Preparation method of magnesium oxide for concrete

A magnesia and concrete technology, which is applied in the field of magnesia preparation for concrete, can solve problems such as difficulty in guaranteeing activity, difficult control of concrete shrinkage effect, uneven firing weight of concrete magnesia, etc., and achieves low cost and stable weight , Great social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0061] In this preparation example, the magnesium oxide raw material (by weight) for concrete includes 100% by weight of commercially available magnesite.

[0062] The particle size range of this preparation example is 10-30mm. The particle diameter of the raw material is the median value of the main particles in the particle diameter range, and basically all the particle diameters are within the range (the same below).

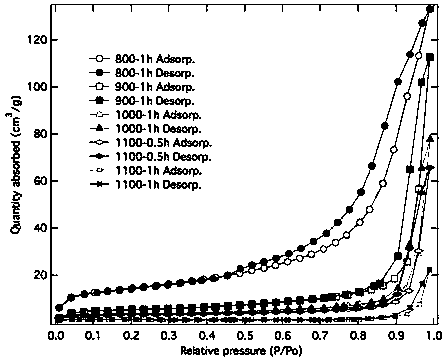

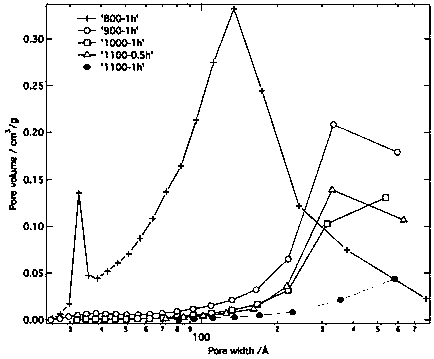

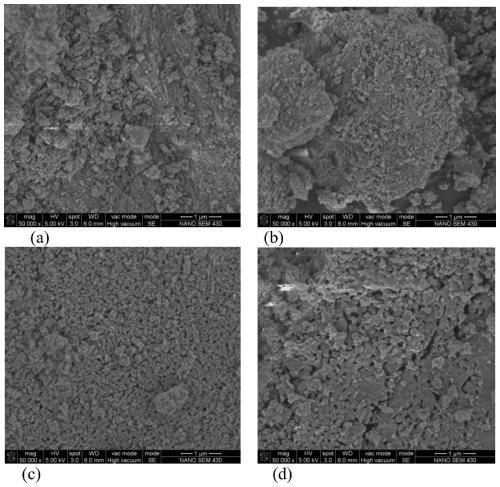

Embodiment 1-9

[0064] The calcination temperatures and calcination conditions for Examples 1-9 are listed in Table 1 below.

[0065] During the calcination process, a hollow rotary kiln is used According to working example 1, the raw material is calcined according to the conditions listed in Examples 1-9, and the heat value is 9000-9500Kcal / Nm 3 Class I natural gas is used as fuel. After calcination, the calcined material is ground to a fineness (80 μm sieve) of less than 5%.

[0066] Table 1

[0067]

[0068] *Note: During the calcination process, the calcination temperature is mainly controlled around the median value of the temperature range of the colorimetric pyrometer, and fluctuates up and down within this temperature range, and does not exceed the boundary value (the same below).

[0069] It can be seen from the implementation effect that when the particle size of raw materials is within the range of 10-30mm, the dust in the kiln is generally relatively high, which affects the ...

preparation example 2

[0071] In this preparation example, the magnesium oxide raw material (by weight) for concrete includes 100% of commercially available magnesite.

[0072] The particle size range of this preparation example is 30-60mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com