Externally-controlled isolation type double air-chamber hydro-pneumatic suspension cylinder

A technology of oil-air suspension and double air chambers, applied in the direction of gas-hydraulic shock absorbers, springs, shock absorbers, etc., can solve problems such as limitations, lack of structural foundation and conditions, and no consideration of external input ports and internal control links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

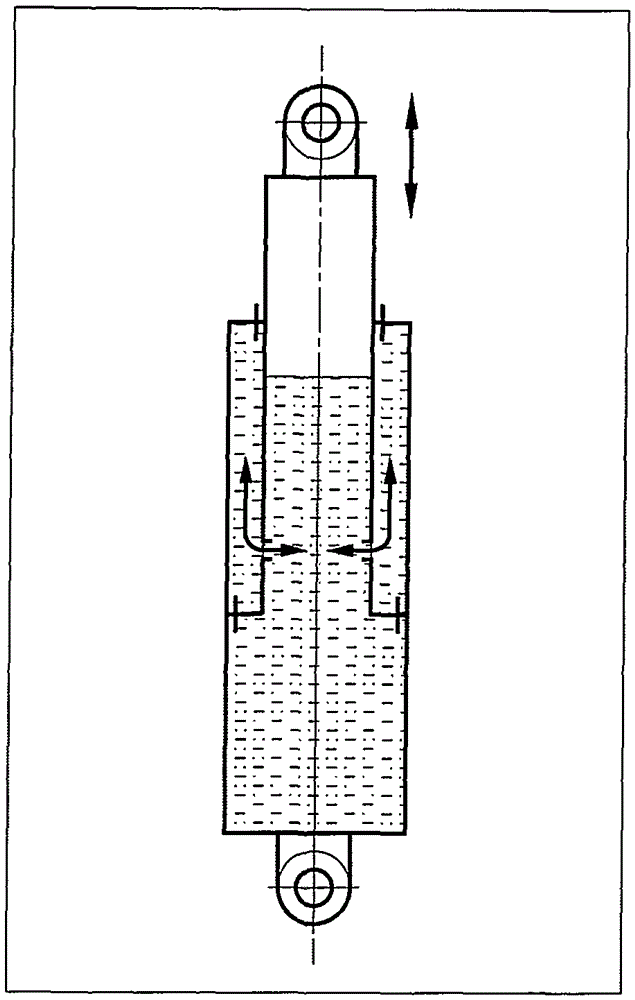

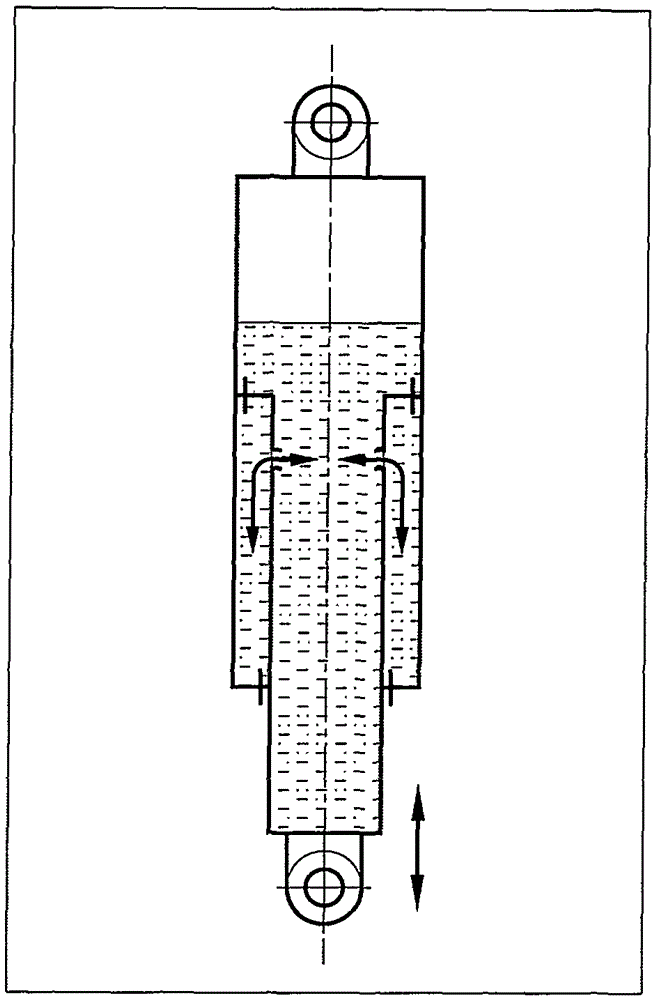

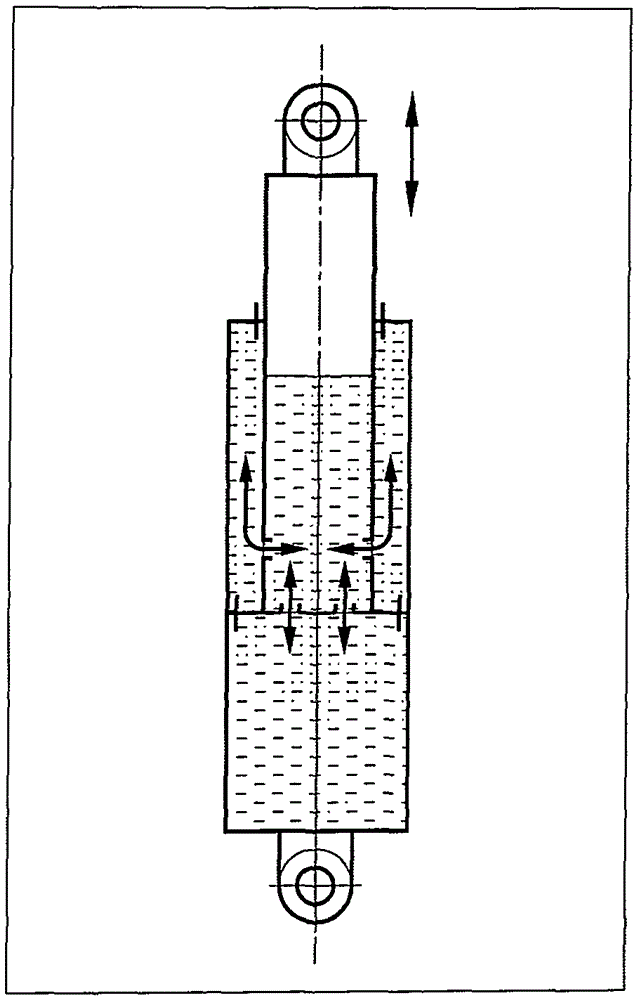

[0100] In this patent, an externally controlled isolated double-chamber oil-gas suspension cylinder includes a piston rod 10, a piston 11, an internal control valve group 12, a cylinder barrel 13, a sealing seat ring 14, an accumulator 15, a control valve 16, and a pipeline 17. The cylinder 13, the piston rod 10 and the piston 11 enclose a suspension cylinder inner cavity 20 (rodless cavity) inside the suspension cylinder. Described cylinder barrel 13, seal seat ring 14 and piston rod 10, piston 11 encircle auxiliary oil chamber 21 (rod chamber) between the side walls of the waist of the suspension cylinder. The auxiliary oil chamber 21 is filled with hydraulic oil and is completely isolated from the inner chamber 20 of the suspension cylinder. The suspension cylinder inner cavity 20 is divided into a cylinder inner cavity 22 and a piston rod inner cavity 23 by an internal control valve group 12 at the bottom of the piston rod 10 . The inner chamber of the cylinder barrel 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com