A kind of solder resist ink for LED exposure machine and preparation method thereof

A technology of solder resist ink and exposure machine, which is applied in the direction of optomechanical equipment, ink, optics, etc. It can solve the problems of high energy consumption, long start-up time and exposure time, and the singleness of the light source of LED exposure machine, etc., and achieve high adhesion , Low odor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

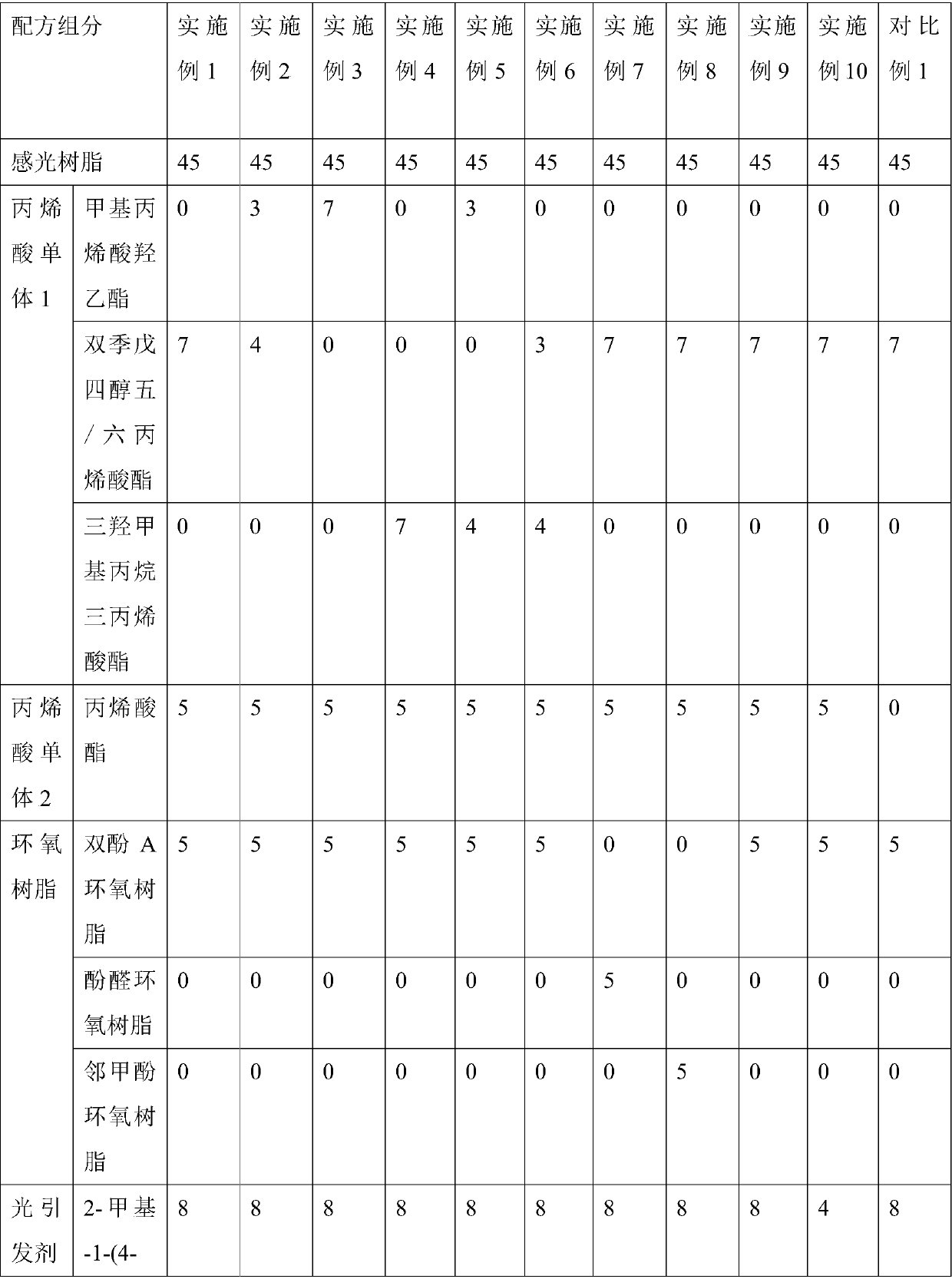

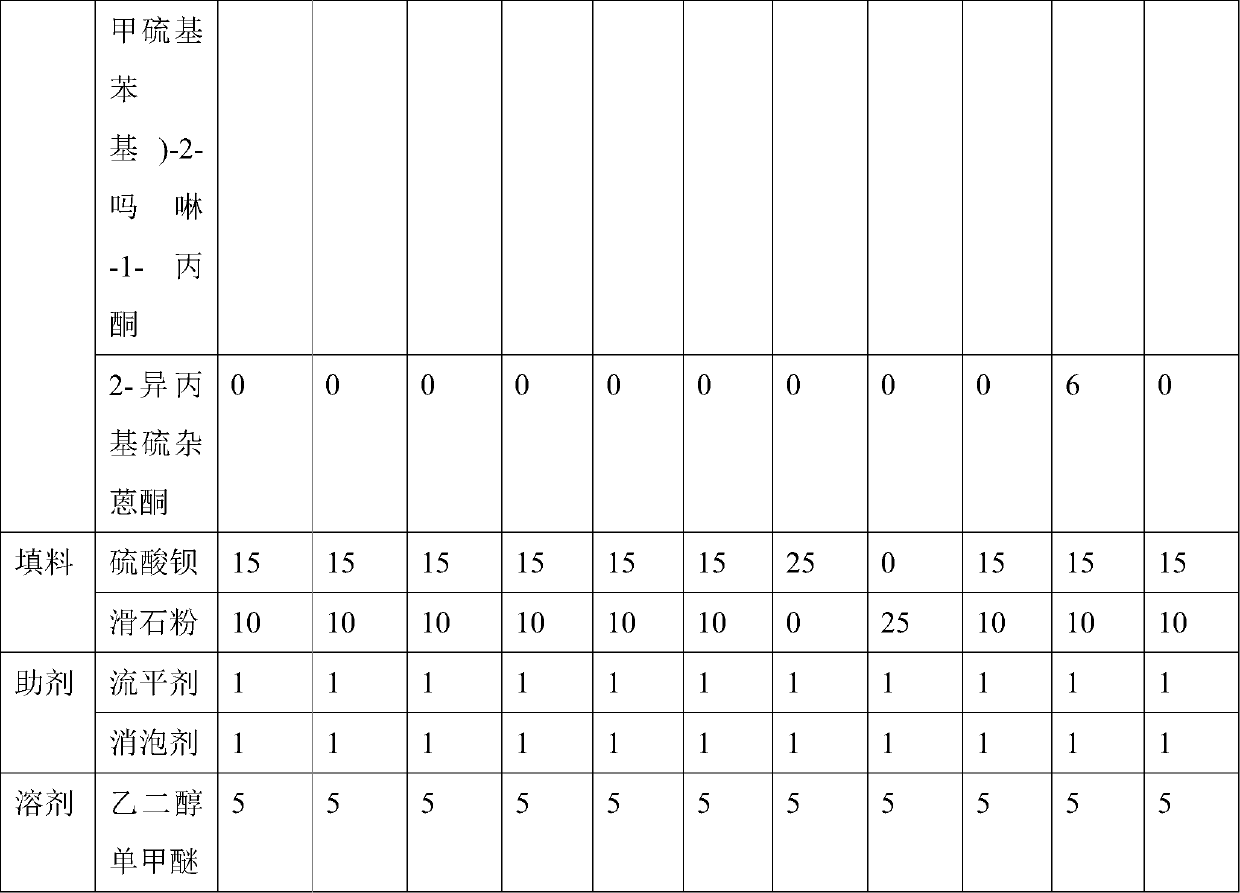

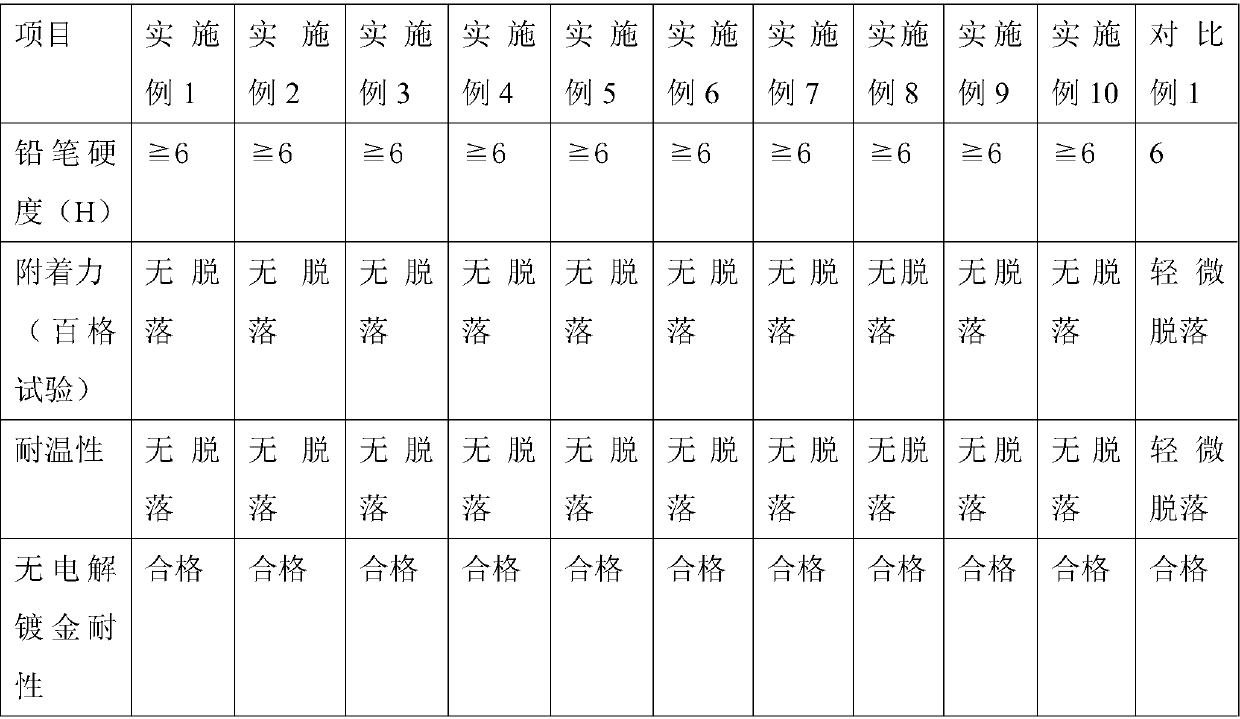

[0037] A solder resist ink for an LED exposure machine, comprising the components shown in Table 1 in parts by weight.

[0038] The preparation method of the photosensitive resin is: by weight, 300 parts of solvent, 300 parts of epoxy resin, 110 parts of acrylic acid, 0.1 part of hydroquinone are added in the reaction kettle, heated to 105 ° C, and then the catalyst amine is added, After reacting for 10 hours, 60 parts of tetrahydrophthalic anhydride was finally added and reacted for another 4 hours to finally obtain a photosensitive resin with an acid value of 50 mgKOH / g and a solid content of 60%.

[0039] A preparation method of solder resist ink for LED exposure machine, comprising the following steps:

[0040] (1) Take photosensitive resin, acrylic monomer 1, acrylic monomer 2, epoxy resin, photoinitiator, auxiliary agent, solvent, pigment and filler by weight;

[0041] (2) each component weighed in the step (1) was dispersed for 50 minutes with a dispersion speed of 600...

Embodiment 9

[0053] A solder resist ink for an LED exposure machine, comprising the components shown in Table 1 in parts by weight.

[0054] The preparation method of the photosensitive resin used is: by weight, 300 parts of solvent, 280 parts of epoxy resin, 110 parts of acrylic acid, 0.1 part of hydroquinone are added to the reaction kettle, heated to 105 ° C, and then the catalyst is added Bean amine, reacted for 10 hours, finally added 100 parts of tetrahydrophthalic anhydride, and reacted for another 4 hours to finally obtain a photosensitive resin with an acid value of 55 mgKOH / g and a solid content of 62%.

[0055] The method for preparing the solder resist ink for LED exposure machine is the same as that of Example 1.

[0056] The method of printing the solder resist ink with the LED exposure machine on the PCB to form a solder resist film is the same as that in Example 1.

Embodiment 10

[0058] A solder resist ink for an LED exposure machine, comprising the components shown in Table 1 in parts by weight.

[0059]The preparation method of the photosensitive resin used is: by weight, 300 parts of solvent, 320 parts of epoxy resin, 110 parts of acrylic acid, 0.1 part of hydroquinone are added to the reaction kettle, heated to 105 ° C, and then the catalyst is added Bean amine, reacted for 10 hours, finally added 60 parts of tetrahydrophthalic anhydride, reacted for 4 hours, finally obtained the photosensitive resin with an acid value of 55mgKOH / g and a solid content of 62%.

[0060] The method for preparing the solder resist ink for LED exposure machine is the same as that of Example 1.

[0061] The method of printing the solder resist ink with the LED exposure machine on the PCB to form a solder resist film is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com