Salad dressing containing pea resistant starch and preparation method of salad dressing

A technology of pea resistant starch and salad dressing, which is applied to the functions of food ingredients, food ingredients as taste improvers, and food ingredients as taste improvers, etc. It can solve the problem of stratification, easy oil separation, and influence on product flavor and shelf life. period and other problems, to achieve the effect of low cost, less nutrient loss, relief and treatment of constipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] As a preferred embodiment of this patent, the salad dressing containing pea resistant starch in this example is composed of the following raw materials in proportions by mass: egg yolk powder 7%, resistant starch 7%, rapeseed oil 35%, 5° White vinegar 7%, concentrated lemon juice 5%, salt 1%, soft white sugar 3.5%, xanthan gum 0.25%, water added to 100%.

[0020] Its preparation method is realized by following steps:

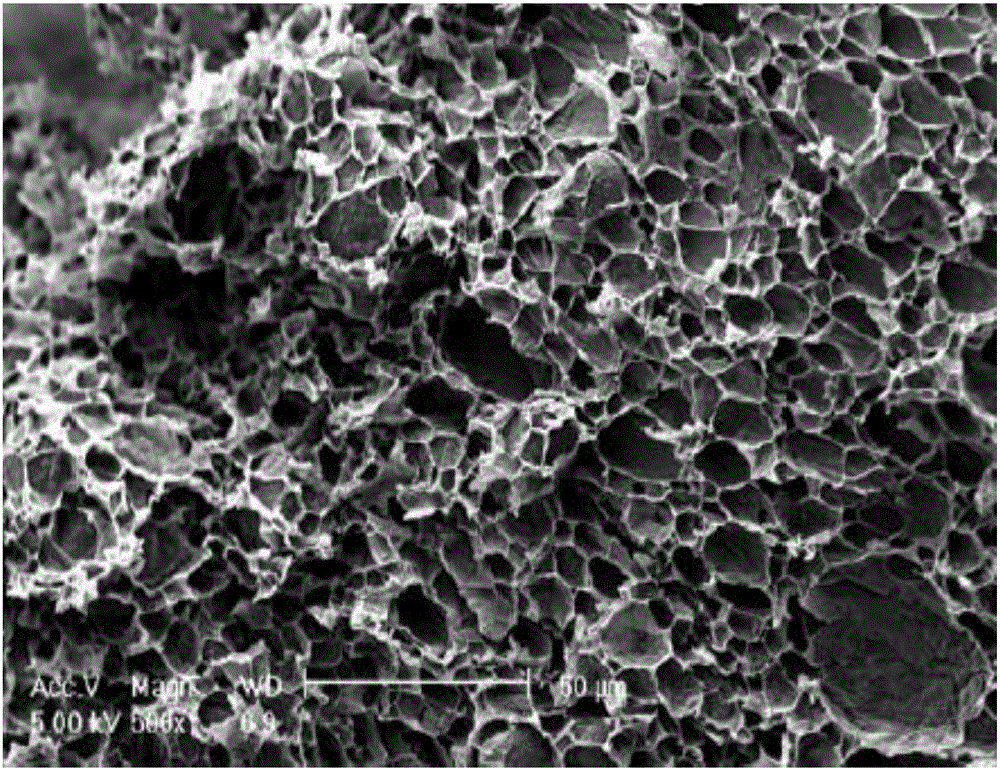

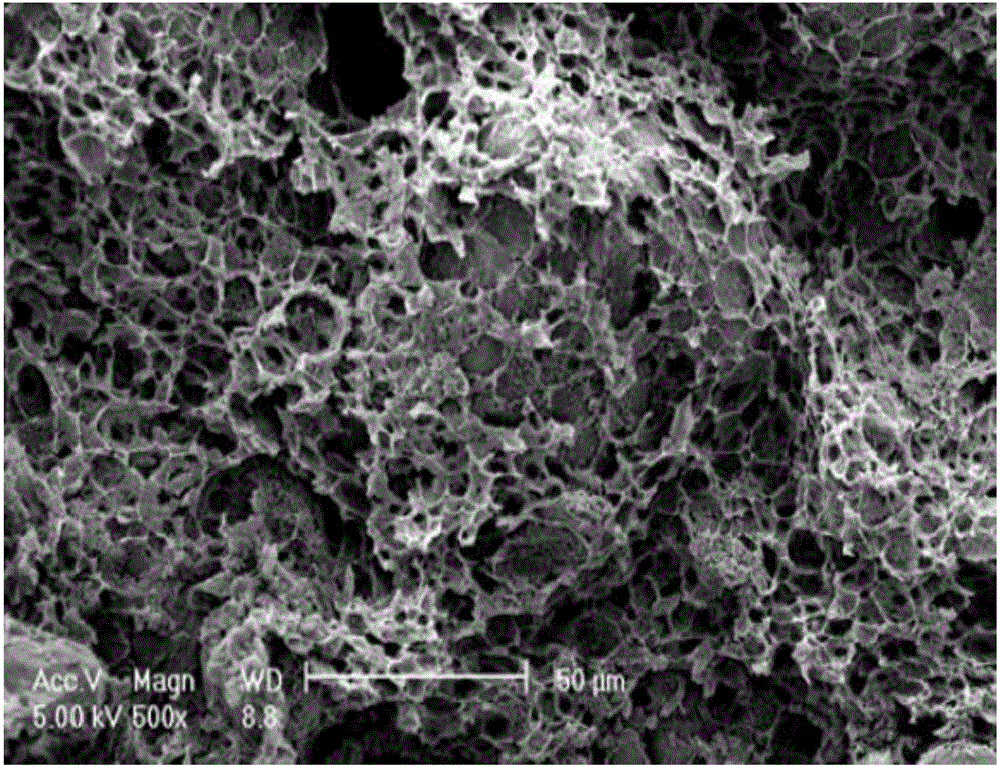

[0021] (1) Weigh pure pea starch, add distilled water, be configured into starch milk with a concentration of 30%, adjust the pH of the starch milk to 6.0 with a pH of 6.4 and a concentration of 0.1mol / L sodium citrate buffer in a boiling water bath Pre-gelatinize the above-mentioned treated starch milk for 5 minutes, put it into a high-pressure steam pot, and heat it at 121°C for 1 hour to make it completely gelatinized, take out the sample after autoclaving, and place it at room temperature to make it Natural cooling, refrigerated at 4°C for 24 hours t...

Embodiment 2

[0025] The salad dressing containing pea resistant starch in this example is composed of the following raw materials in proportion by mass: egg yolk powder 3%, resistant starch 5%, rapeseed oil 7.5%, 5° white vinegar 6%, concentrated lemon juice 4% %, salt 0.5%, soft white sugar 2.0%, xanthan gum 0.2%, water added to 100%.

[0026] Its preparation method is realized by following steps:

[0027] (1) Take pure pea starch, add distilled water, be configured into starch milk with a concentration of 20%, adjust the pH of the starch milk to 5.8 with a pH of 6.2 and a concentration of 0.1mol / L sodium citrate buffer in a boiling water bath Pre-gelatinize the above-mentioned starch milk for 4 minutes, put it into a high-pressure steam pot, and heat it at 110°C for 1.5 hours to make it completely gelatinized. After autoclaving, take out the sample and place it at room temperature to make it Natural cooling, refrigerated at 0°C for 24 hours to age the starch, repeated the above steps 3 ...

Embodiment 3

[0031] The salad dressing containing pea resistant starch in this example is composed of the following raw materials in proportion by mass: 5% egg yolk powder, 3.5% resistant starch, 15% rapeseed oil, 7% 5° white vinegar, 3% concentrated lemon juice %, salt 0.75%, soft white sugar 2.0%, xanthan gum 0.23%, water added to 100%.

[0032] Its preparation method is realized by following steps:

[0033] (1) Take pure pea starch, add distilled water, be configured into starch milk with a concentration of 30%, adjust the pH of the starch milk to 6.0 with a pH of 6.36 and a concentration of 0.1mol / L sodium citrate buffer in a boiling water bath Pre-gelatinize the above-mentioned treated starch milk for 6 minutes, put it into a high-pressure steam pot, and heat it at 125°C for 0.8 hours to make it completely gelatinized, take out the sample after autoclaving, and place it at room temperature to make it Natural cooling, refrigerated at 4°C for 18 hours to age the starch, repeated the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com