Material formaldehyde emission rate limit load rate test method

A test method and technology of load-carrying rate, applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve the problems of reducing indoor environmental quality, expensive test equipment, complex models, etc., to avoid disturbed airflow errors, shorten test cycles, and experimental time. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

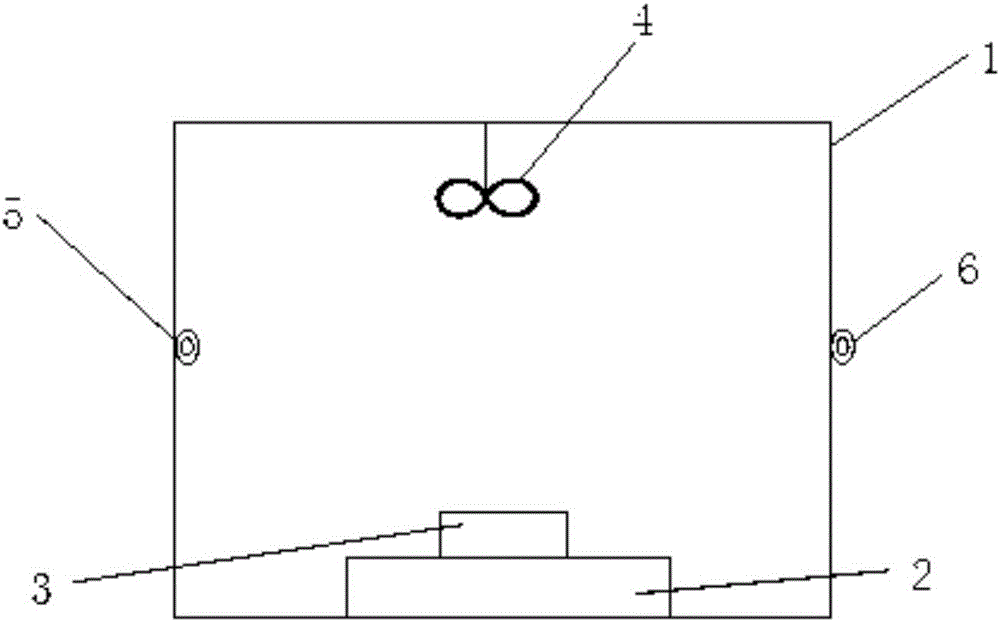

[0041] An embodiment of the present invention proposes a method for testing the ultimate load-carrying rate of formaldehyde emission rate of man-made board materials, the steps of which include:

[0042] 1) Clean the test chamber and place it in a clean environment to dry to ensure that the background concentration of formaldehyde in the test chamber is less than or equal to 0.006mg / m 3 ; Assemble the components of the test chamber, place the test chamber in a constant temperature and humidity environment; determine the ultimate load-bearing rate of the sample to 0.25m 2 / m 3 .

[0043] 2) Cut the man-made board into the required experimental size, perform balance treatment, place it on the sample holder of the test chamber, with the test surface facing the middle of the test chamber, seal the test chamber, and record it as the zero point of the experiment;

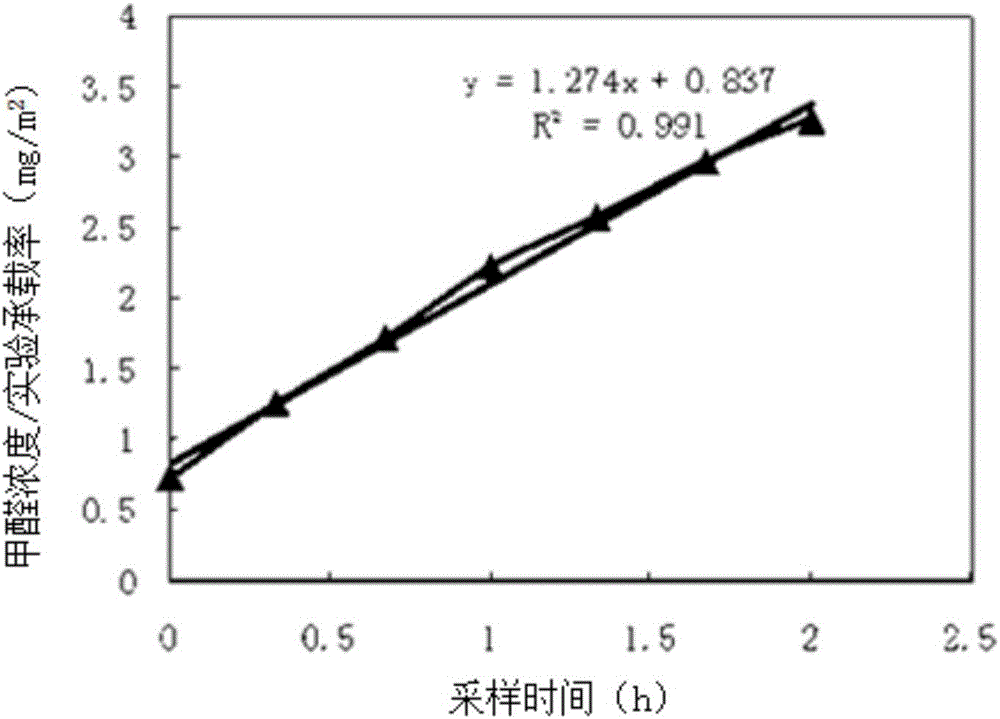

[0044] 3) Collect the gas in the test chamber, test the formaldehyde concentration in the test chamber and record the...

Embodiment 2

[0047] One embodiment of the present invention proposes a method for testing the ultimate bearing capacity of the formaldehyde emission rate of the adhesive material, the steps of which include:

[0048] 1) Clean the test chamber and place it in a clean environment to dry to ensure that the background concentration of formaldehyde in the test chamber is less than or equal to 0.006mg / m 3 ; Assemble the components of the test chamber, place the test chamber in a constant temperature and humidity environment; determine the ultimate load-bearing rate of the sample to 0.25m 2 / m 3 .

[0049] 2) Brush the adhesive on a glass plate or a stainless steel plate to make the size required for the experiment, dry it, place it on the sample holder of the test chamber, with the test surface facing the middle of the test chamber, seal the test chamber, and record it as the zero point of the experiment;

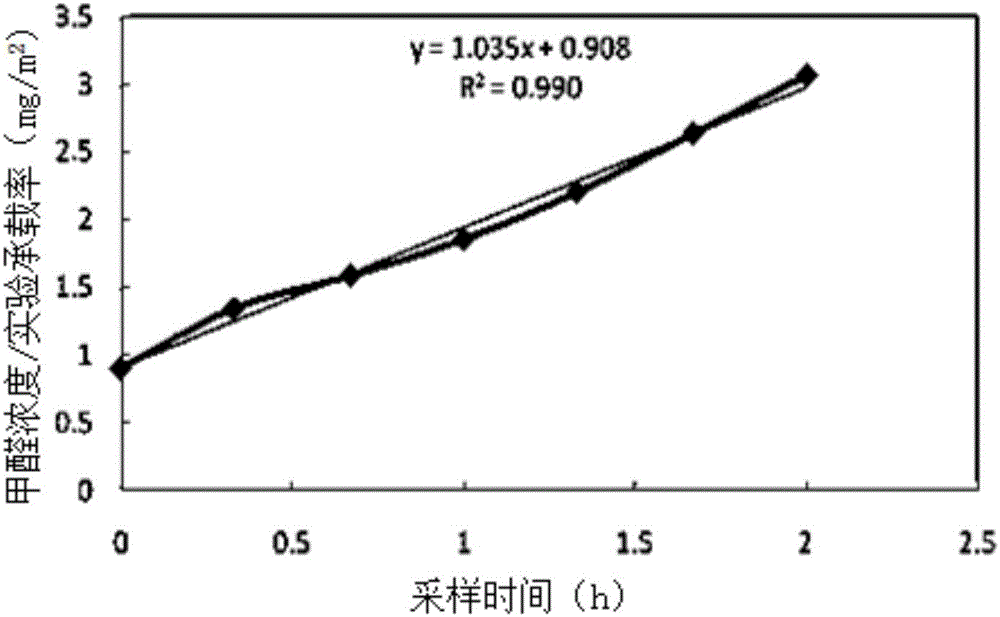

[0050] 3) Collect the gas in the test chamber, test the formaldehyde concentration in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com