Toughened power cable CV environmentally-friendly pipe and preparation method thereof

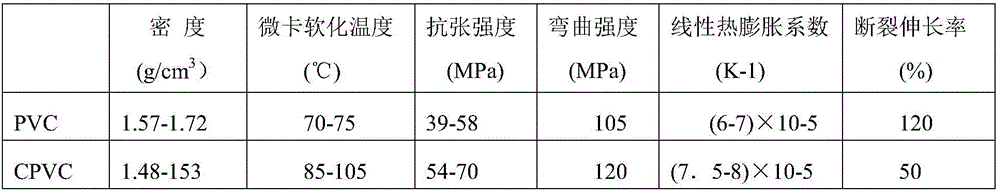

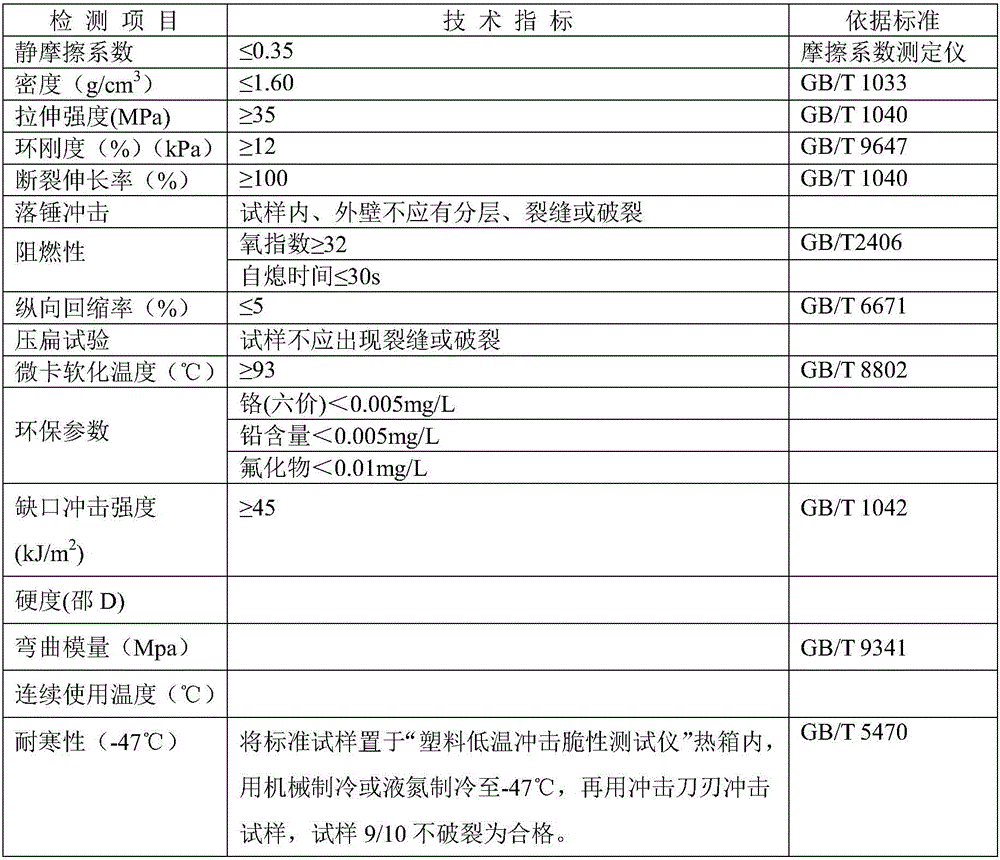

A polyvinyl chloride and composite material technology is applied in the field of toughened power cable CV environmental protection tube and its preparation, which can solve the problems of difficulty in meeting the technical index requirements of the cable protection tube, poor toughness, etc., and achieve the effects of environmental safety and broad market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The process is as follows:

[0042] Premixing→extrusion→setting→cooling→cutting→product

[0043] (1) Preparation of premix:

[0044] In parts by weight, after measuring 60 parts of CPVC, 40 parts of PVC, and 4 parts of calcium / zinc stabilizer, put them into a low-speed mixer at room temperature and with a rotation speed of 100 rpm. After stirring for 2 minutes, add 3 parts of A606ACR and 2 parts of M51ACR slowly during the stirring. 1.5 parts of OP wax, 1.8 parts of oxidized polyethylene wax, 8 parts of talcum powder, 8 parts of hydrotalcite, 1 part of 1010 antioxidant, 13 parts of TPEE, and then stirred for 3 minutes to obtain a premix;

[0045] (2) Preparation of toughened power cable CV environmental protection tube:

[0046] Put the premix prepared in step (1) into a conical twin-screw extruder with a temperature of 110°C, 160°C, 175°C, 180°C, 175°C, 170°C, and a screw speed of 100rpm. Extrude the tube blank (inner diameter 100mm, thickness 5mm), after the tube b...

Embodiment 2

[0048] (1) Preparation of premix:

[0049]In parts by weight, after measuring 55 parts of CPVC, 45 parts of PVC, and 3.5 parts of calcium / zinc stabilizer, put them into a low-speed mixer at room temperature and with a rotation speed of 100 rpm. After stirring for 2 minutes, slowly add 2 parts of KM-355ACR, B564ACR 2 parts, 1.5 parts of OP wax, 1.6 parts of polyethylene wax, 10 parts of talcum powder, 7 parts of hydrotalcite, 1 part of 1010 antioxidant, 12 parts of TPEE, and then stirred for 3 minutes to obtain a premix;

[0050] (2) Preparation of toughened power cable CV environmental protection tube:

[0051] Put the premix prepared in step (1) into a conical twin-screw extruder with a temperature of 110°C, 160°C, 175°C, 175°C, 175°C, 170°C and a screw speed of 100rpm, and plasticize Extrude the tube blank (inner diameter 100mm, thickness 5mm), after the tube blank is shaped, cooled and cut, the toughened power cable CV environmental protection tube can be obtained.

Embodiment 3

[0053] (1) Preparation of premix:

[0054] In parts by weight, after measuring 80 parts of CPVC, 20 parts of PVC, and 4.5 parts of calcium / zinc stabilizer, put them into a low-speed mixer at room temperature and with a rotation speed of 105 rpm. After stirring for 2 minutes, add 3 parts of A606ACR and 3 parts of KM334ACR slowly during the stirring. 1 part, 2 parts of OP wax, 1.6 parts of polyethylene wax, 1 part of 316 wax, 6 parts of talcum powder, 10 parts of hydrotalcite, 1 part of 245 antioxidant, 16 parts of TPEE, and continue stirring for 3 minutes to obtain a premix;

[0055] (2) Preparation of toughened power cable CV environmental protection tube:

[0056] Put the premix prepared in step (1) into a conical twin-screw extruder with a temperature of 110°C, 160°C, 175°C, 180°C, 180°C, 170°C and a screw speed of 100rpm, and plasticize Extrude the tube blank (inner diameter 100mm, thickness 5mm), after the tube blank is shaped, cooled and cut, the toughened power cable CV...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com