A kind of fp chip shaping device and shaping method

A shaping device and chip technology, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve the problems of thin and fragile pins, affecting welding quality, and affecting the coplanar shape of chip pins, so as to ensure the forming quality, Effect of reducing welding defects and improving solderability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

[0020] At present, the plastic processing of FP chips before packaging is mostly manual single processing. Due to the large number of pins of the FP chip itself, the pins are thin and fragile, and the body is difficult to clamp, the current manual single processing is time-consuming, laborious, and inefficient. The pass rate is high. In order to solve the above problems, the present invention proposes a convenient, safe and reliable FP chip shaping device. At the same time, the invention also provides an FP chip shaping method.

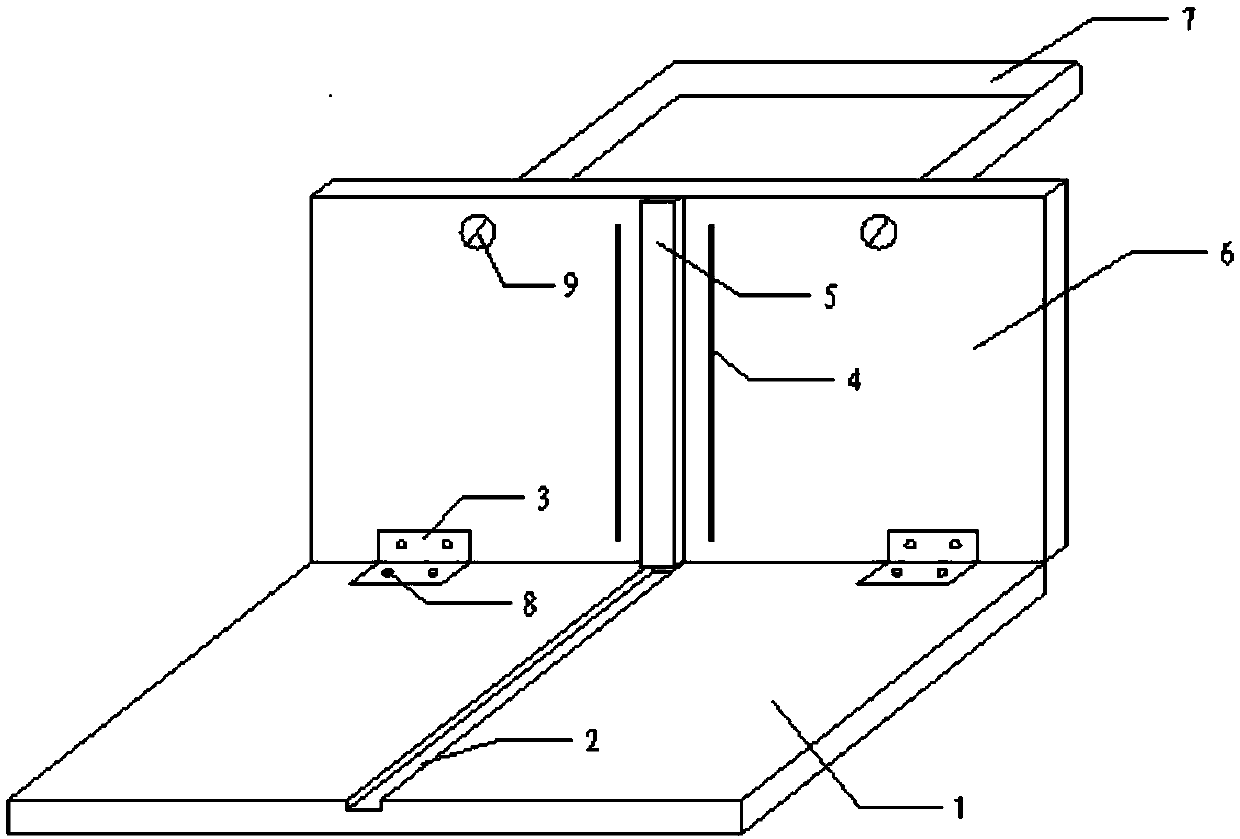

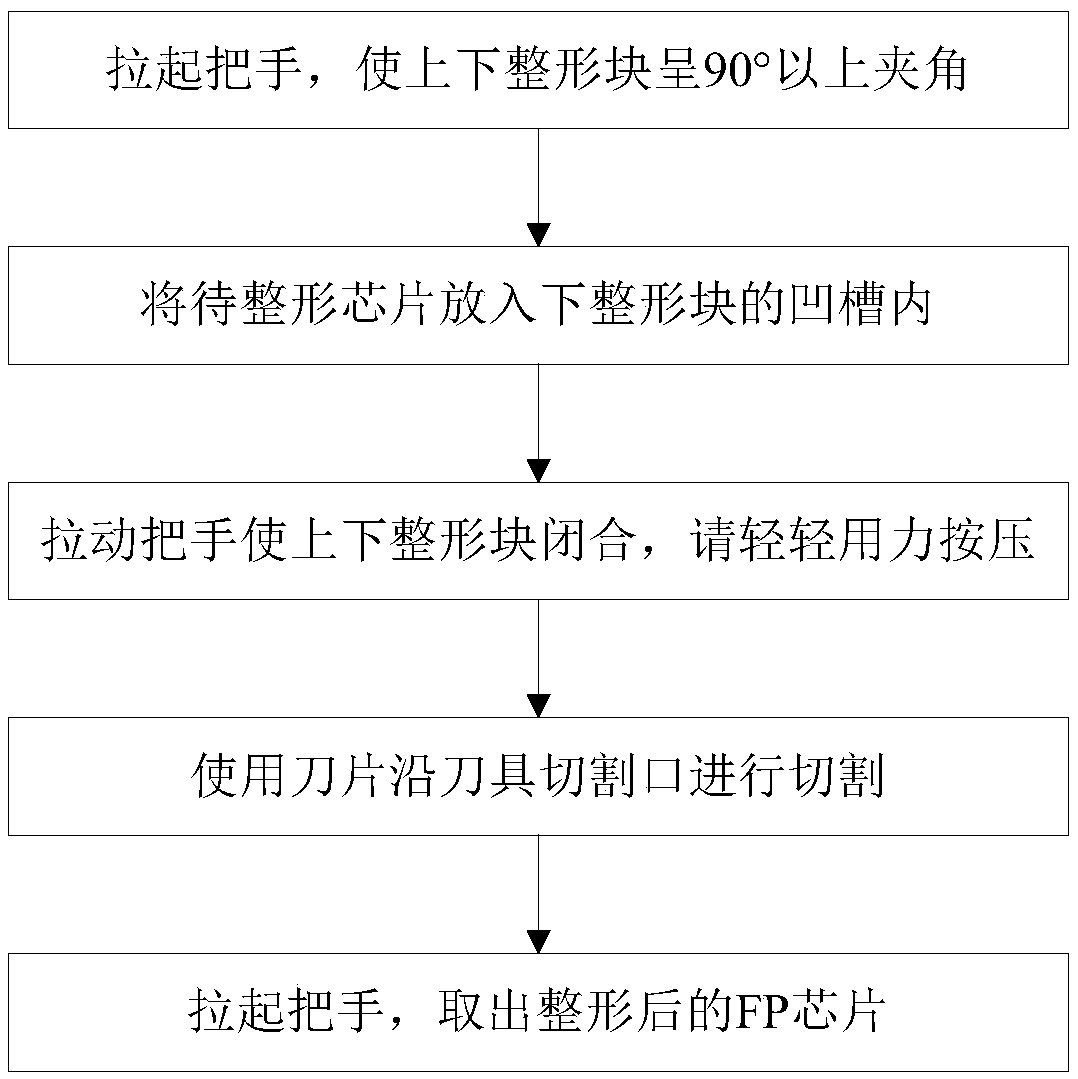

[0021] Such as figure 1 As shown, the FP chip shaping device includes a lower shaping block 1 and an upper shaping block 6; the lower shaping block 1 and the upper shaping block 6 are hinged through a hinge structure 3; the lower sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com