of febuxostat and 60ml of isopropyl acetate to the reaction bottle, then add 9ml of purified water, control the temperature at 80-90°C and stir until it dissolves, then slowly cool down to 5°C, filter, and vacuum-dry at 70°C to produce Febuxostat G crystal form 19.2g was obtained, and the yield was 96.0%, which was determined to be Form G crystal form.

Embodiment 3

[0042] Add 20g of febuxostat and 120ml of methyl acetate to the reaction bottle, then add 12ml of purified water, control the temperature at 55-60°C and stir until it dissolves, then slowly cool down to 5°C, filter, dry in vacuum at 65°C, and discharge , 18.9 g of febuxostat G crystal form was obtained, the yield was 94.5%, and it was determined to be Form G crystal form.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com