Oil electro-hydraulic and hydrostatic hybrid driving system

A hydrostatic drive, oil-electro-hydraulic technology, which is used in transmissions driven by electric motors, transmissions with reciprocating piston internal combustion engines, railway transportation, etc., can solve problems such as poor low-speed characteristics and low overall machine efficiency, and reduce The effect of installed power, speeding up the start-up time, and improving the power density of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

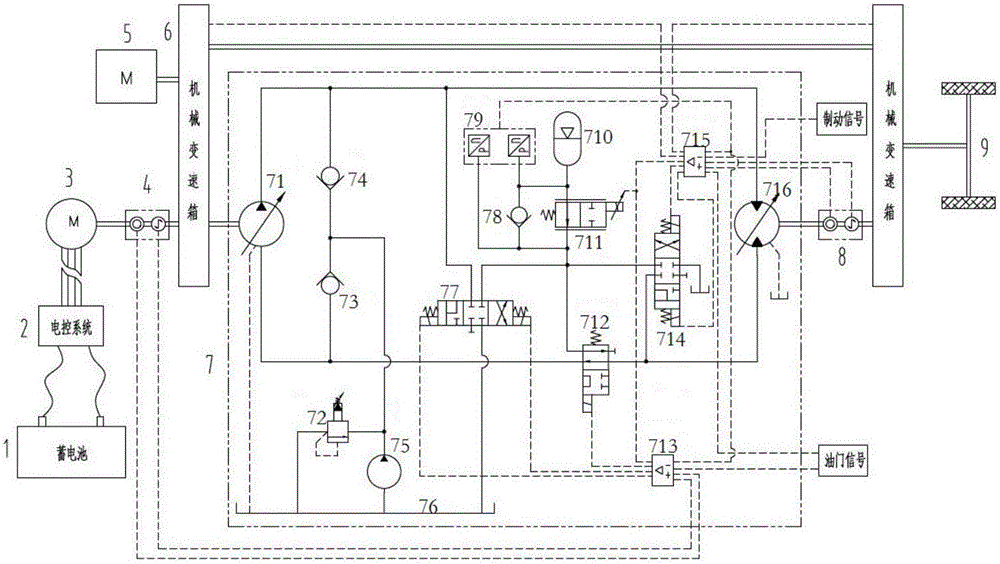

[0017] Attached below figure 1 The present invention will be further described in detail with specific embodiments. Since the acceleration torque is the key factor in the power problem of the whole vehicle, the energy consumption of the motor is large during the acceleration period, and the current impact is large, and the hydrostatic system has the advantages of high power density and convenient stepless speed regulation, so the invention uses the innovatively designed static The hydraulic system solves the problems of the vehicle's low-speed stepless speed regulation characteristics, acceleration and starting capabilities, braking capabilities and power density.

[0018] Such as figure 1 As shown, the system of the present invention mainly includes a battery 1, an electronic control system 2, a motor 3, a first torque speed sensor 4, a diesel engine 5, a first mechanical transmission 6, a hydrostatic drive system 7, a second torque speed sensor 8, a first Two mechanical tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com