High-wear-resistance non-woven fabric

A non-woven fabric, high wear-resistant technology, applied in the direction of non-woven fabrics, textiles and papermaking, single-component polyolefin artificial filament, etc., can solve the problems of low market demand and low wear resistance, and achieve the goal of avoiding separation Branches and too thick, optimize wear resistance, promote the effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

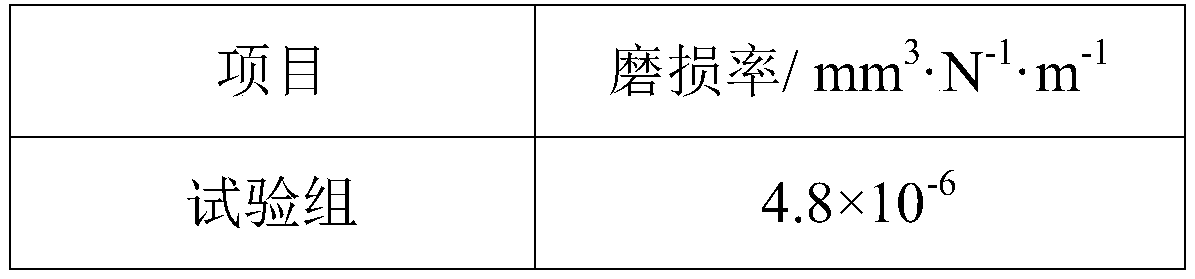

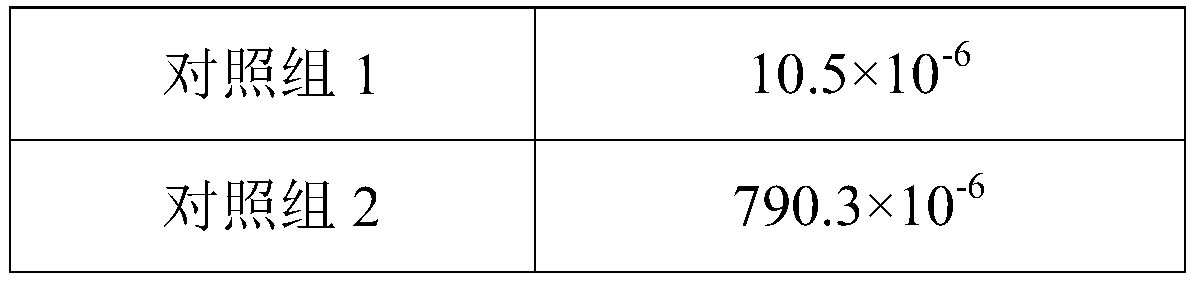

Examples

Embodiment 1

[0015] A high wear-resistant non-woven fabric. The non-woven fabric is produced by a continuous one-step process of high-temperature melting, spinning, laying, and hot-pressing coiling by using a mixture of polypropylene and nano-zinc oxide as a raw material.

Embodiment 2

[0017] A high wear-resistant non-woven fabric, the non-woven fabric adopts the mixture of polypropylene and nano-zinc oxide as raw material, and is produced by continuous one-step process of high-temperature melting, spinning, laying, and hot-pressing;

[0018] Wherein, the weight ratio of the polypropylene to the nano zinc oxide is 1:12;

Embodiment 3

[0020] A high wear-resistant non-woven fabric, the non-woven fabric adopts the mixture of polypropylene and nano-zinc oxide as raw material, and is produced by continuous one-step process of high-temperature melting, spinning, laying, and hot-pressing;

[0021] Wherein, the weight ratio of the polypropylene to the nano zinc oxide is 1:15;

[0022] The nano-zinc oxide is modified nano-zinc oxide, and the preparation process of the modified nano-zinc oxide is as follows: in a nitrogen atmosphere, add an appropriate amount of KH570 and triethylamine to the acetone solution of nano-zinc oxide, mechanically stir, and reflux React, filter, wash, vacuum dry, grind and sieve to obtain modified nano-zinc oxide;

[0023] The speed of described mechanical stirring is 450r / min, and the time is 1.8h;

[0024] The time of the reflux reaction is 4h;

[0025] The temperature of the vacuum drying is 100°C, and the time is 55min;

[0026] The preparation method of the acetone solution of nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com