Preparation method of activated zeolite molecular sieve supported titanium dioxide photocatalysis material

A photocatalytic material, zeolite molecular sieve technology, applied in the field of preparation of activated zeolite molecular sieve loaded titanium dioxide photocatalytic material, can solve the problems of weak adsorption performance of natural zeolite and low photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

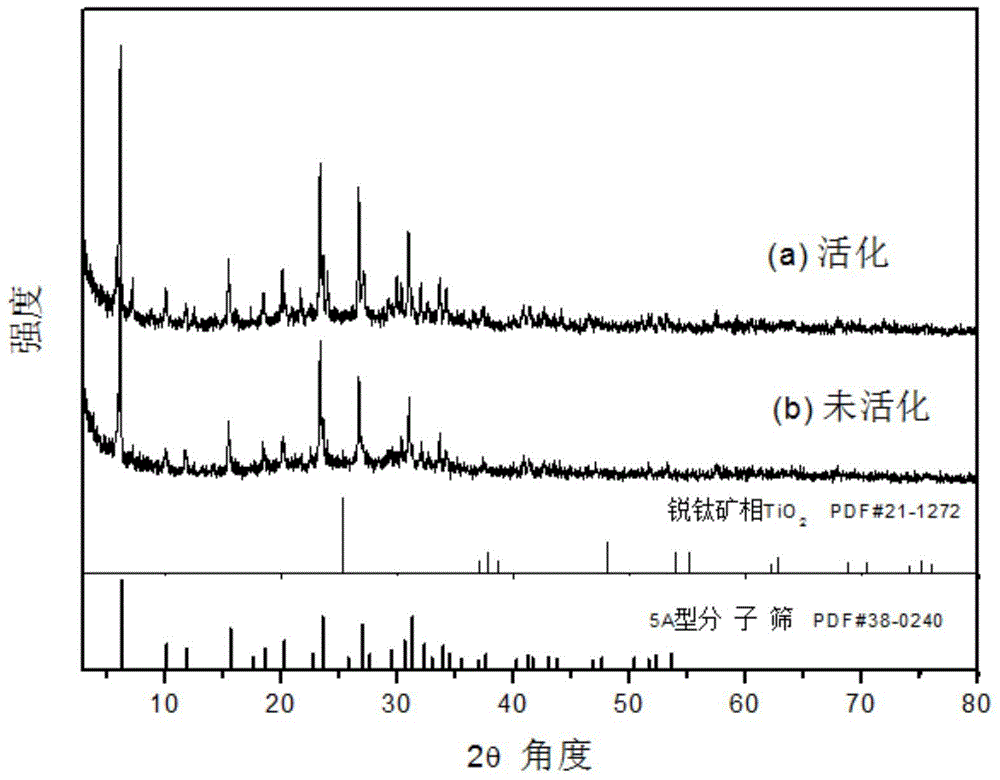

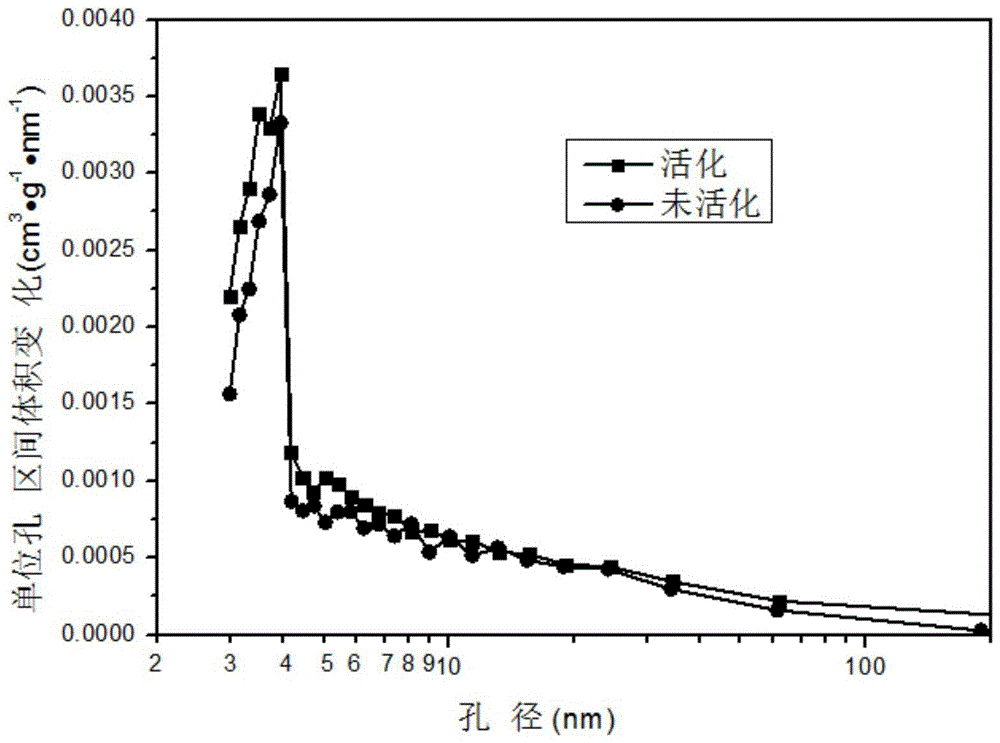

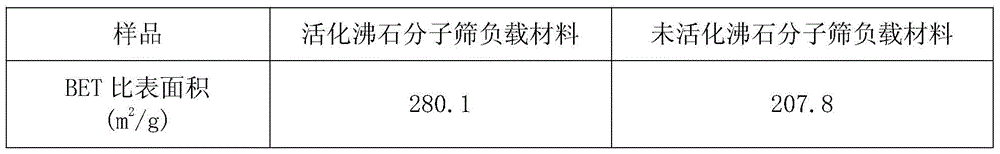

[0024] Such as figure 1 , figure 2 As shown, the present invention provides a kind of preparation method of activated zeolite molecular sieve loaded titanium dioxide photocatalytic material, comprises the following steps:

[0025] Step S1: Activate the natural zeolite molecular sieve to obtain the activated zeolite molecular sieve, which specifically includes, Step S1a: Pour the natural zeolite molecular sieve into a beaker, and rinse with distilled water until the rinse solution is no longer turbid; Step S1b: Wash the natural zeolite molecular sieve Put the molecular sieve together with the beaker into an oven for drying at a temperature of 75-90°C. After drying, move it into a high-temperature furnace for calcination for 0.5-2 hours, and adjust the temperature in the furnace to 170-195°C to obtain activated zeolite molecular sieves.

[0026] Step S2: Mix and stir the activated zeolite molecular sieve, tetrabutyl titanate, acetic acid, nitric acid, and absolute ethanol, and...

Embodiment 1

[0031] The preparation method of the activated zeolite molecular sieve loaded titanium dioxide photocatalytic material with a mass ratio of 1:0.5 comprises the following steps:

[0032] (1) The natural zeolite molecular sieve is activated to obtain activated zeolite molecular sieve:

[0033] Pour a certain amount of natural zeolite molecular sieve (5A) into a beaker, rinse several times with distilled water until the liquid is no longer turbid, then put the cleaned natural zeolite molecular sieve (5A) together with the beaker into an oven for drying, and the oven temperature is 80 °C, after drying, move it into a high-temperature furnace for calcination for 1 hour, and adjust the temperature in the furnace to 180 °C to finally obtain an activated zeolite molecular sieve (5A).

[0034] (2) Mix and stir the activated zeolite molecular sieve, tetrabutyl titanate, acetic acid, nitric acid and absolute ethanol, and obtain the activated zeolite molecular sieve-loaded titanium dioxide ...

Embodiment 2

[0037] The preparation method of the activated zeolite molecular sieve loaded titanium dioxide photocatalytic material with a mass ratio of 1:1 comprises the following steps:

[0038] (1) The natural zeolite molecular sieve is activated to obtain activated zeolite molecular sieve:

[0039] Pour a certain amount of natural zeolite molecular sieve (5A) into a beaker, rinse several times with distilled water until the liquid is no longer turbid, then put the cleaned natural zeolite molecular sieve (5A) together with the beaker into an oven for drying, and the oven temperature is 80 °C, after drying, move it into a high-temperature furnace for calcination for 1 hour, and adjust the temperature in the furnace to 180 °C to finally obtain an activated zeolite molecular sieve (5A).

[0040] (2) Mix and stir the activated zeolite molecular sieve, tetrabutyl titanate, acetic acid, nitric acid and absolute ethanol, and obtain the activated zeolite molecular sieve-loaded titanium dioxide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com