Preparation method of NiS2 catalyst with high specific surface area

A technology with high specific surface area and specific surface area, used in electrochemical generators, fuel cells, electrical components, etc., can solve problems such as high price, large-scale commercial application constraints, and reduced catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

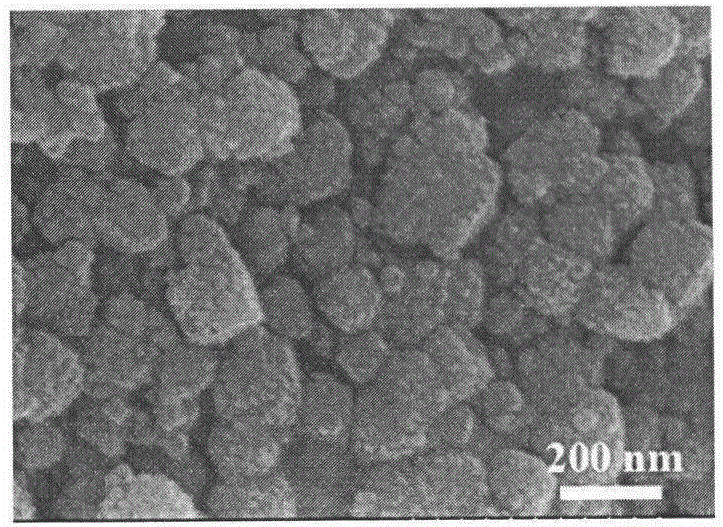

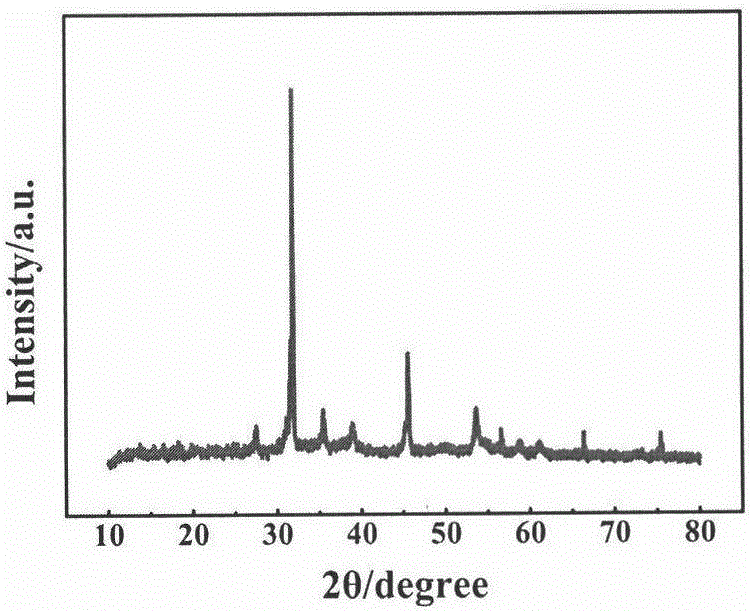

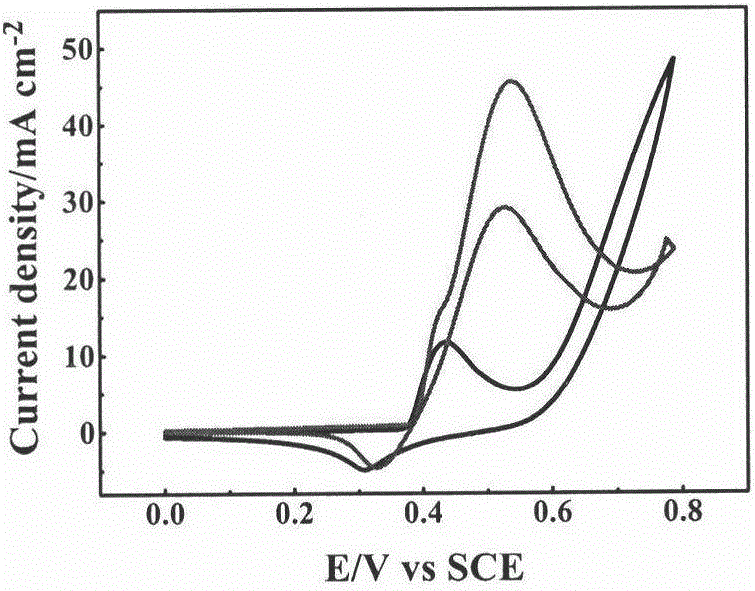

[0013] A NiS with high specific surface area 2 The preparation method of the catalyst comprises the following steps: respectively placing 1.6g of sodium sulfide, 0.7g of nickel chloride and 70ml of water in a 100ml beaker, and adjusting the pH to 4, stirring for 2h, and then carrying out hydrothermal heating at a temperature of 120°C. Keep the hydrothermal time for 10 hours, filter the hydrothermal sample, then put it into distilled water to boil, filter and wash until neutral, dry at 60°C for 10 hours to obtain NiS with high specific surface area 2 catalyst. figure 1 In order to prepare NiS with high specific surface area 2 SEM image of the catalyst. It is obvious from the figure that the nanospheres are piled up by small particles, and the dispersion is relatively uniform. figure 2 is the XRD pattern of the catalyst. In the analysis of the XRD pattern, the peaks at 31.5°, 35.3°, 38.8°, 45.1° and 53.5° correspond to NiS 2 (200), (210), (211), (220) and (311) crystal fac...

Embodiment 2

[0015] A NiS with high specific surface area 2 The preparation method of the catalyst comprises the following steps: respectively placing 1.6g of sodium sulfide, 0.7g of nickel chloride and 70ml of water in a 100ml beaker, and adjusting the pH to 5, stirring for 2h, and then carrying out hydrothermal treatment, the hydrothermal temperature being 120°C, Keep the hydrothermal time for 10 hours, filter the hydrothermal sample, then put it into distilled water to boil, filter and wash until neutral, dry at 60°C for 10 hours to obtain NiS with high specific surface area 2 catalyst. With respect to the example 1 of the catalyst prepared by this method, the particle agglomeration is relatively severe, and the distribution is uneven, and the current density (37mA cm -2 ) and specific surface area (130.2m 2 g -1 ) decreased significantly, and its electrocatalytic performance was not particularly good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com