Environment-friendly indium oxide hydro-thermal synthesis method

An environmentally friendly, hydrothermal synthesis technology, applied in chemical instruments and methods, gallium/indium/thallium compounds, inorganic chemistry, etc., can solve the problems of surfactant loss, product loss, high cost, and reduce surfactants. churn, product loss reduction, emission reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

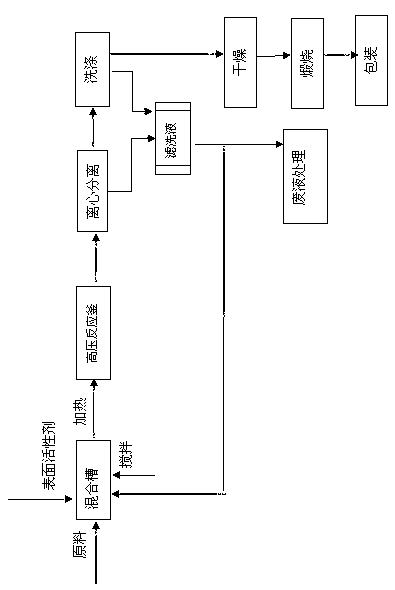

[0021] (1). Preparation of precursor indium hydroxide

[0022] a. Under magnetic stirring conditions, in 70.00ml deionized water, add 0.5006g surfactant and 0.8006g InCl 3 4H 2 O, keep stirring to make it evenly dispersed, add 0.5000g solid NaOH, stir to dissolve it, obtain a uniform solution, continue to stir for 25 minutes,

[0023] b. Then move to a polytetrafluoroethylene container, seal it in a stainless steel autoclave, heat and react at 220°C for 20 hours, then cool to room temperature,

[0024] c. The product is separated by centrifugation and washed, and the precipitate is dried and ground to obtain indium hydroxide In(OH) 3 ;

[0025] (2). Preparation of environmentally friendly indium oxide

[0026] Indium hydroxide In(OH) obtained by drying and grinding 3 Calcined at 500°C for 2 hours to obtain cubic indium oxide;

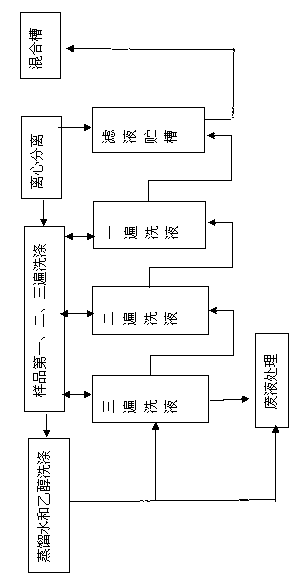

[0027] The filtrate after the centrifugation in the step (1) enters the filtrate storage tank, the sample after the centrifugation is washed t...

Embodiment 2

[0029] (1). Preparation of precursor indium hydroxide

[0030] a. Under magnetic stirring conditions, in 80.00ml deionized water, add 0.8004g surfactant and 0.9008g InCl 3 4H 2 O, keep stirring to make it uniformly dispersed, add 0.8000g solid NaOH and stir to dissolve it, obtain a uniform solution, continue to stir for 30 minutes,

[0031] b. Then move to a polytetrafluoroethylene container, seal it in a stainless steel autoclave, heat and react at 230°C for 18 hours, then cool to room temperature,

[0032] c. The product is separated by centrifugation and washed, and the precipitate is dried and ground to obtain indium hydroxide In(OH) 3 ;

[0033] (2). Preparation of environmentally friendly indium oxide

[0034] Indium hydroxide In(OH) obtained by drying and grinding 3 Calcined at 550°C for 1.5 hours to obtain cubic indium oxide;

[0035] The filtrate after the centrifugation in the step (1) enters the filtrate storage tank, the sample after the centrifugation is ...

Embodiment 3

[0037] (1). Preparation of precursor indium hydroxide

[0038] a. Under the condition of magnetic stirring, in 85.00ml deionized water, add 1.0054g surfactant and 1.0001gInCl 3 4H 2 O, keep stirring to make it evenly dispersed, add 1.0000g of solid NaOH, stir to make it dissolve, obtain a uniform solution, continue to stir for 35 minutes,

[0039] b. Then move to a polytetrafluoroethylene container, seal it in a stainless steel autoclave, heat and react at 250°C for 16 hours, then cool to room temperature,

[0040] c. The product is separated by centrifugation and washed, and the precipitate is dried and ground to obtain indium hydroxide In(OH) 3 ;

[0041] (2). Preparation of environmentally friendly indium oxide

[0042] Indium hydroxide In(OH) obtained by drying and grinding 3 Calcined at 600°C for 1 hour to obtain cubic indium oxide;

[0043]The filtrate after the centrifugation in the step (1) enters the filtrate storage tank, the sample after the centrifugation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com