Systems and methods for multiple-beam laser arrangements with variable beam parameter product

A parameter adjustment system and beam technology, applied in the field of laser systems, can solve problems such as time-consuming and damage to optical components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

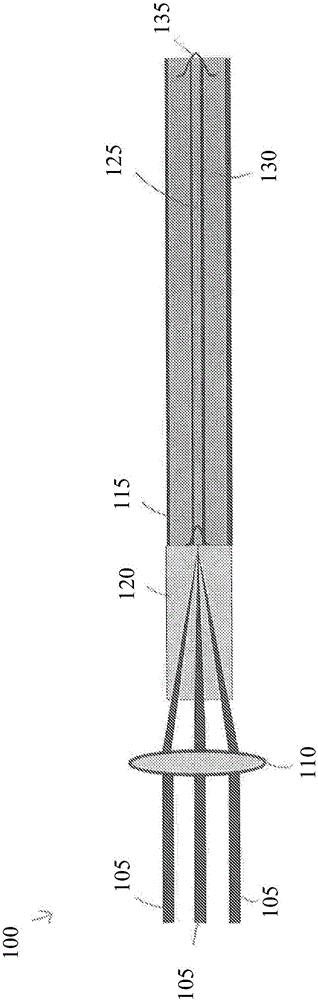

[0048] figure 1is a schematic diagram of a laser system 100 according to various embodiments of the invention. In the laser system 100 , one or more input beams 105 are focused by a focusing lens 110 into an optical fiber 115 having a fiber end cap 120 . End cap 120 may be, for example, a sheet of coreless (i.e., substantially uniform) or gradient index (i.e., having a graded index of refraction) glass, and end cap 120 may advantageously reduce the light at the glass-air interface for a given optical power. Strong and / or protected optical fiber 115 from environmental damage (eg, moisture). As shown, optical fiber 115 may have one or more cores 125 surrounded by one or more cladding layers 130 . For the laser system 100, the BPP of the input beam or beam 105 can be defined as (x / 2) x θ = (x x d) / (4 x f), where x is the diameter (or beam size) of the input beam 105, θ is the laser beam divergence (or “beam divergence”) of the input beam 105 , d is the focal diameter of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com