High-temperature alloy difficult to deform and forging method thereof

A high-temperature alloy, hard-to-deform technology, applied in the direction of metal processing equipment, etc., can solve the problems of large product loss and poor quality, and achieve the effect of reducing product loss, uniform structure and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

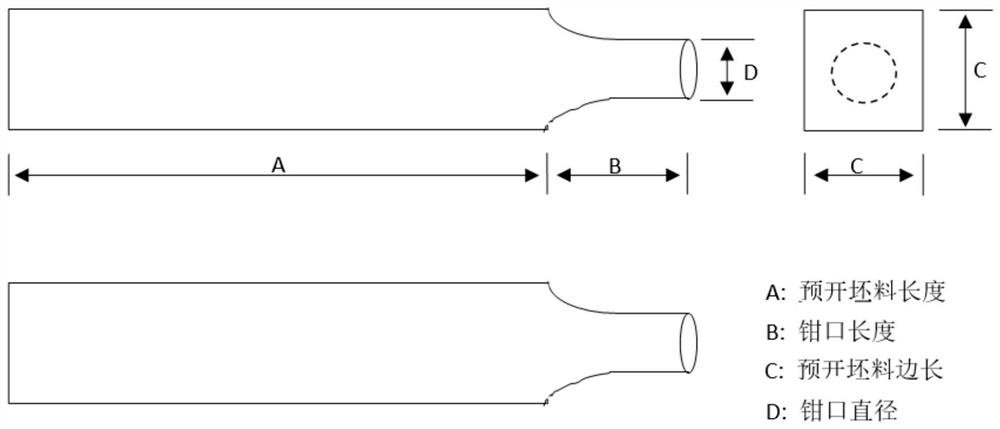

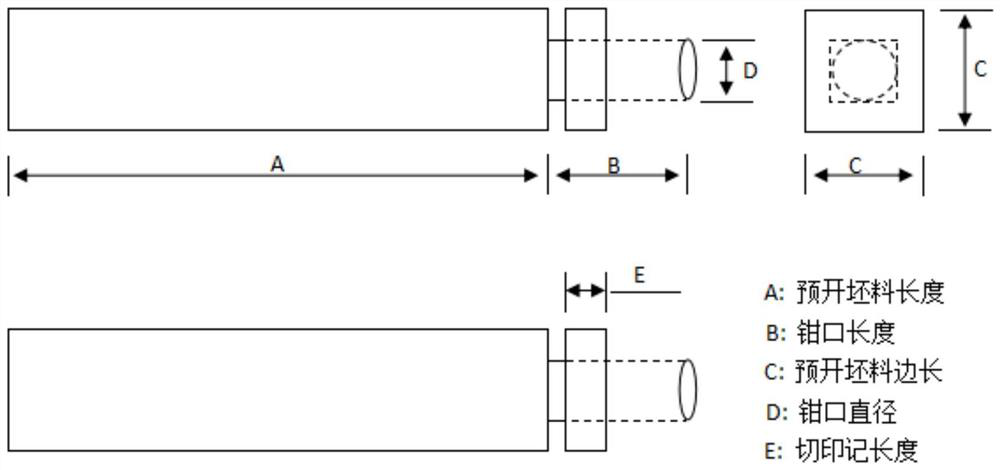

Image

Examples

Embodiment 1

[0045] Implementation example 1 of the present invention utilizes GH4698 alloy φ638mm consumable ingot to produce φ265mm rod, the manufacturing process of φ250mm after lathing, the specification of required finished product: φ250mm. Include the following steps:

[0046] Step 1: Furnace loading of steel ingots: Put the φ638mm self-consumable steel ingots into the heating furnace according to the process requirements to heat the steel ingots. The heating temperature is 1140-1180°C, and the holding time is 3-5h. Among them, the mass percentage of each element composition of the steel ingots is: C: 0.05; Si: 0.04; Mn: 0.02; Cr: 14.56; Ni: Yu; Mo: 2.97; P: 0.003; S: 0.001; 0.54.

[0047] Step 2: Tooling preparation: before production on the 45MN fast forging machine, the forging anvil, chopping knife, and throwing tools must be fully prepared and installed on the tooling track of the fast forging machine. And the outer ones are forging anvil, chopping knife and throwing son in tu...

Embodiment 2

[0056] Implementation example 2 of the present invention utilizes GH4141 alloy φ508mm self-consumable ingot to produce φ265mm rod, the manufacturing process of φ250mm after lathing, the specification of required finished product: φ250mm. Include the following steps:

[0057] Step 1: Steel ingot loading: Put the φ508mm consumable steel ingot into the heating furnace according to the process requirements to heat the steel ingot. The heating temperature is 1150-1180°C, and the holding time is 2-3h. Among them, the mass percentage of each element composition of the steel ingot is: C: 0.08; Si: 0.03; Mn: 0.03; Cr: 19.03; Ni: Yu; Mo: 9.71; P: 0.002; S: 0.001; 0.44.

[0058] Step 2: Tooling preparation: before production on the 45MN fast forging machine, forging anvils, chopping knives, and throwing tools must be fully prepared and installed on the tooling track of the fast forging machine; And the outer ones are forging anvil, chopping knife and throwing son in turn.

[0059] Ste...

Embodiment 3

[0067] Example 3 of the present invention utilizes GH4698 alloy φ638mm self-consumable ingot to produce φ315mm rod, the manufacturing process of φ300mm after lathing, the specification of the required finished product: φ300mm. Include the following steps:

[0068] Step 1: Steel ingot loading: Put the φ638mm self-consumable steel ingot into the heating furnace according to the process requirements to heat the steel ingot. The heating temperature is 1140-1180°C, and the holding time is 3-5 hours. Among them, the mass percentage of each element composition of the steel ingot is: C: 0.05; Si: 0.04; Mn: 0.02; Cr: 14.56; Ni: Yu; Mo: 2.97; P: 0.003; ; Nb: 2.07; Cu: 0.02; Fe: 0.54.

[0069] Step 2: Tooling preparation: before production on the 45MN fast forging machine, the forging anvil, chopping knife, and throwing tools must be fully prepared and installed on the tooling track of the fast forging machine. And the outer ones are forging anvil, chopping knife and throwing son in tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com