A method and device for roasting low-quality coal to extract vanadium and pure oxygen

A low-quality coal, pure oxygen technology, applied in the direction of improving energy efficiency, improving process efficiency, waste heat treatment, etc., can solve the problems of waste heat resources, insufficient combustion, incomplete oxidation, etc., to improve combustion temperature and reduce emissions. Smoke loss, the effect of promoting oxidative combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

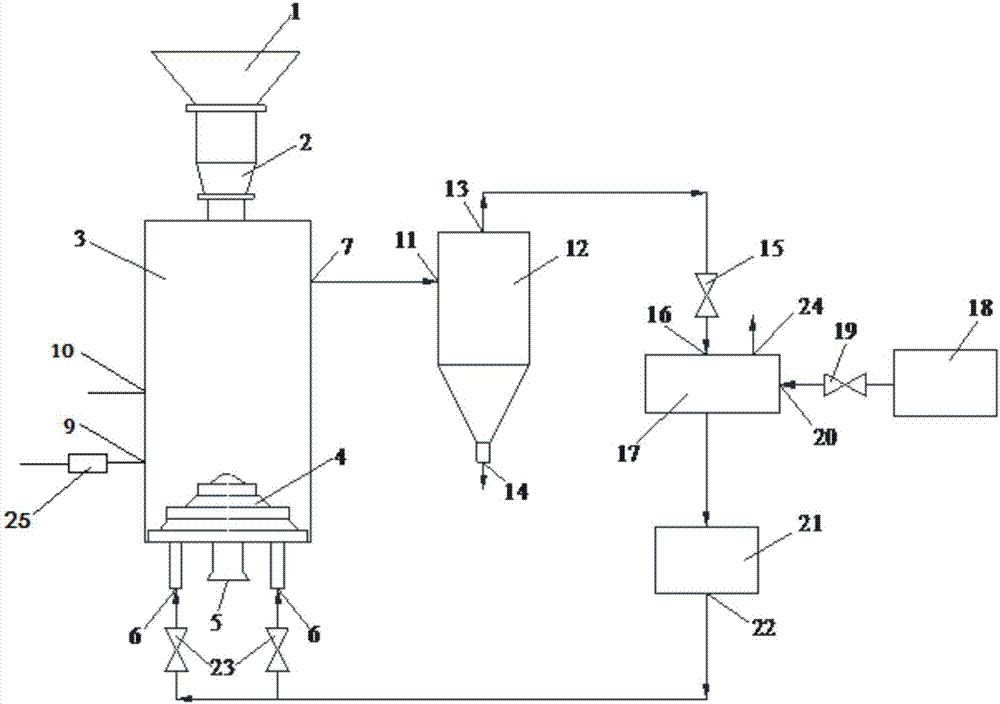

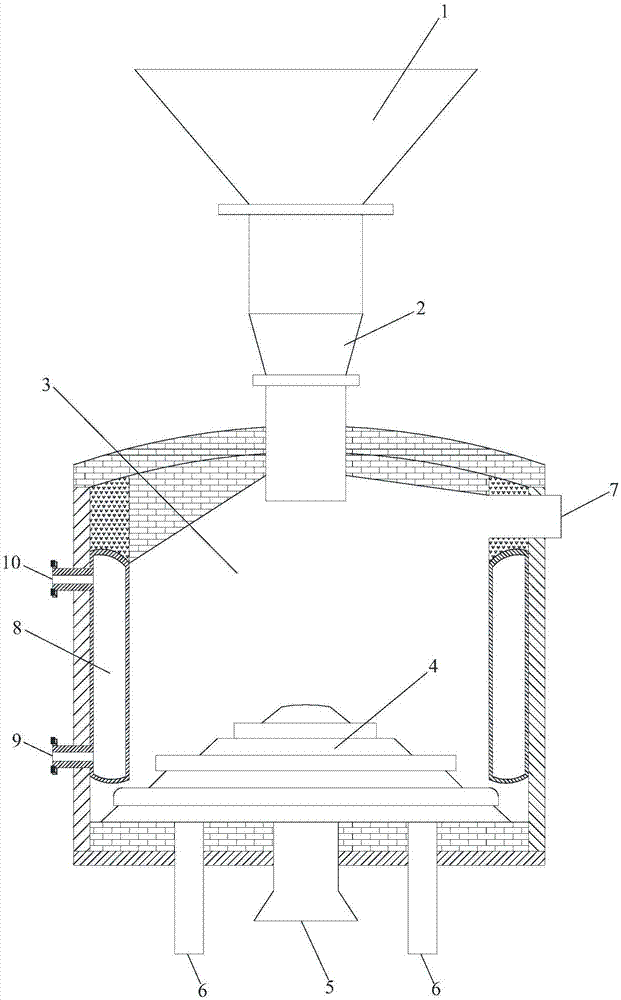

[0018] Such as Figure 1-2 As shown, a device used in a method for extracting vanadium from low-quality coal and roasting with pure oxygen includes an oxygen system 18, an oxygen preheating system 17, a hot oxygen pressure regulating system 21, a roasting furnace 3, and a dust collector 12 connected in sequence.

[0019] The top of the roasting furnace 3 is provided with a storage bin 1 and a feeding device 2, the interior of the roasting furnace 3 is provided with a grate 4, the interior of the furnace wall of the roasting furnace 3 is provided with a water-cooled jacket 8, and the lower part of the water-cooled jacket 8 is provided with a jacket water The inlet 9 and the upper part of the water-cooling jacket 8 are provided with a jacket water outlet 10, and the jacket water outlet is externally connected to a steam-water separator.

[0020] The bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com