Preparation method of PtCu alloy nanospheres

An alloy nano and complex technology, applied in the field of nano materials, can solve the problems of complex preparation technology of platinum copper alloy, existence of by-products, unsuitable for commercialization, etc., and achieve the effects of low cost, easy control and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

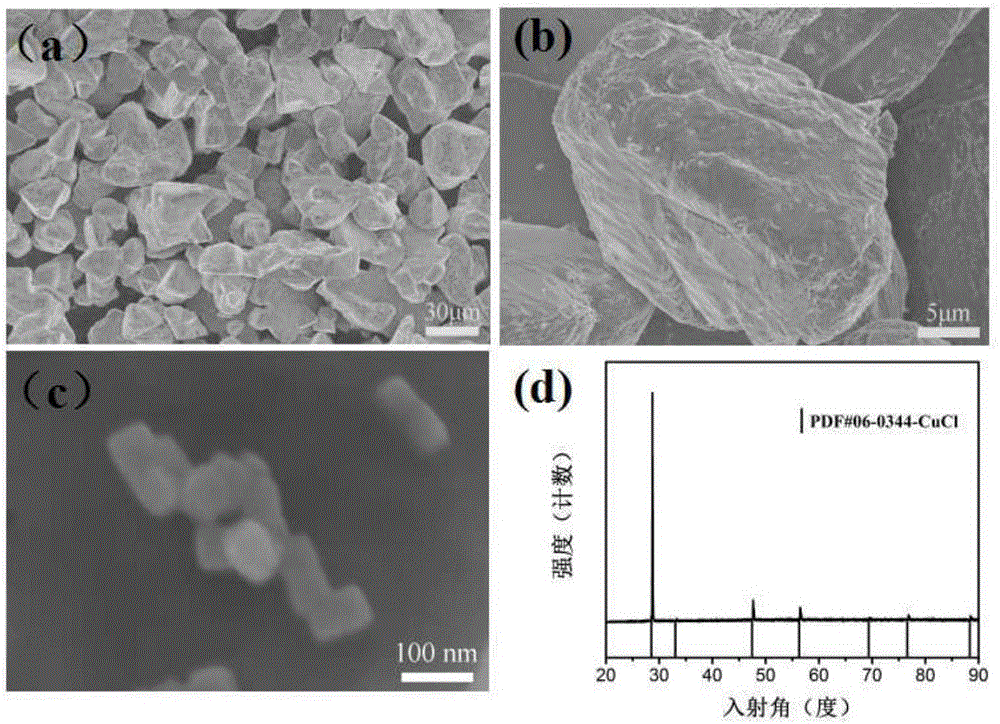

[0027] (1) Take 0.5 g of commercially available yellow-green CuCl raw material, wash CuCl with dilute HCl (5 mL) of pH = 2, obtain 5 mL of acidic solution containing white powder, let it stand, remove the supernatant, and then use deoxygenated non- Washed twice with water and ethanol, and then dried under argon atmosphere at room temperature to obtain pure CuCl white powder, as figure 1 Figures (c) and (d) in (c);

[0028] (2) Equipped with a three-necked flask under an argon atmosphere for 10ml K 2 PtCl 6 (concentration is 15mM), saturated KCl solution, 10ml deionized water to remove excess dissolved oxygen (argon gas is passed through to remove the oxygen therein);

[0029] (3) the pure CuCl white powder obtained in step (1) is all added to the saturated KCl solution that removes dissolved oxygen in advance in the 2ml step (2), due to the reaction equation (1), a colorless complex solution is formed;

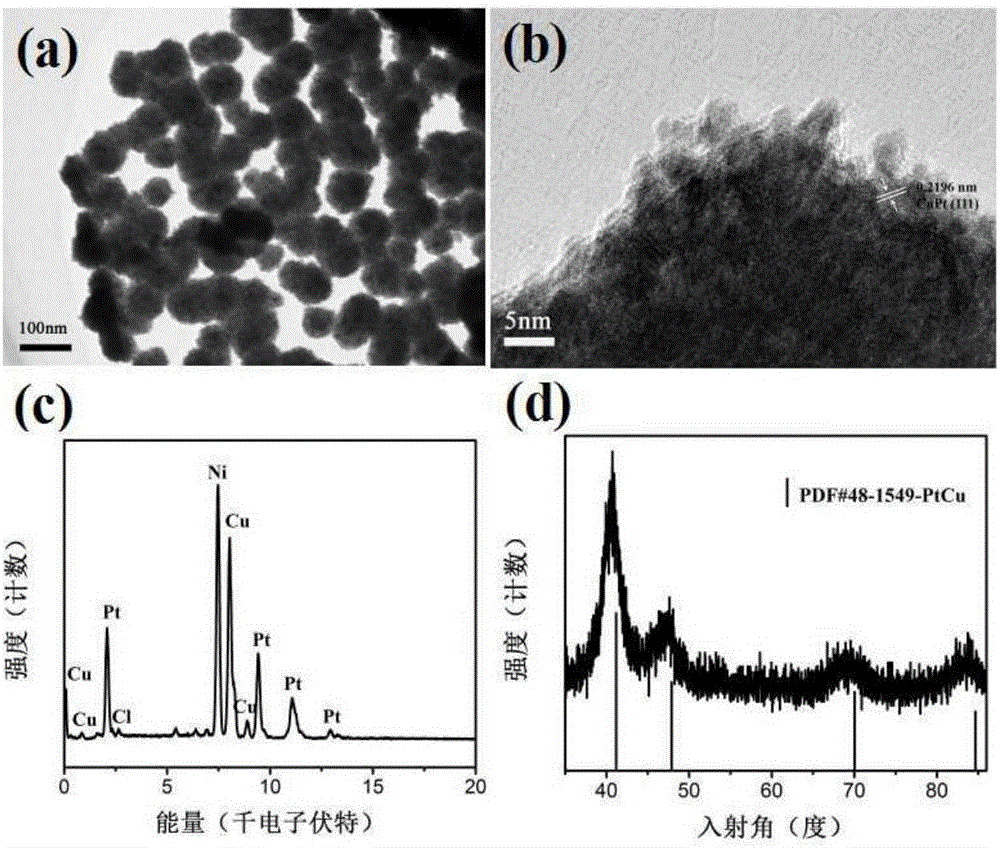

[0030] (4) Quickly take 1ml of the complexing solution to 10mL of deio...

Embodiment 2

[0035] Other steps are with embodiment 1, and difference is the K in step (2) 2 PtCl 6 The concentration was changed from 15mM to 18mM. The experiment proved that the product obtained in this example was PtCu alloy nanospheres.

Embodiment 3

[0037] Other steps are with embodiment 1, and difference is the K in step (2) 2 PtCl 6 The concentration was changed from 15mM to 5mM. The experiment proved that the product obtained in this example was PtCu alloy nanospheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com