Method for adjusting concentration of cooling water treatment agent in circulating cooling water system, method for recovering discharged cooling water, and treatment device for discharged cooling water

A technology of cooling water treatment and circulating cooling water, applied in water/sludge/sewage treatment, osmosis/dialysis water/sewage treatment, sterilization/microdynamic water/sewage treatment, etc., can solve the problems of increasing treatment costs, Achieve stable operation and reduce water treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0112] The following examples are given to illustrate the present invention more specifically, but the present invention is not limited to the following examples unless the gist is exceeded.

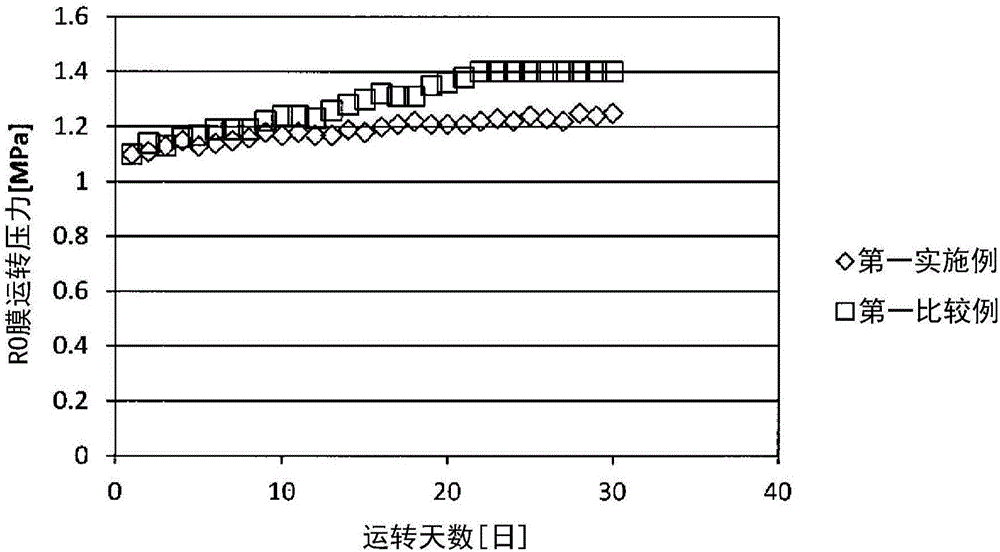

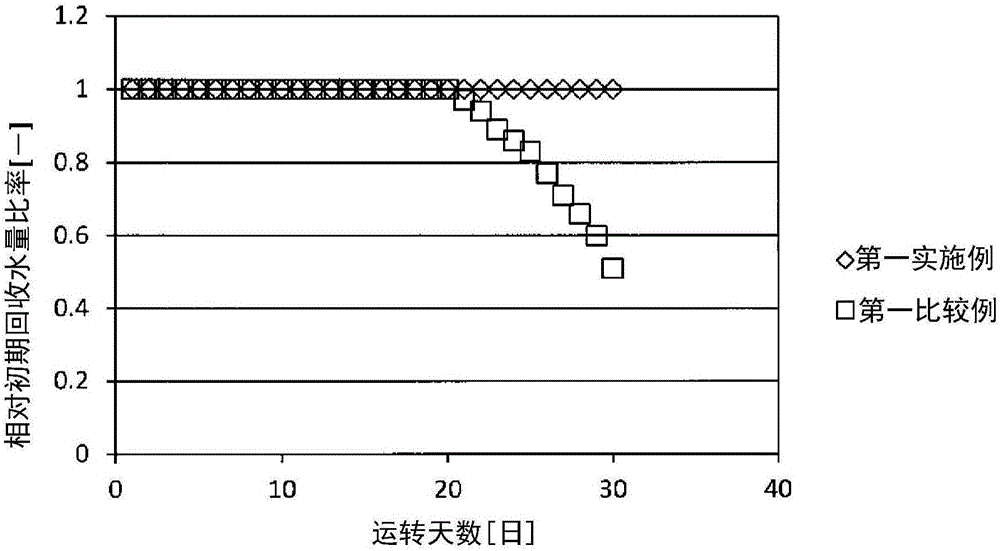

no. 1 example

[0114] Chiba industrial water is used as raw water, and the cooling tower discharge water (hereinafter referred to as "discharge water") of the circulating cooling water system operating at a concentration ratio of 3.5 times is treated in the order of coarse filter, MF membrane device, and RO membrane device Water recovery is carried out, and the recovered water is returned to the circulating cooling water system.

[0115] In this circulating cooling water system, as a scale dispersant, a copolymer of acrylic acid and AMPM (acrylic acid:AMPM (molar ratio) = 70:30, weight average molecular weight 10,000, hereinafter referred to as "AA / AMPS") is added to make the system The internal maintenance concentration is 3mg / L, and simultaneously as a slime control agent, according to the method of the first embodiment of the International Publication WO2011 / 125762 bulletin, add the combined chlorine agent prepared using sodium hydroxide, sulfamic acid and sodium hypochlorite, so that The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com