Synthesis method of 2'-oxydiethylamine and product thereof

A technology of oxydiethylamine and oxydiethylamine hydrochloride, which is applied in the field of synthesis of 2'-oxydiethylamine, can solve the problem that the purity of the product is not specified, there is not much synthesis and research work, and there are many raw materials and other problems, to achieve the effect of difficult to deal with, simplify the operation process and reduce the loss of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

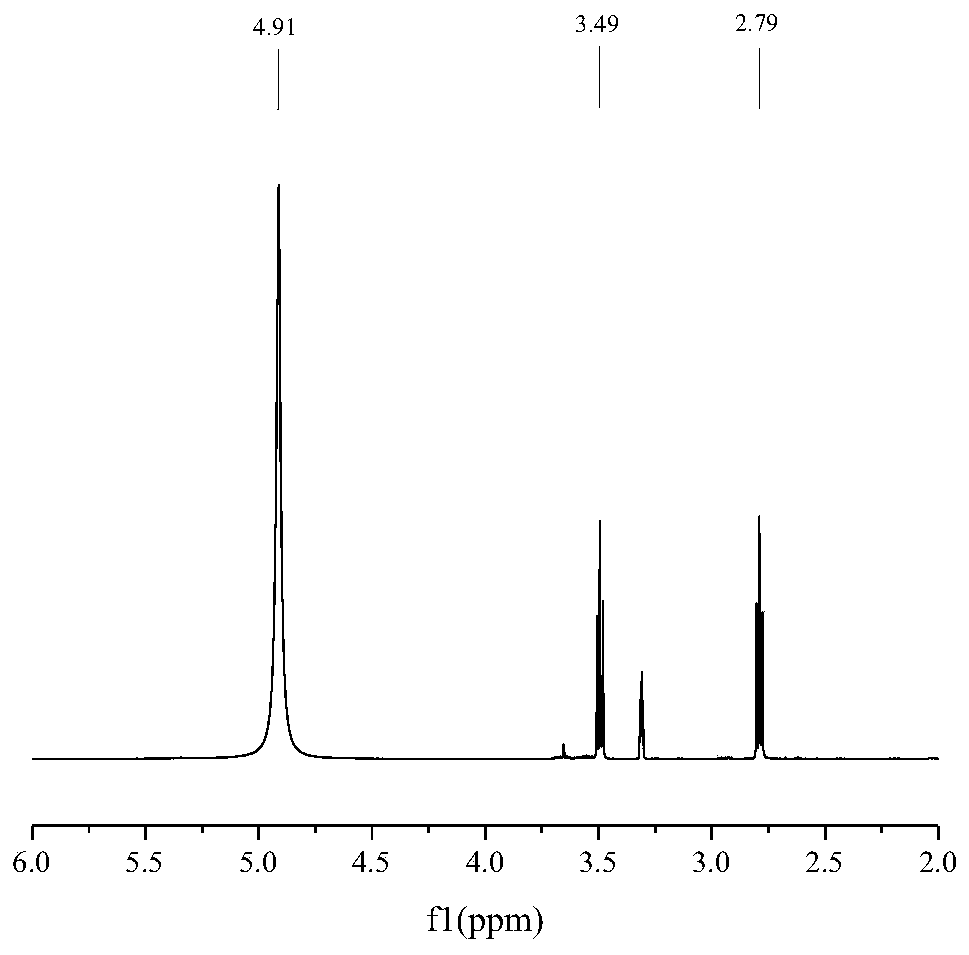

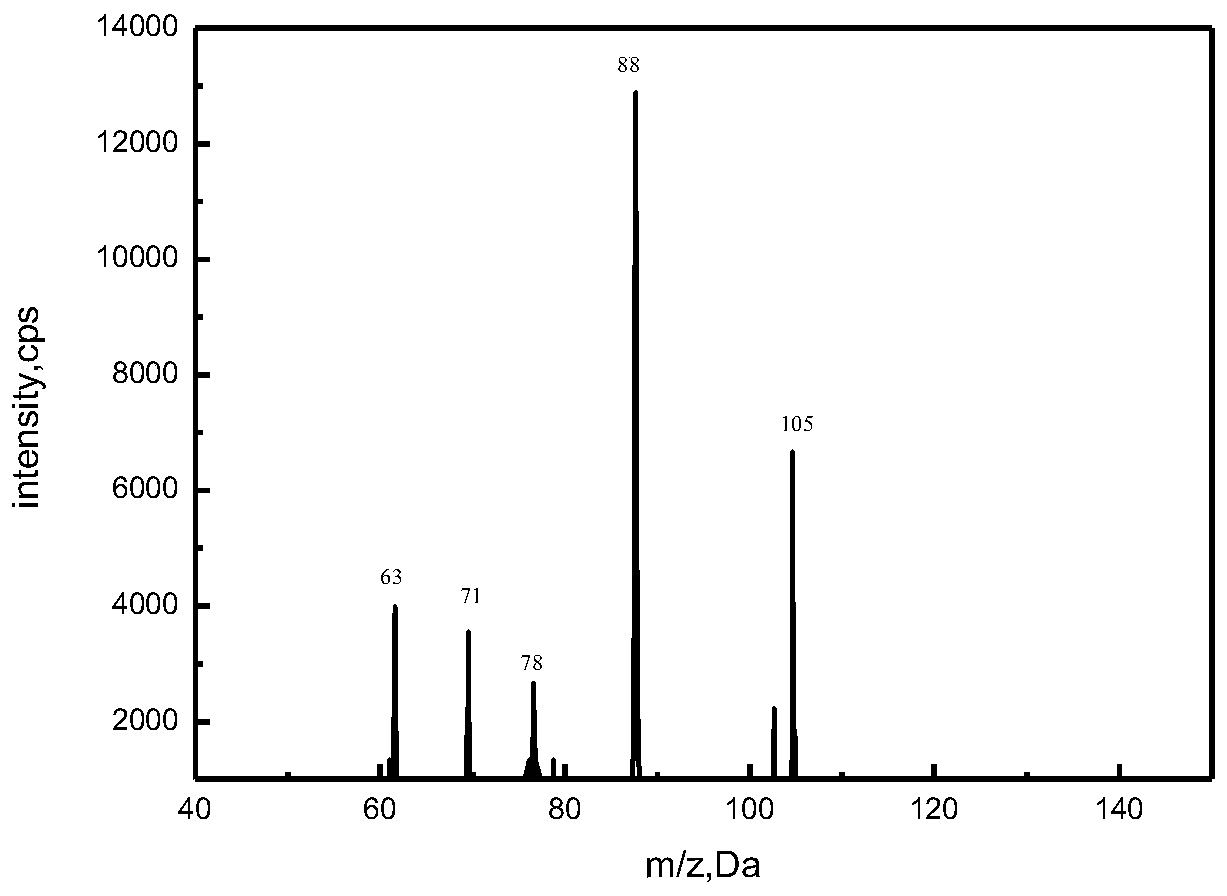

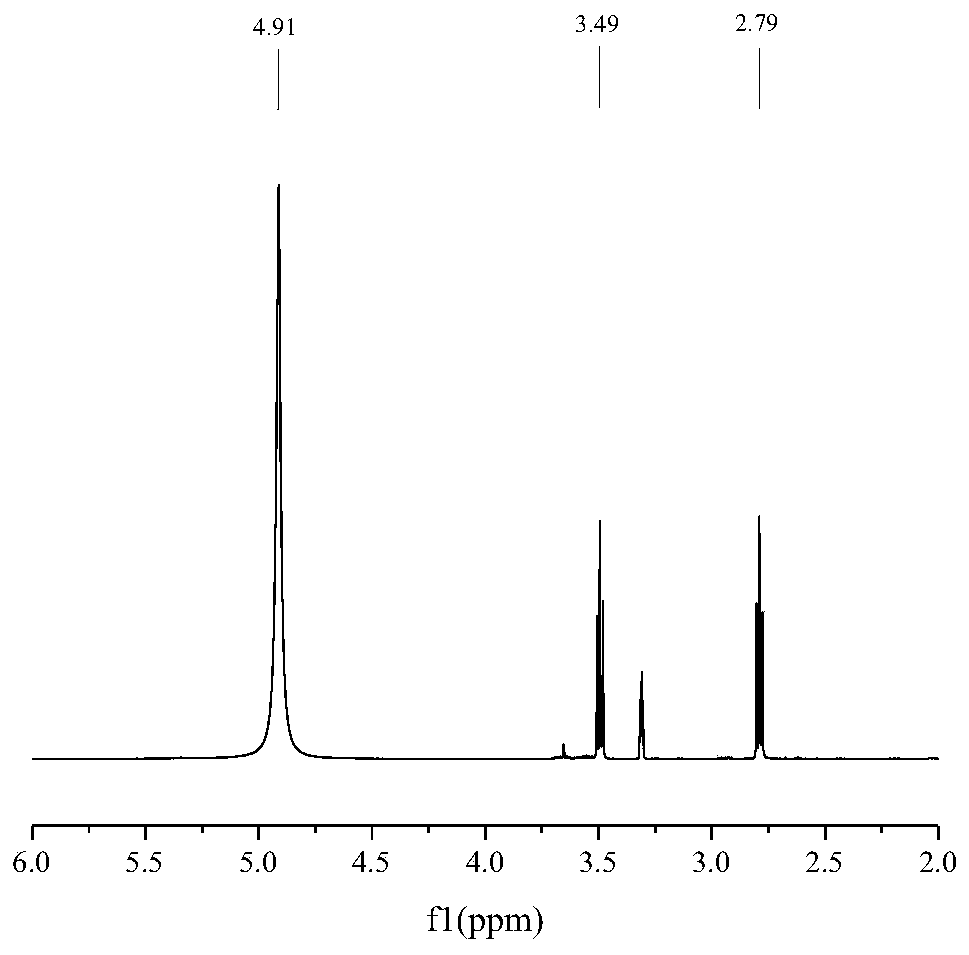

Image

Examples

Embodiment 1

[0049] (1) Synthesis process of 2,2'-diphthalimide diethyl ether

[0050] Dissolve 300g (2.1mol) of dichlorodiethyl ether and 777g (4.2mol) of potassium phthalimide in 1500g of DMF solvent, place in a round bottom flask, heat to 65°C, and stir for 6 hours. The reaction process The solid gradually dissolves in the medium, and the solution becomes milky white, that is, the crude product solution of 2,2'-diphthalimide diethyl ether; add 10L deionized water to the above solution, stir for 2 hours, a white solid precipitates, and filter it with suction Finally, the white solid was washed three times with deionized water, and dried at 60°C for 10 h to obtain 613 g of a white solid of 2,2'-diphthalimide diethyl ether. Theoretically, 765 g should be formed, and the product yield was 613 / 765*100%=80.25%.

[0051] (2) Synthetic process of 2'-oxydiethylamine

[0052] Take 100g of dried 2,2'-diphthalimide diethyl ether and 80g of hydrazine hydrate in a 2L round bottom flask, add 1L of ...

Embodiment 2

[0054] (1) Synthesis process of 2,2'-diphthalimide diethyl ether

[0055] Add 300g (2.1mol) dichloroethyl ether, 777g (4.2mol) potassium phthalimide and 1500g DMF solvent into a 3L round bottom flask, heat to about 65°C, stir for 8 hours, and the solid gradually dissolves during the reaction , the solution turned milky white. After the reaction was completed, 10 L of deionized water was added and the reaction solution was stirred for 4 hours, and a white solid was precipitated. After suction filtration, the white solid was washed with deionized water three times, and dried at 60° C. for 10 hours. 655 g of the product 2,2'-diphthalimide diethyl ether was obtained as a white solid, and the yield was calculated to be 85.61%.

[0056] (2) Synthetic process of 2'-oxydiethylamine

[0057] Take 100g of dried 2,2'-diphthalimide diethyl ether and 80g of hydrazine hydrate in a 2L round bottom flask, add 1L of absolute ethanol solvent, stir and reflux at 75°C for 2h, the white solid di...

Embodiment 3

[0059] (1) Synthesis process of 2,2'-diphthalimide diethyl ether

[0060] Add 300g (2.1mol) dichloroethyl ether, 777 (4.2mol) potassium phthalimide and 1500g DMF solvent into a 3L round bottom flask, heat to about 65°C, stir for 12 hours, and the solid gradually dissolves during the reaction , the solution turned milky white. After the reaction was completed, 10 L of deionized water was added and the reaction solution was stirred for 2 hours, and a white solid was precipitated. After suction filtration, the white solid was washed with deionized water three times, and dried at 60° C. for 10 hours. 721 g of the product 2,2'-diphthalimide diethyl ether was obtained as a white solid, and the yield of 2,2'-diphthalimide diethyl ether was calculated to be 94.37%.

[0061] (2) Synthetic process of 2'-oxydiethylamine

[0062] Take 100g of dried 2,2'-diphthalimide diethyl ether and 80g of hydrazine hydrate in a 2L round bottom flask, add 1L of absolute ethanol solvent, stir and reflu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com