Automatic correction device and automatic correction method for component position of placement machine feeder

A component position and feeder technology, which is applied in the direction of assembling printed circuits with electric components, can solve the problems of low precision and achieve the effects of high correction precision, fast identification and processing speed, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

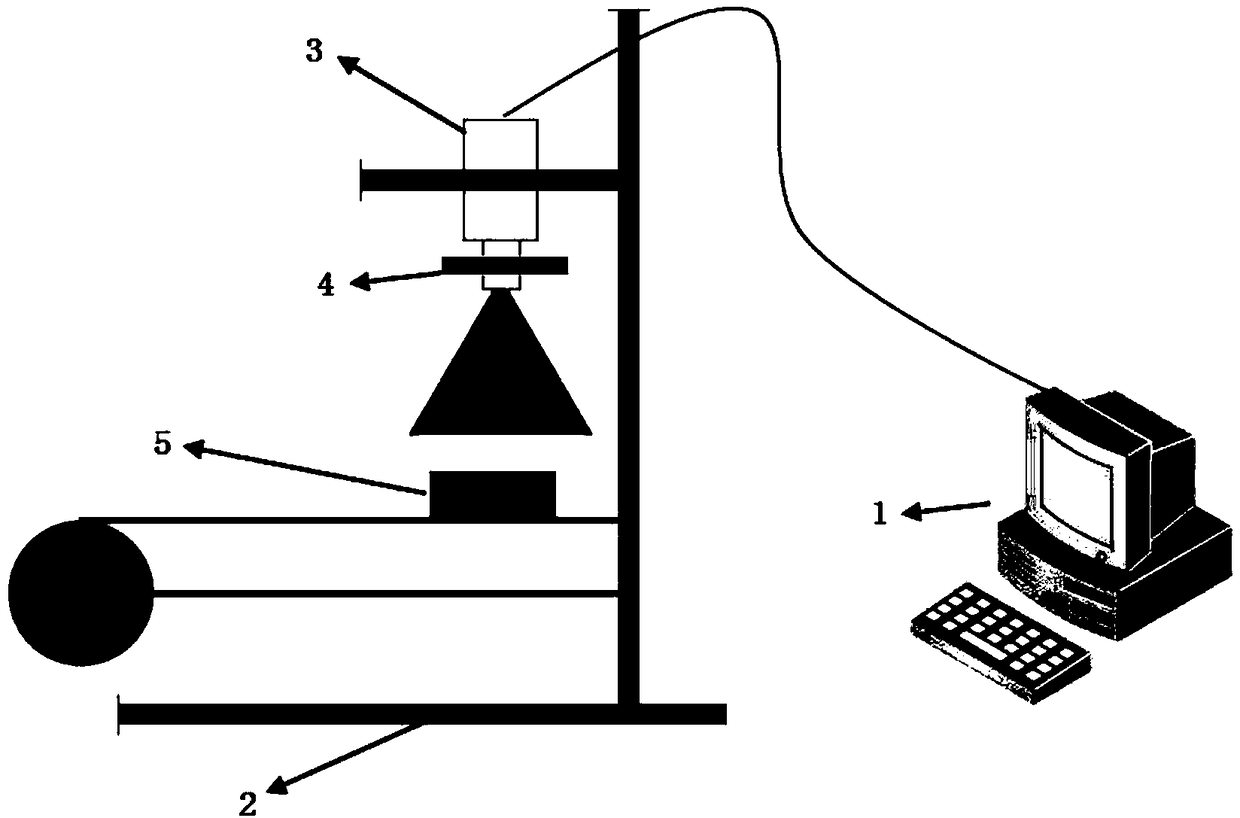

[0071] Specific implementation mode one: combine figure 1 To describe this embodiment,

[0072] An image processing-based device for automatically correcting the position of feeder components of a placement machine, comprising a host computer 1, a correction fixture 2, an industrial camera 3 and an LED light source 4; the host computer 1 is connected to the industrial camera 3; the industrial camera 3 and the feeder The feeder is fixed on the straightening fixture 2, the outlet of the feeder is aligned with the component conveyor belt, the industrial camera 3 is aligned with the outlet of the feeder and in front of the outlet, and the industrial camera 3 is used to collect the components 5 at the outlet of the feeder in real time The position image of the LED light source 4 is an adjustable light source, located at the camera head of the industrial camera 3, and the LED light source 4 is used to adjust the intensity of light in the lighting environment;

[0073] The upper com...

specific Embodiment approach 2

[0074] The control system for automatically correcting the component position of the chip mounter feeder built in the host computer described in this embodiment includes:

[0075] Communication module, used to select the correct serial port to communicate with the mounter feeder;

[0076] The display module is used to display images and prompt information; the display module includes an image display sub-module and an information prompt sub-module; wherein,

[0077] The image display sub-module is used to display the image collected by the camera in the image display window in real time;

[0078] The information prompt sub-module is used to display operation and warning prompt information;

[0079] The operation module is used to control the camera, the collected images, and correction commands and data; the operation module includes a camera control submodule, an image operation submodule, a correction command sending submodule and a data storage submodule; wherein,

[0080...

specific Embodiment approach 3

[0085] The information prompt sub-module described in this embodiment includes:

[0086] An operation information prompt unit is used to display each operation information of the operator in the operation information prompt area in real time;

[0087] The warning information prompting unit is used to prompt the user's attention and misoperation by popping up a warning information dialog box.

[0088] Other system modules and structures are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com