Soft cable used for industrial robot

一种工业机器人、柔软的技术,应用在绝缘电缆、可弯曲的电缆、可延伸的导体电缆等方向,能够解决钢丝断裂、起不到承重和抗拉作用、绝缘或护套扎破等问题,达到减少静电的产生、结构变化影响低、减少摩擦力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

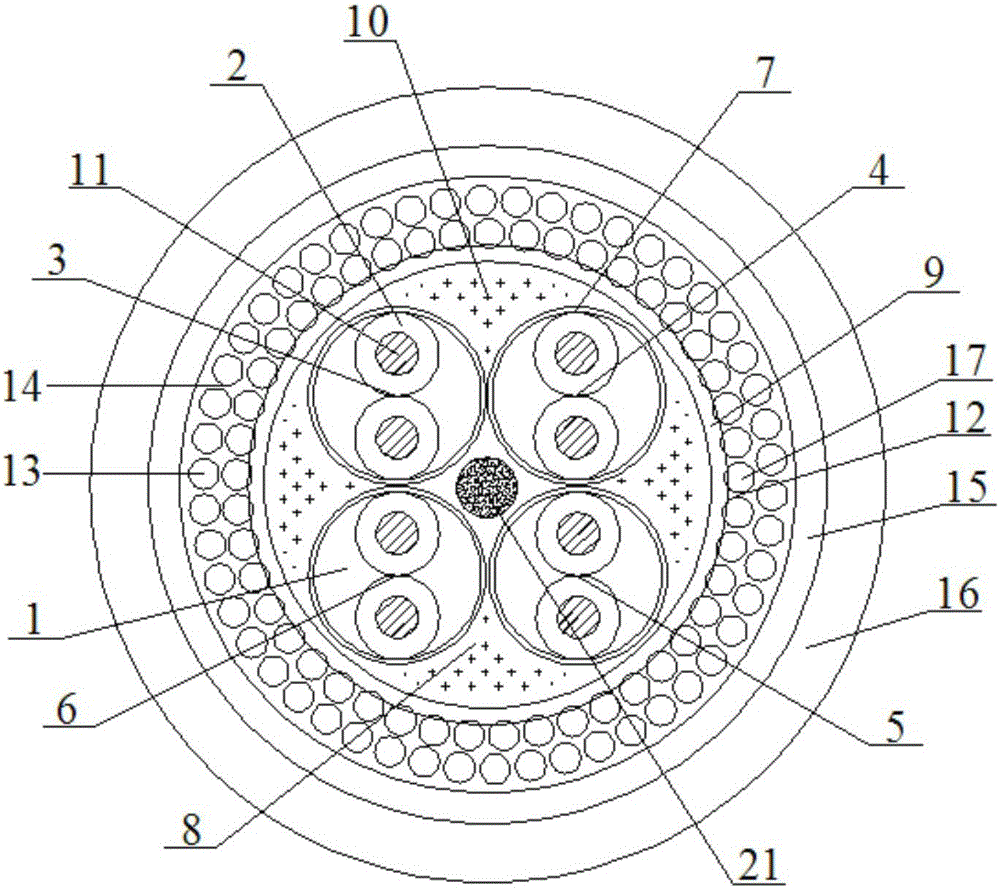

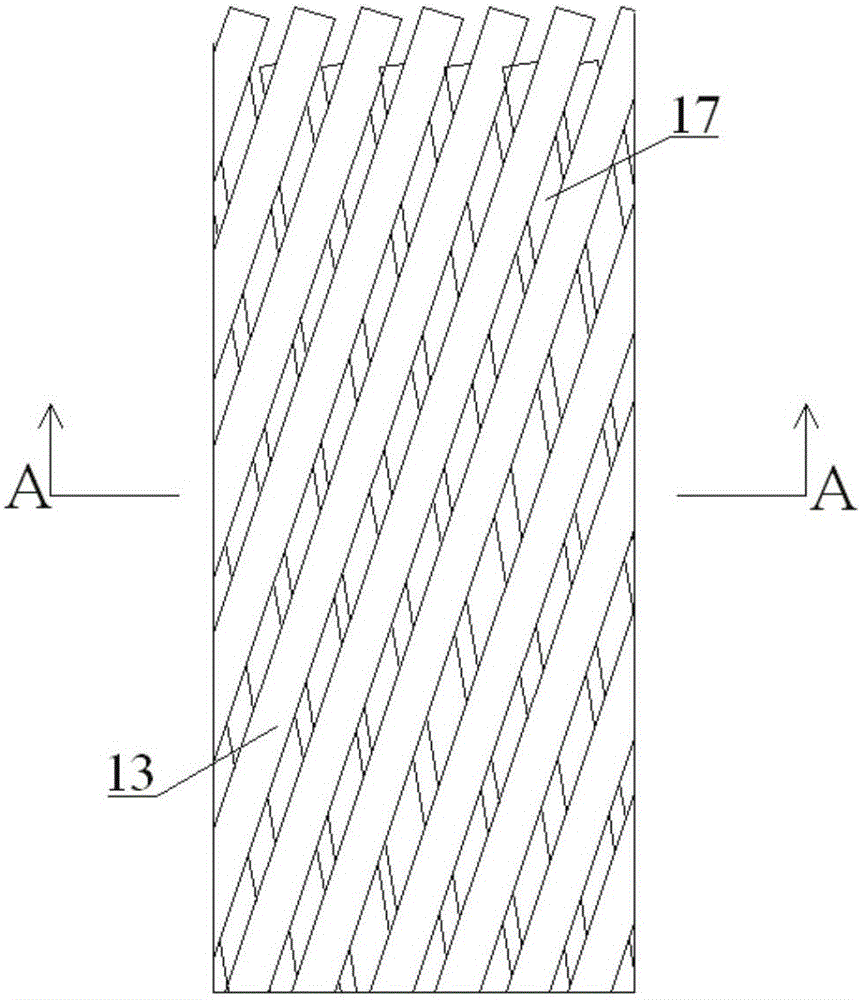

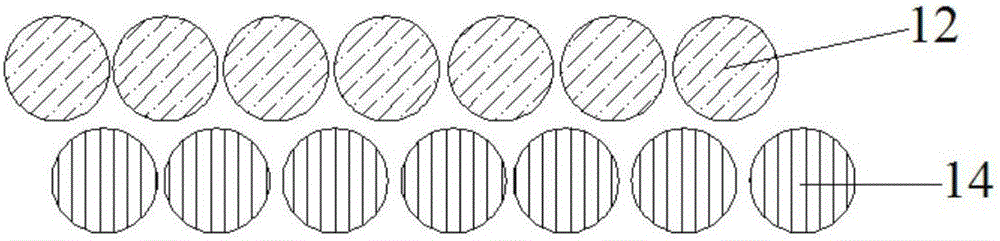

[0027]Embodiment: A flexible cable for industrial robots, including: eight metal conductor units 1 and aramid fiber reinforcements 21, the outer surface of the metal conductor units 1 is covered with an insulating polypropylene layer 2, and the metal conductor units 1 include The aramid fiber 20 at the center, the inner conductive layer composed of several first tin-copper alloy conductors 22 twisted on the outer surface of the aramid fiber 20, the first oxygen-free copper conductor 23, and the inner conductive layer composed of several second tin-copper alloy conductors The conductor 24 and the second oxygen-free copper conductor 25 are stranded on the outer surface of the inner conductive layer to form an outer conductor layer. The diameters of the first tin-copper alloy conductor 22 and the first oxygen-free copper conductor 23 are equal, and the second tin-copper alloy conductor The conductor 24 and the second oxygen-free copper conductor 25 have the same diameter, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dynamic friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com