Method for stabilizing arsenic-containing sludge by kaolin geopolymer

A technology of geopolymer and metakaolin powder, applied in cement production, solid waste management, sustainable waste treatment, etc., can solve the problems of high cost, unfavorable large-scale use by enterprises, etc., to enhance stability, reduce diffusion and harm , the effect of improving the compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

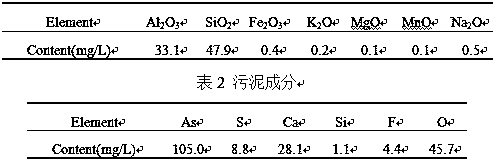

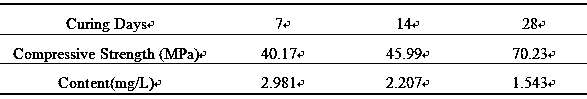

[0021] Example 1: The components of kaolin in this example are shown in Table 1. The arsenic-containing sludge comes from the sulfuric acid workshop of a zinc smelter in Southwest China after removing arsenic in wastewater by lime neutralization and precipitation. The main components are shown in Table 2 shown;

[0022] Table 1 Kaolin composition

[0023]

[0024] A method for stabilizing arsenic-containing sludge with kaolin polymer, the specific steps are as follows:

[0025] (1) Calcining kaolin at a temperature of 650°C for 6 hours to obtain metakaolin, ball milling metakaolin for 40 minutes, and sieving to obtain metakaolin powder; wherein the ball milling speed is 120 r / min, and the particle size of metakaolin powder is less than 0.45 mm;

[0026] (2) Add deionized water to metakaolin powder in step (1) and mix evenly to obtain mixture A; wherein the mass ratio of deionized water to metakaolin powder is 0.4:1;

[0027] (3) Under stirring conditions, add the alkali a...

Embodiment 2

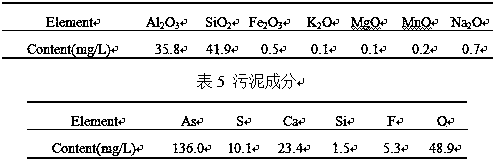

[0035] Example 2: The components of kaolin in this example are shown in Table 4. The arsenic-containing sludge comes from the sulfuric acid workshop of a zinc smelter in Southwest China after removing arsenic in wastewater by lime neutralization and precipitation. The main components are shown in Table 5 shown;

[0036] Table 4 Kaolin composition

[0037]

[0038] A method for stabilizing arsenic-containing sludge with kaolin polymer, the specific steps are as follows:

[0039] (1) Calcining kaolin at a temperature of 550°C for 8 hours to obtain metakaolin, ball milling metakaolin for 80 minutes, and sieving to obtain metakaolin powder; wherein the ball milling speed is 80 r / min, and the particle size of metakaolin powder is less than 0.45 mm;

[0040] (2) Add deionized water to metakaolin powder in step (1) and mix evenly to obtain mixture A; wherein the mass ratio of deionized water to metakaolin powder is 0.3:1;

[0041] (3) Under stirring conditions, add the alkali ac...

Embodiment 3

[0049] Example 3: The cement composition of this example is shown in Table 7. The arsenic-containing sludge comes from the sulfuric acid workshop of a zinc smelter in Southwest China after removing arsenic in wastewater by lime neutralization and precipitation. The main components are shown in Table 8 shown;

[0050] Table 7 Kaolin composition

[0051]

[0052] A method for stabilizing arsenic-containing sludge with kaolin polymer, the specific steps are as follows:

[0053] (1) Calcining kaolin at a temperature of 600°C for 7 hours to obtain metakaolin, ball milling metakaolin for 60 minutes, and sieving to obtain metakaolin powder; wherein the ball milling speed is 100 r / min, and the particle size of metakaolin powder is less than 0.45 mm;

[0054] (2) Add deionized water to metakaolin powder in step (1) and mix evenly to obtain mixture A; wherein the mass ratio of deionized water to metakaolin powder is 0.35:1;

[0055] (3) Under stirring conditions, add the alkali act...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com