Preparation method of inflorescence type WO3 thin film for electrochromism

An electrochromic and flower-cluster technology, applied in liquid chemical plating, metal material coating process, coating, etc., can solve the problems of complex film preparation methods, and achieve environmental protection, low energy loss, and overall cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] First, 1.2 g of Na 2 WO 4 2H 2 O was dissolved in distilled water, and the volume was adjusted to 100ml to prepare 0.036mol L -1 Na 2 WO 4 Aqueous solution, to 100ml Na 2 WO 4 Add 0.2g NaCl to the aqueous solution, stir until transparent, add 1mol·L -1 hydrochloric acid to adjust the pH value to 3; then add 0.02g CTAB as a surfactant, after stirring for a period of time to obtain WO 3 precursor solution. WO 3 The precursor solution was transferred to a hydrothermal kettle with a polytetrafluoroethylene liner, and the cleaned FTO conductive glass was placed in the solution, covered and sealed, heated to 180°C in an oven for 24 hours, and then cleaned with absolute ethanol , distilled water and then washed and dried. WO 3 The film was annealed at 550°C in a muffle furnace to obtain flower-like WO 3 film.

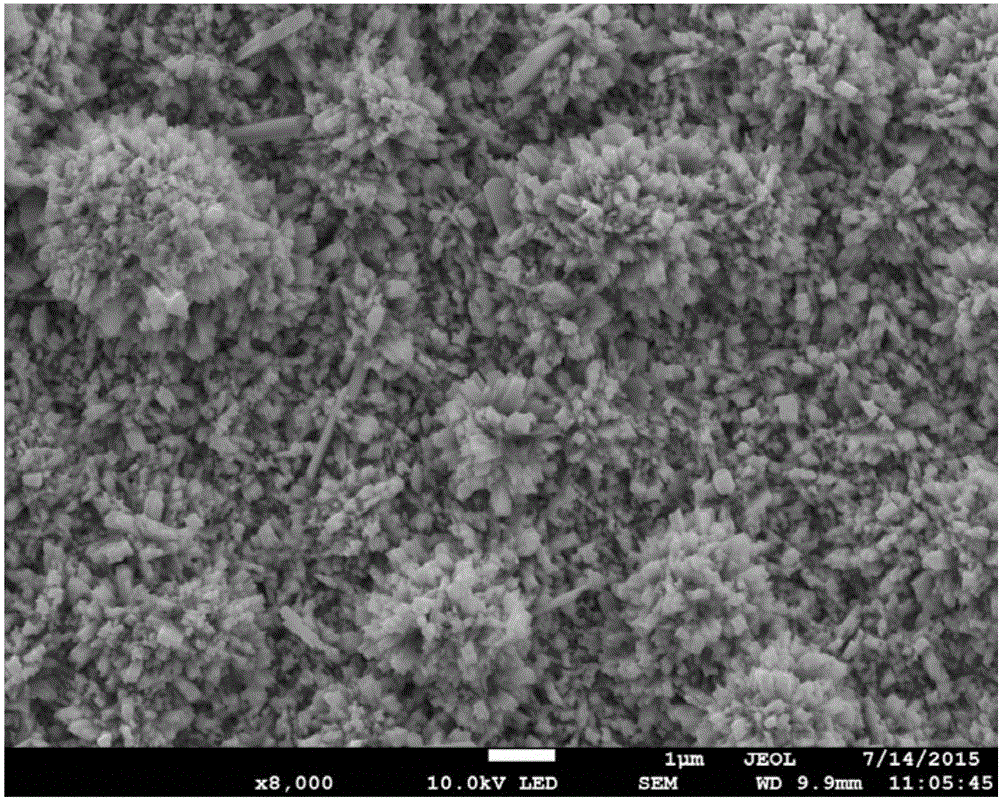

[0026] The flower cluster WO obtained by the present invention 3 Thin film, scanning electron microscope observation test results such as figure 1 As sho...

Embodiment 2

[0028] First, prepare 0.03mol·L -1 Na 2 WO 4 100ml of aqueous solution, add 0.1g NaCl and stir until transparent, add 1mol·L -1 hydrochloric acid to adjust the pH value to 3; then add 0.01gCTAB as a surfactant, after stirring for a period of time to obtain WO 3 precursor solution. WO 3 The precursor solution was transferred to a hydrothermal kettle with a polytetrafluoroethylene liner, and the cleaned FTO conductive glass was placed in the solution, covered and sealed, heated to 180°C in an oven for 24 hours, and then cleaned with absolute ethanol , distilled water and then washed and dried. WO 3 The film was annealed at 550°C in a muffle furnace to obtain flower-like WO 3 film.

Embodiment 3

[0030] First, prepare 0.04mol·L -1 Na 2 WO 4 100ml of aqueous solution, add 0.2g NaCl and stir until transparent, add 1mol·L -1 Hydrochloric acid to adjust the pH value to 3; then add 0.015gCTAB as a surfactant, after stirring for a period of time to obtain WO 3 precursor solution. WO 3 The precursor solution was transferred to a hydrothermal kettle with a polytetrafluoroethylene liner, and the cleaned FTO conductive glass was placed in the solution, covered and sealed, heated to 180°C in an oven for 24 hours, and then cleaned with absolute ethanol , distilled water and then washed and dried. WO 3 The film was annealed at 550°C in a muffle furnace to obtain flower-like WO 3 film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap