Full-automatic spraying template device

A fully automatic and prototype technology, applied in spraying devices, devices for coating liquid on surfaces, coatings, etc., can solve the problems of expensive hanging cup equipment, unstable coating quality, rising labor costs, etc., and improve paint utilization High efficiency, saving working space and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

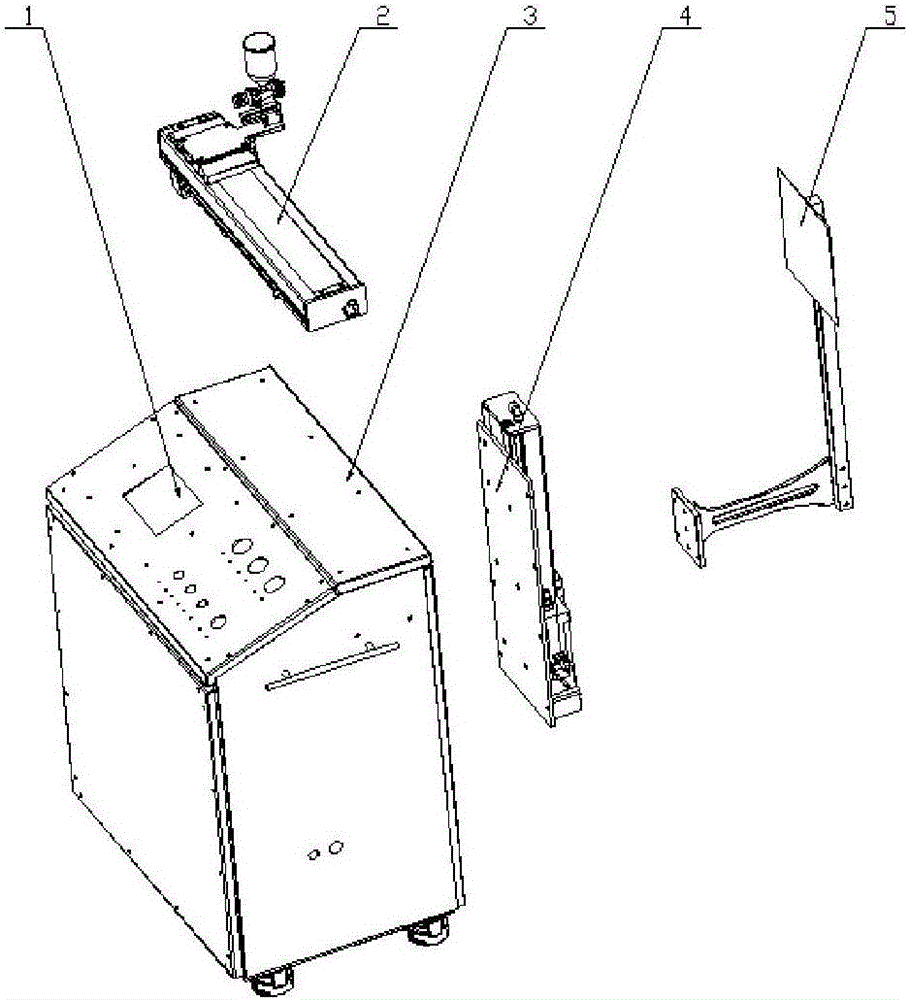

[0023] Such as figure 1 , figure 2 As shown, a fully automatic spraying sample device includes five major components including an operation component 1, a horizontal screw module 2, a box body 3, a vertical screw module 4, and a sample bracket 5; the operation component 1 is installed in a box The front end of the body composition 3 is fixed by screws; the horizontal screw module 2 is placed on the horizontal screw mounting seat 11 in the box composition 3 and fixed with screws; the vertical screw module 4 is placed in the box composition 3 , fixed with screws; the template support 5 is fastened on the vertical screw module 4 with screws.

Embodiment 2

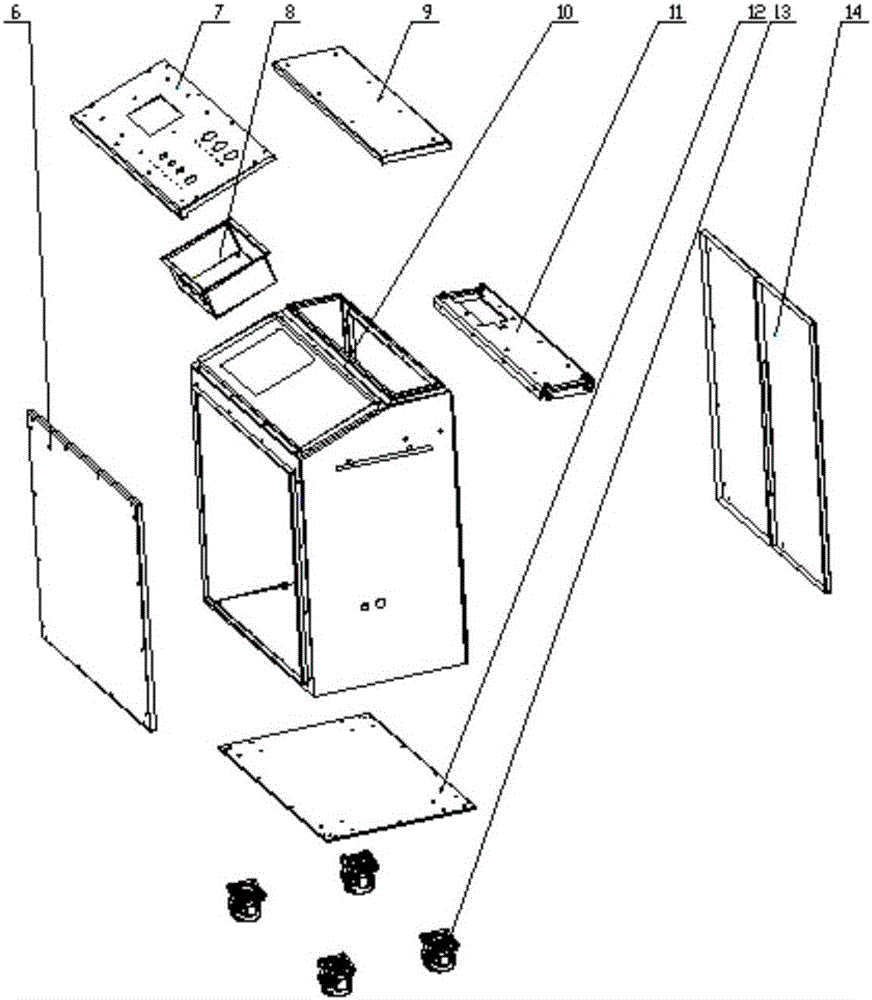

[0025] Such as image 3 As shown, a box assembly of a fully automatic spraying model device includes a front cover plate 6, an operation panel 7, a display stand 8, an upper cover plate 9, a box body 10, a horizontal screw mounting seat 11, a bottom plate 12, and casters Composition 13, rear cover plate 14, a total of nine parts; the display screen seat 8 is installed on the operation panel 7, fixed with screws; front cover plate 6, operation panel 7, upper cover plate 9, horizontal screw mounting seat 11 , The bottom plate 12 and the rear sealing plate 14 are fastened and connected with the box body 10 with screws.

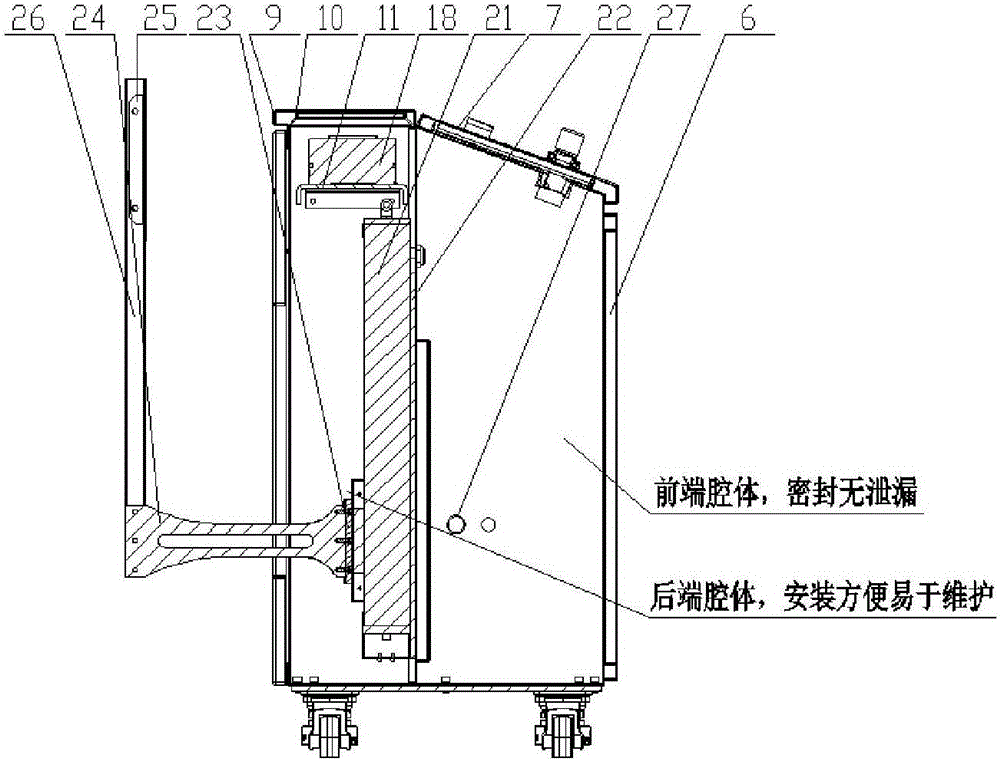

[0026] The assembled box is composed of two cavities. The front cavity is composed of the operation panel 7, the front sealing plate 6 and the box body 10. The angle between the operation panel 7 and the vertical is 50°, which is used to install the explosion-proof display screen. It is convenient for personnel to operate and control. The entire cavity is seale...

Embodiment 3

[0029] An operation component of a fully automatic spraying model device, including an explosion-proof display screen, a start button, a stop button, an emergency stop switch, a pressure regulating valve, a pressure gauge, etc., the parts are installed on the box operation panel 7, and tightened with screws Fixed connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com