Flexible copper mesh-based touch screen and preparation method thereof

A technology of copper grid and touch screen, which is applied in the direction of instruments, electrical digital data processing, and input/output process of data processing, etc. It can solve the problems of high reflectivity, increased cost of touch screen, and increased weight of touch screen, etc., and achieve high transmittance , the effect of strong environmental resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

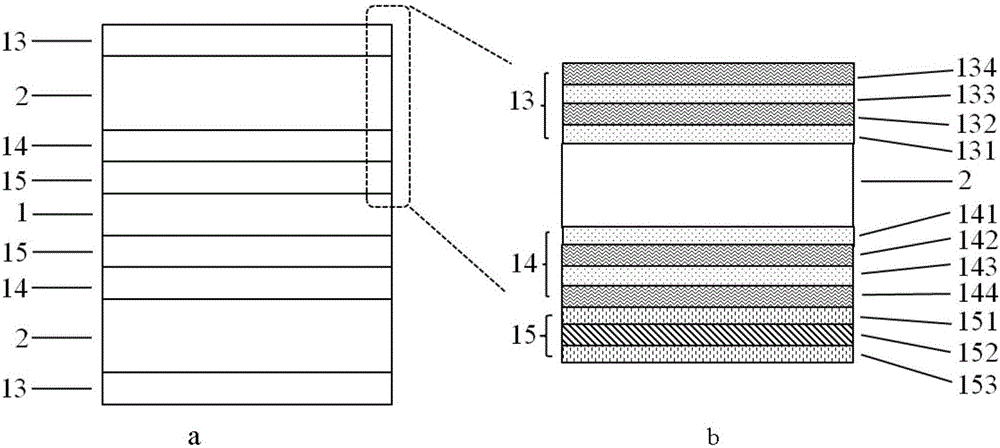

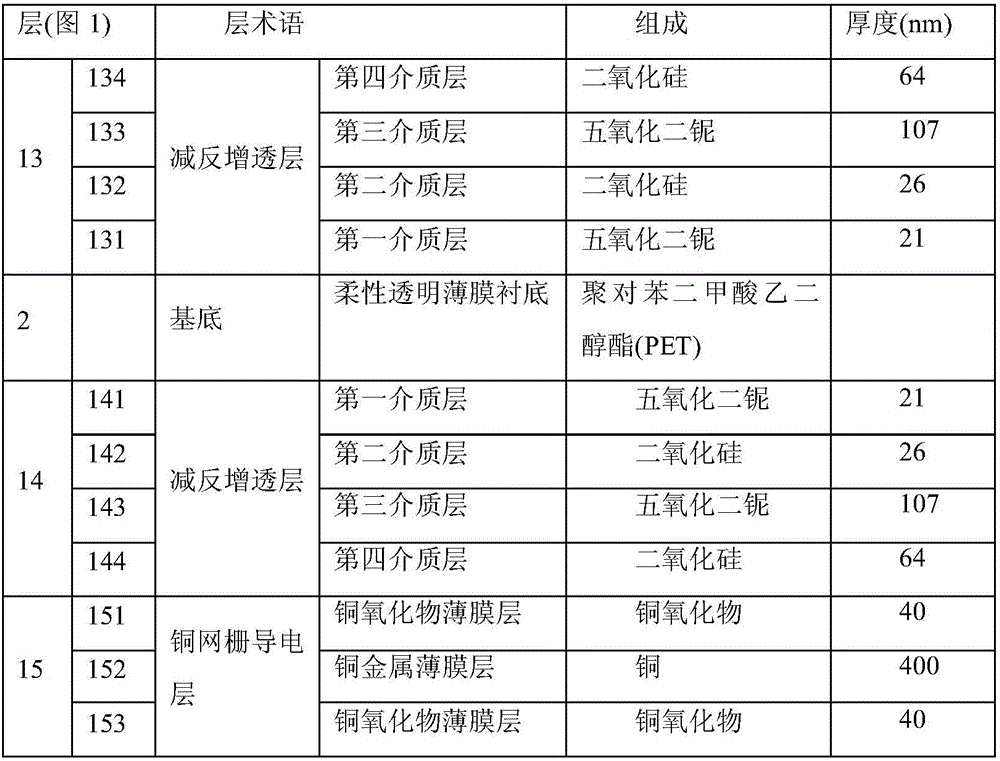

[0027] like figure 1 As shown, the figure shows an embodiment of a flexible copper grid-based touch screen, the composite film includes optical glue 1, flexible transparent polyethylene terephthalate PET substrate film 2, anti-reflection and anti-reflection layers 13 and 14 and copper grid conductive layer 15.

[0028]The transparent film substrate 2 is composed of flexible transparent polyethylene terephthalate and its double-sided UV-cured polyacrylate hard coating. Preferably, the thickness of the flexible transparent substrate 2 is 50 microns, and may also be 125 microns. The UV-cured polyacrylate hardening coating is evenly coated on both sides of the flexible transparent PET substrate by a traditional roll-to-roll coating method, so as to improve the strength, hardness and durability of the flexible transparent substrate 2 .

[0029] The anti-reflection and anti-reflection layers 13 and 14 are multi-layer stacked structures covering the upper and lower surfaces of the ...

Embodiment 2

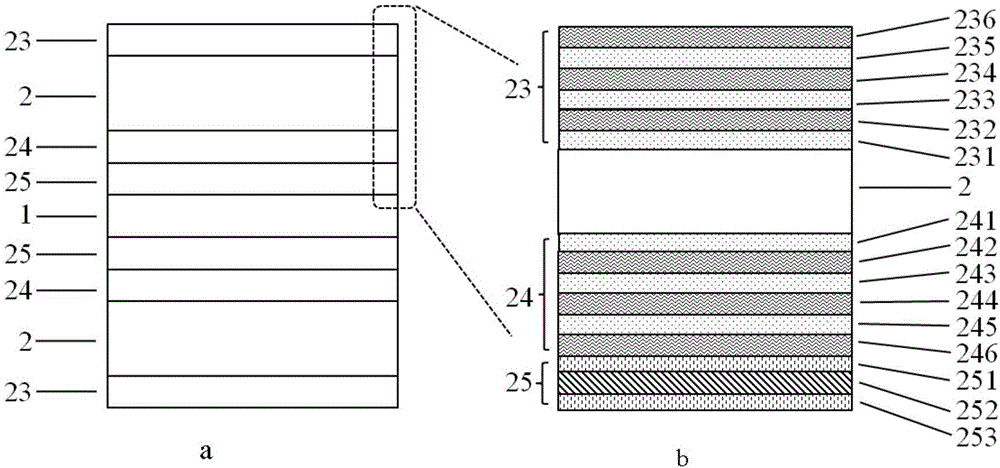

[0035] like figure 2 As shown, this figure shows an embodiment of a flexible copper grid base touch screen, and the composite film includes optical glue 1, flexible transparent polyethylene terephthalate PET substrate film 2, anti-reflection and anti-reflection layers 23 and 24 and copper grid conductive layer 25.

[0036] The transparent film substrate 2 is composed of flexible transparent polyethylene terephthalate and its double-sided UV-cured polyacrylate hard coating. Preferably, the thickness of the flexible transparent substrate 2 is 50 microns, and may also be 125 microns. The UV-cured polyacrylate hardening coating is evenly coated on both sides of the flexible transparent PET substrate by a traditional roll-to-roll coating method, so as to improve the strength, hardness and durability of the flexible transparent substrate 2 .

[0037] The anti-reflection and anti-reflection layers (23 and 24) are multi-layer stacked structures, covering the upper and lower surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com