Screw conveyer blade with abrasion-resistant coating

A screw conveyor and wear-resistant coating technology, applied in coating, metal material coating process, packaging, etc., can solve the problems of affecting material transportation, reducing blade service life, failure, etc., to ensure transmission, good high temperature resistance Grinding performance and the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

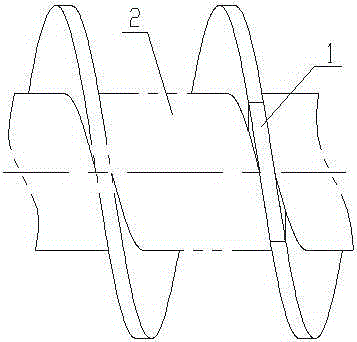

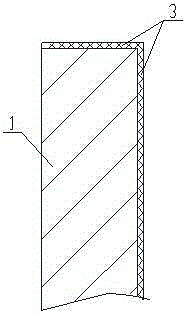

[0012] Example figure 1 and figure 2 As shown, the present invention has a screw conveyor blade with a wear-resistant coating. The blade 1 is fan-shaped and has a space distortion or a plane shape. The blade 1 is spirally arranged on the rotating shaft 2. The working of the blade 1 A wear-resistant coating 3 is provided on the side surface and / or the top surface of the arc, and the wear-resistant coating 3 is sprayed by a powder plasma spray welding process and alloy powder is used as a filling material.

[0013] Preferably, the alloy powder is nickel-based alloy powder containing 60wt% tungsten carbide.

[0014] Preferably, the alloy powder is a mixed powder of Ni-based alloy powder and WC particles, wherein the mass percentage of WC particles in the mixed powder is 15-70%.

[0015] Preferably, the wear-resistant coating 3 has a thickness of 3-5 mm.

[0016] The blade uses the plasma arc as the high-temperature heat source, and the alloy powder as the filling material. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com