A high-speed helical milling method for pockets based on spin-up auxiliary lines

A technology of helical milling and auxiliary lines, which is applied in the direction of milling machine equipment, milling machine equipment details, instruments, etc., can solve the problems of large cutting tool track length and low cutting efficiency, so as to reduce the tool track length, improve production efficiency and reduce repetition The effect of stock removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] 1 Helical tool path generation algorithm

[0062] 1.1 Helical tool path generation process

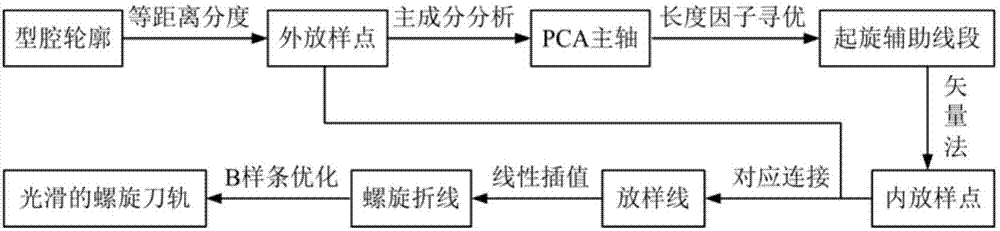

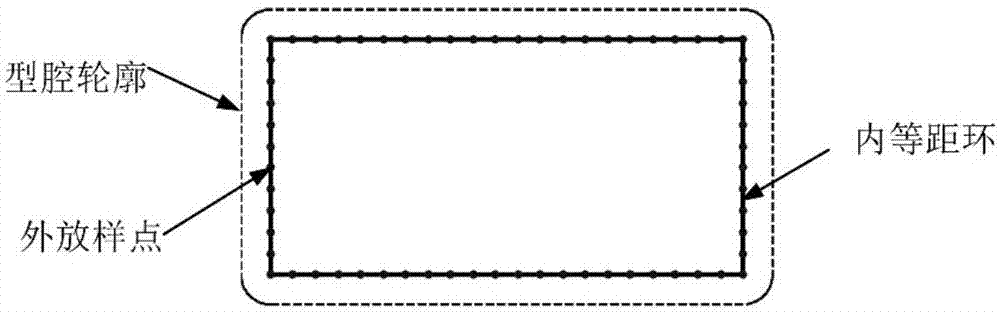

[0063] Record the contour curve of any convex boundary cavity as f(t). If the tool radius is set to R, then the distance between tool paths is δ∈(0,2R). Taking a rectangular cavity as an example, the flow of the spiral tool path generation algorithm is as follows: figure 1 As shown, the details are as follows:

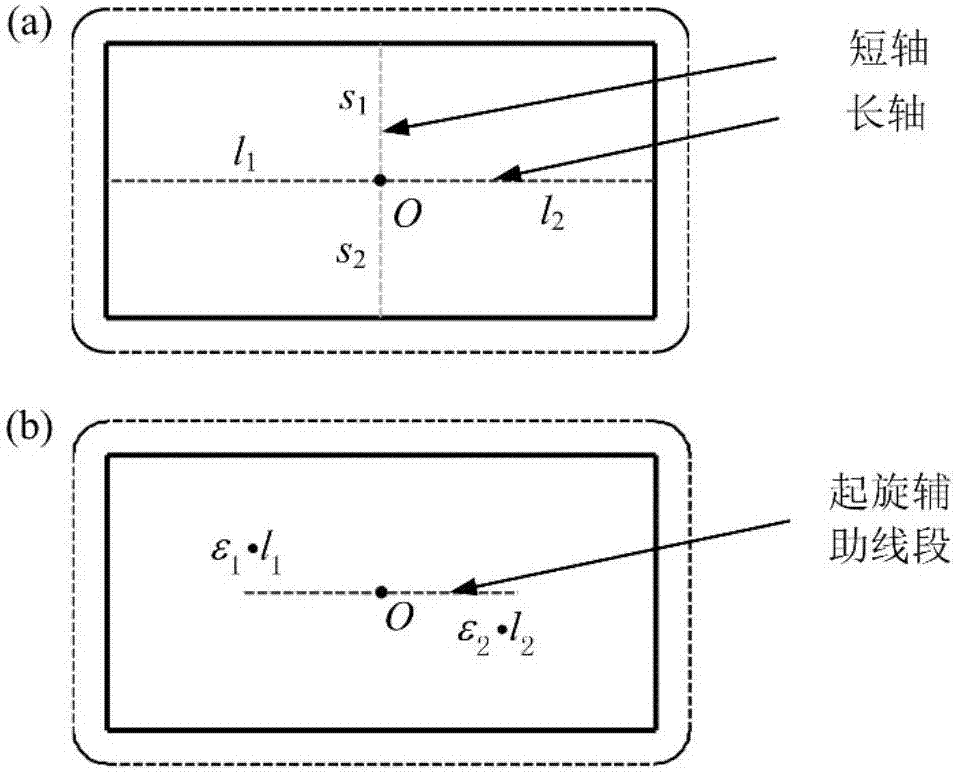

[0064] (1) For the inner equidistant ring of the equidistant indexing cavity contour, the PCA method is used to calculate the two major axes of the outer stakeout points on the inner equidistant ring of the cavity contour, and then the length factor is used to optimize and intercept part of the long principal axis as The spin-up auxiliary line for cavity lofting, such as image 3 as shown in (b);

[0065] (2) Apply the vector method to obtain the point closest to the outer stakeout point on the spinning auxiliary line, that is, the inner stakeout point, correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com