A waste heat boiler for powder ore suspension magnetization roasting powder rapid cooling and cooling process

A technology of magnetization roasting and waste heat boiler, applied in the field of energy saving and metallurgy, which can solve the problems of energy waste, large wear and tear of heat exchange equipment, and reduced energy utilization efficiency, so as to reduce production costs, reduce energy consumption of enterprises, and increase economic benefits of enterprises Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

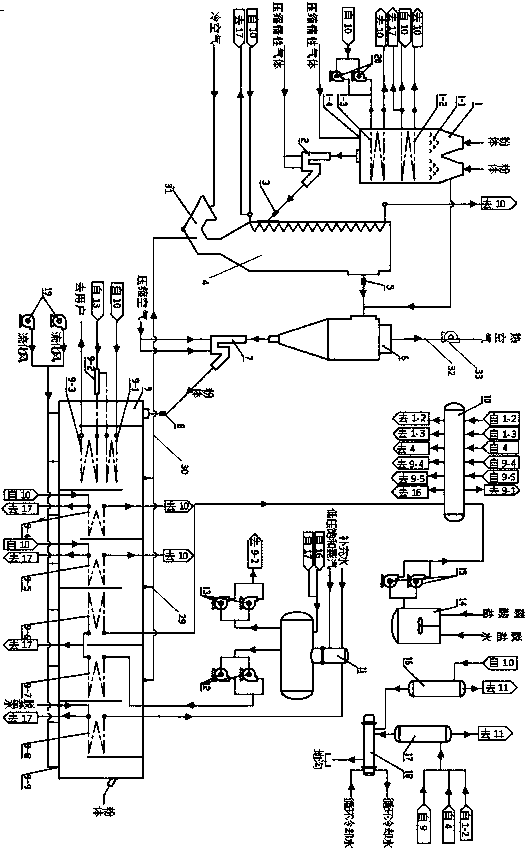

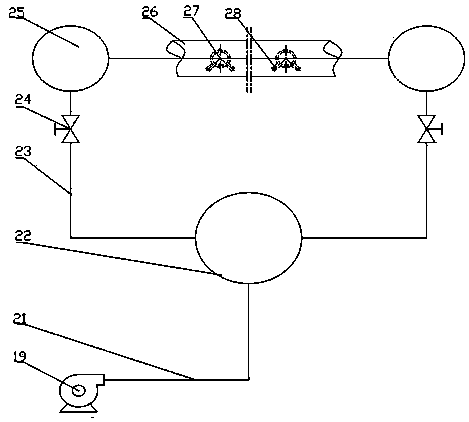

[0025] The present invention will be further described below in conjunction with the accompanying drawings. The boiler includes a pre-evaporator (1), an airlock I (2), a suspended bed evaporator (4), a cyclone separator (6), an airlock II (7 ), fluidized bed heat exchanger (9), steam drum (10), deaerator (11), dosing device (14) and sewage system. The blowdown system includes a continuous blowdown expander (16), a regular blowdown expander (17) and a blowdown heat exchanger (18). The continuous blowdown expander (16) and the regular blowdown expander (17) exchange heat with the blowdown through blowdown pipes respectively Device (18) is connected. The front evaporator (1) includes a distributor (1-1), a natural circulation evaporation heating surface (1-2), a forced circulation evaporation heating surface (1-3) and a fluidizing wind device Ⅰ (1-4). The heat exchange tubes of the circulation evaporation heating surface (1-2) and the forced circulation evaporation heating surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com