Detection method for bamboo shoots

A detection method and technology of bamboo shoots, which are applied in measurement devices, material analysis using wave/particle radiation, instruments, etc., can solve the problems of complicated steps, complete detection accuracy, long detection period, etc., and achieve the improvement of metal element content and strength. and the effect of compressed density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

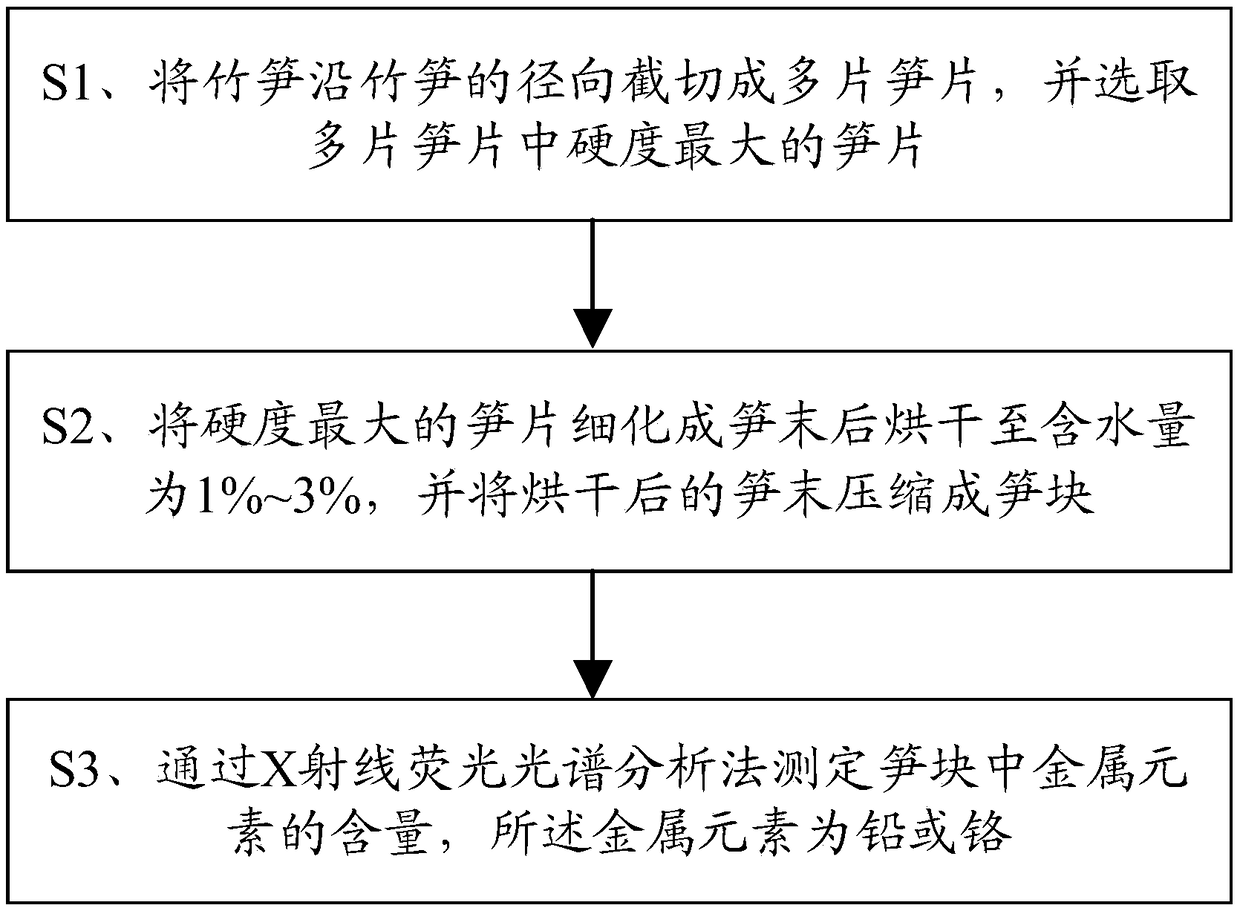

[0048] Please refer to figure 1 Shown, embodiment one of the present invention is:

[0049] A detection method for bamboo shoots, comprising the following steps:

[0050] S1. Detect bamboo shoots whose content of metal elements exceeds the content set value in the metal detector through a metal detector, cut the detected bamboo shoots into multiple bamboo shoots along the radial direction of the bamboo shoots, and select multiple bamboo shoots The hardest bamboo shoots among the slices;

[0051] Wherein, cutting the bamboo shoots whose metal element content exceeds the content setting value along the radial direction of the bamboo shoots into multiple bamboo shoots is specifically: cutting the bamboo shoots along the radial direction of the bamboo shoots into slices with a cutter made of ceramic material or polymer material. A plurality of bamboo shoots, and a pressure sensor is set on the cutter;

[0052] S2, thinning the bamboo shoots with the highest hardness into minced...

Embodiment 2

[0061] A detection method for bamboo shoots, the difference from Example 1 is: the bamboo shoots with the highest hardness are thinned into bamboo shoots and then dried until the water content is 2%, and the dried bamboo shoots are used by non-metal molds The pressure of 105MPa is compressed into bamboo shoots.

Embodiment 3

[0063] A detection method for bamboo shoots, which differs from Example 1 in that: the bamboo shoots with the highest hardness are thinned into powdered bamboo shoots and then dried to a moisture content of 3%, and the dried bamboo shoots are used as The pressure of 90MPa is compressed into bamboo shoots.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com