Novel pulverized coal boiler low-nitrogen combustion system

A low-nitrogen combustion, pulverized coal boiler technology, applied in the direction of using a variety of fuel combustion, combustion types, combustion equipment, etc., can solve the limited range of NOx emissions, insufficient boiler potential, and difficulty in meeting the air pollutant emission requirements of power plant boilers, etc. problem, to achieve the effect of reducing NOx

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

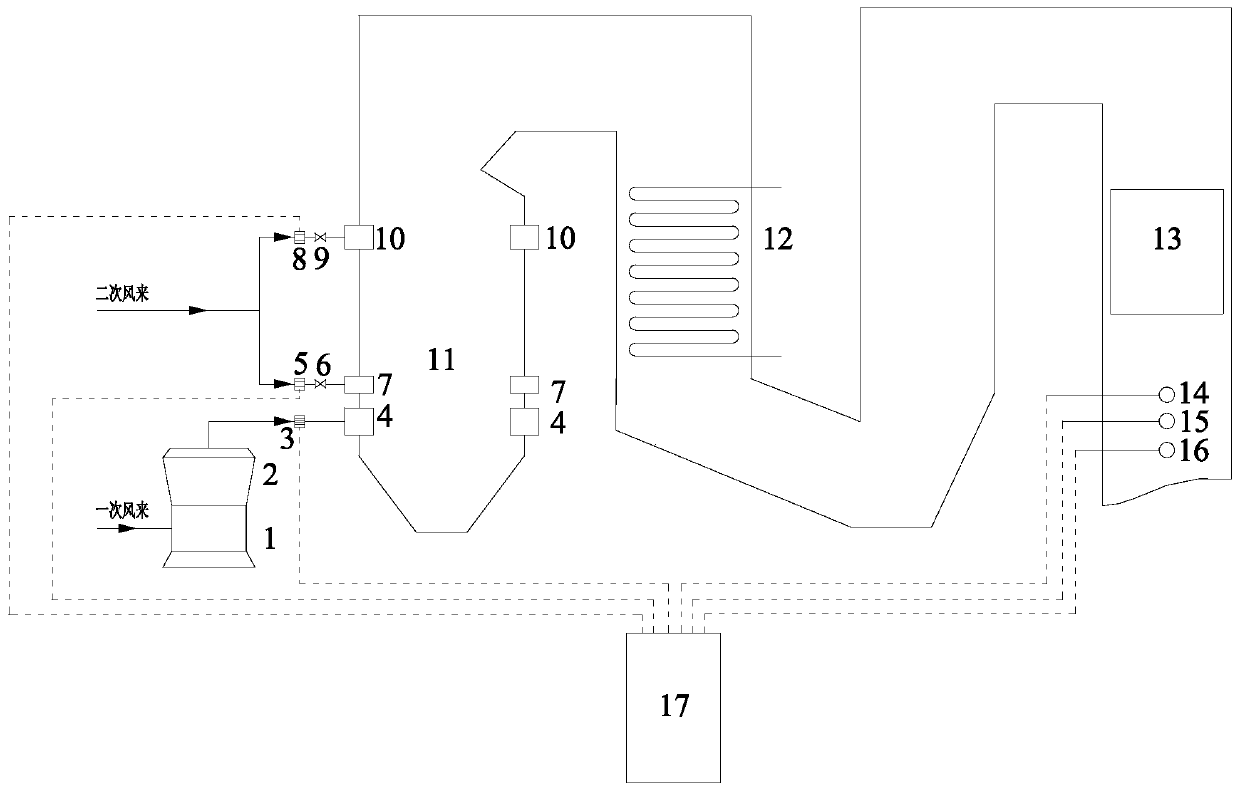

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] see figure 1 , the pulverized coal boiler low-nitrogen combustion system provided by the present invention includes an ultra-fine coal pulverizer 1, a high-efficiency separator 2, an air powder online device 3, a high-efficiency low-nitrogen combustion device with wall-attached air 4, a secondary air Measuring device 5, secondary air regulating damper 6, secondary air nozzle 7, overburning air measuring device 8, overburning air regulating door 9, overburning air nozzle 10, furnace 11, heating surface with catalytic spray coating 12, Catalyst 13 with catalytic oxidation of CO; online O 2 Measuring device 14 , online CO measuring device 15 , online NOx measuring device 16 and industrial computer 17 .

[0028] Among them, a high-efficiency low-nitrogen combustion device 4 with wall-attached air, a secondary air nozzle 7 and an overburning air nozzle 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com