Preparation method of polyamide 56 having flame retardant property and polyamide 56 fiber

A flame retardant, polyamide technology, applied in the field of polyamide 56 fibers to avoid branching and reticulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

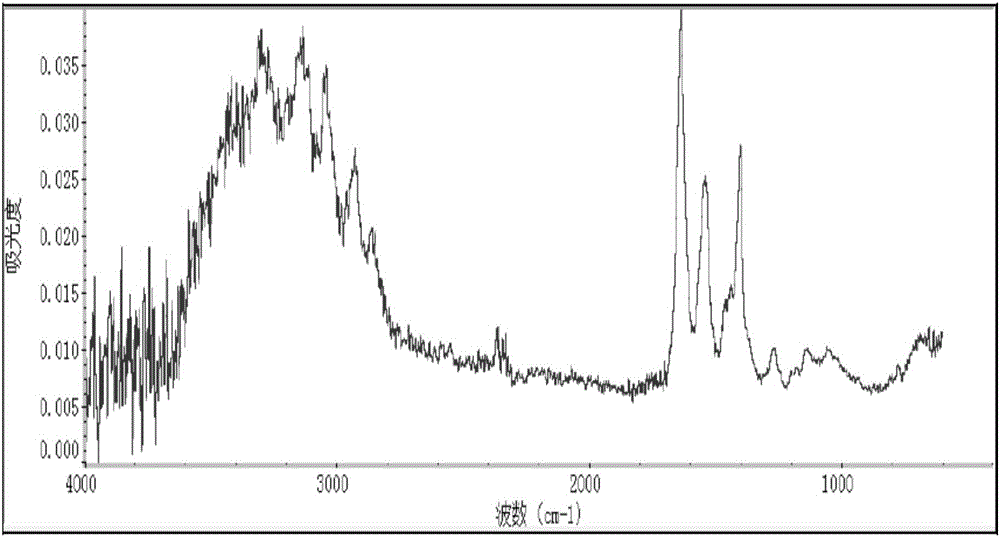

Image

Examples

Embodiment 1

[0045] Select 3-hydroxyphenylphosphine propionic acid (CEPPA) to be flame retardant used in the present invention, this is because its production technique is stable, and market supply is sufficient, has relative price advantage, and active ingredient content is high (P content 14.5%) , has outstanding flame retardant effect.

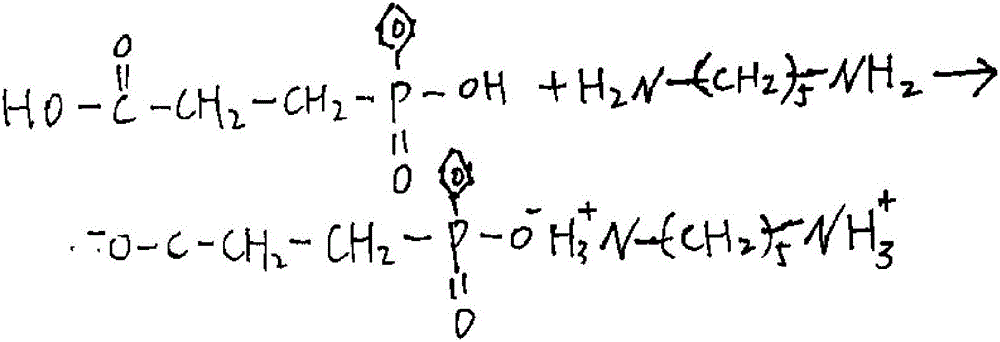

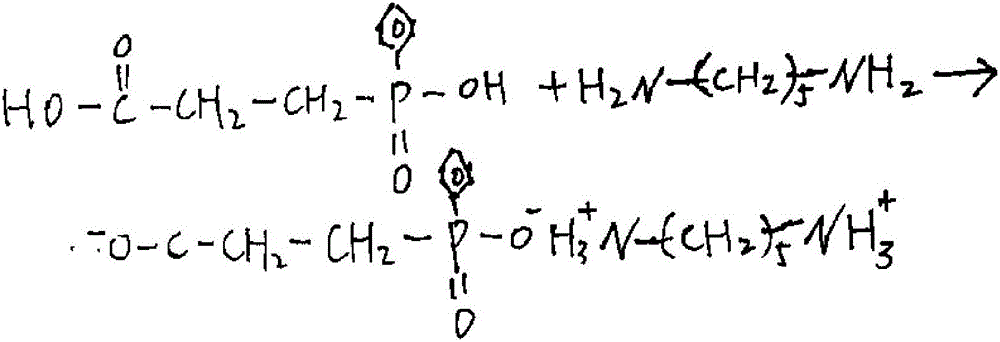

[0046] Select 1 mole of CEPPA and 1 mole of pentamethylenediamine to mix, and prepare an aqueous solution with a concentration of 60-0.5% at a temperature of 45-50° C. and a medium pH value of 7.3-7.5 for future use.

[0047] Mix pentamethylenediamine and adipic acid in a polymerization tank at a molar ratio of 1:1 and perform a pre-amidation reaction to obtain a polyamide 56 prepolymer with a certain degree of polymerization, which will be used as a polyamide 56 macromolecule in the future basic main chain. During the pre-amidation reaction, the pressure inside the polymerization tank is 1.75-2.0 MPa, the temperature is 210-250° C., and the reaction t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com