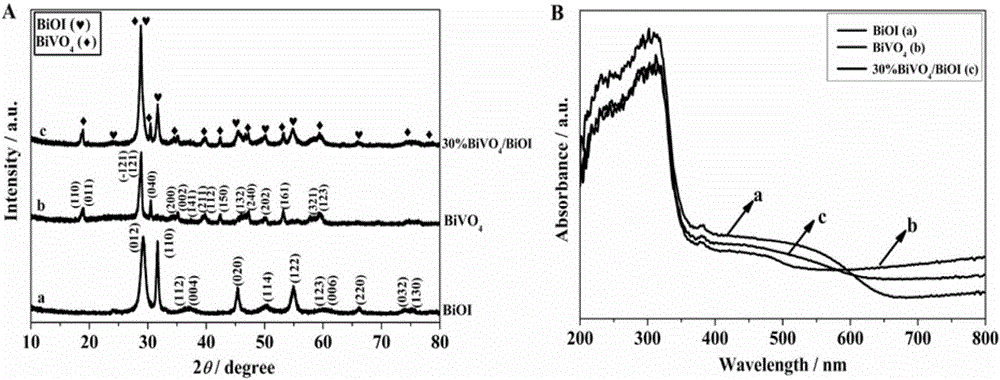

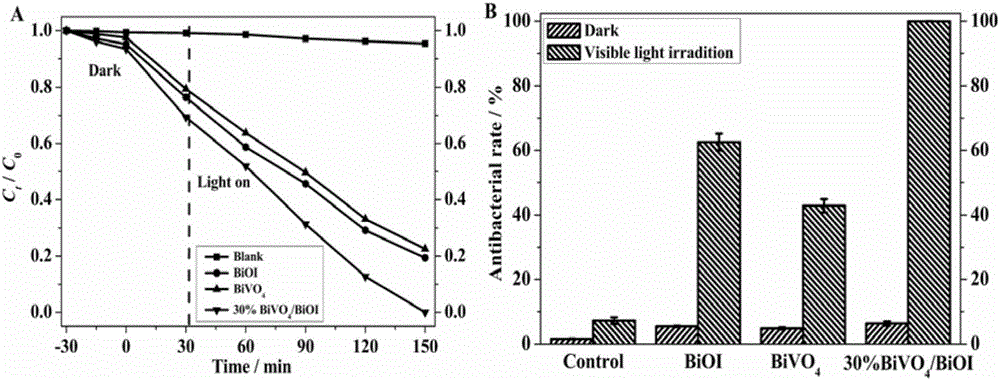

BiVO4/BiOI heterojunction compound photocatalyst and preparation method and application thereof

A technology of composite light and catalyst, applied in the field of photocatalysis, can solve the problems of limited photocatalytic performance of semiconductor materials, easy recombination of photogenerated carriers, etc., achieve good visible light absorption performance, simple preparation method and accelerated separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] BiVO 4 / BiOI heterojunction composite photocatalyst preparation method:

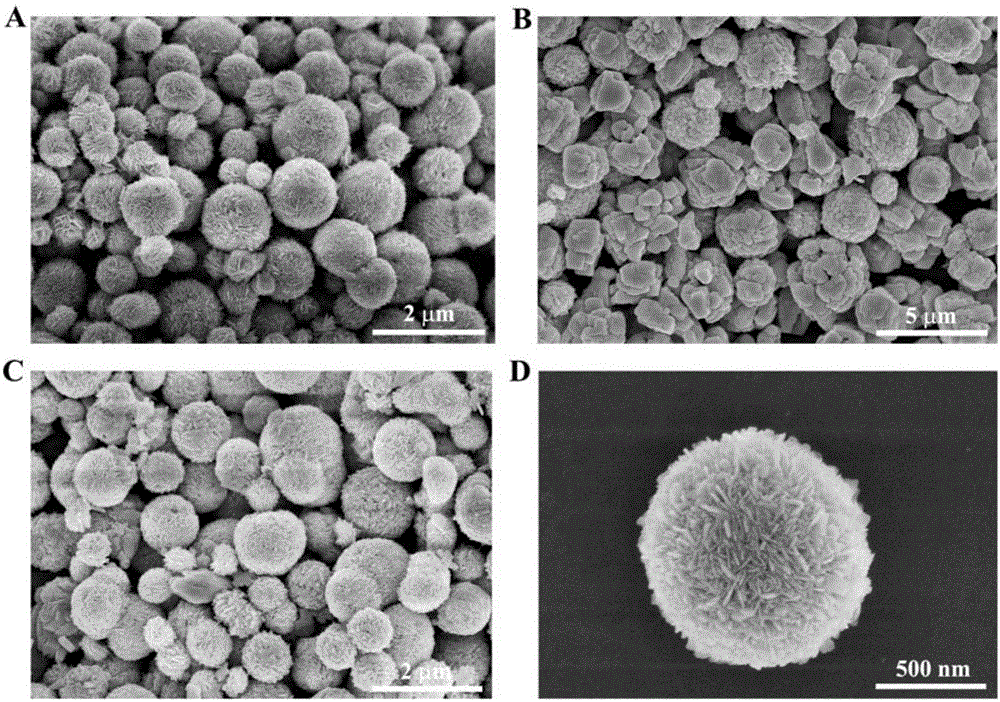

[0041] (1) Preparation of three-dimensional layered microsphere structure BiOI: prepared by hydrothermal synthesis. 2.0mmol Bi(NO 3 ) 3 ·5H 2 O was added to 30mL of ethylene glycol, and magnetically stirred to dissolve it to obtain solution A; at the same time, 2.0mmol KI and 0.5g polyvinylpyrrolidone (PVP) were added to 30mL of ultrapure water in turn, and magnetically stirred to make it Dissolve to obtain the solution B; then add the above solution B dropwise to the above solution A under magnetic stirring to obtain a suspension, then use 2.0mol / L NaOH solution to adjust the pH of the suspension to 7, and then continue the magnetic Stir for 60 minutes; after stirring, transfer the suspension to a stainless steel high-pressure reactor equipped with a polytetrafluoroethylene lining, and put it into an electric constant temperature blast drying oven for heat treatment at 180°C for 24 hours; aft...

Embodiment 2

[0049] BiVO 4 / BiOI heterojunction composite photocatalyst preparation method: prepared under hydrothermal conditions by ion exchange method, the difference from Example 1 is that the Bi 2 WO 6 The molar ratio with BiOI is 1:9. Weigh 1.0mmol BiOI obtained above and add it into 30mL ultrapure water, and ultrasonically disperse for 45min to obtain a dispersion; at the same time, add 0.1mmol NH 4 VO 4 and 0.25g polyvinylpyrrolidone (PVP) were added to 30mL ultrapure water in turn, heated to 80°C and magnetically stirred to dissolve completely to obtain a solution; then NH 4 VO 4 Dissolve the solution, and then continue magnetic stirring for 30 minutes to obtain a mixed solution; after the stirring is completed, transfer the mixed solution to a stainless steel high-pressure reactor equipped with a polytetrafluoroethylene liner, and put it in an electric constant temperature blast drying oven for heat treatment at 180°C for 16 hours After the reaction, the reactor was cooled t...

Embodiment 3

[0051] BiVO 4 / BiOI heterojunction composite photocatalyst preparation method: prepared under hydrothermal conditions by ion exchange method, the difference from Example 1 is that the Bi 2 WO 6 The molar ratio with BiOI is 5:5. Weigh the 1.0mmol BiOI obtained above and add it into 30mL ultrapure water, ultrasonically disperse for 30min to obtain a dispersion; at the same time, add 0.5mmol NH 4 VO 4 and 0.5g polyvinylpyrrolidone (PVP) were sequentially added to 30mL ultrapure water, heated to 80°C and magnetically stirred to dissolve completely to obtain a solution; then NH was added dropwise to the above BiOI dispersion 4 VO 4 Dissolve the solution, and then continue magnetic stirring for 45 minutes to obtain a mixed solution; after the stirring is completed, transfer the mixed solution to a stainless steel high-pressure reactor equipped with a polytetrafluoroethylene liner, and put it into an electric constant temperature blast drying oven for heat treatment at 160°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com