Protective film with heating-reducible adhesion and preparation method thereof

A protective film and adhesive technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of low work efficiency, easy residues on the casing or screen, and manual tearing of protective films. , to achieve the effect of easy operation, simple preparation method and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

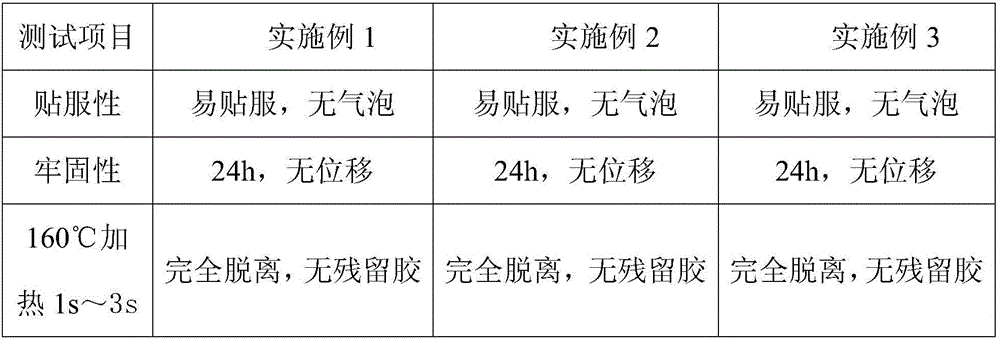

Embodiment 1

[0029] Components of the heating adhesive 2: 20% by weight of polyurethane resin, 10% by weight of MDI blocked isocyanate curing agent, 65% by weight of ketone organic solvent, and 5% by weight of Expandable microsphere foaming agent; wherein, the particle diameter of the self-expanding microsphere in the self-expanding microsphere foaming agent is 15 μm.

[0030] The preparation of heating viscosifying glue 2 comprises the following steps:

[0031] a) Add the ketone organic solvent and self-expanding microsphere foaming agent into the mixing tank for stirring, the stirring speed is 150r / min, and the stirring time is 30min.

[0032] b) adding polyurethane resin into the solution treated in step a), and stirring for 7 minutes.

[0033] c) Add an MDI blocked isocyanate curing agent into the mixing barrel in the solution treated in step b), and stir for 10 minutes, so as to prepare the heat-viscosity-reducing adhesive 2.

[0034] The preparation of the heat-reducing viscosity-r...

Embodiment 2

[0040] The components of the heating viscosifying adhesive 2: 55% by weight of polyester resin, 8% by weight of TDI blocked isocyanate curing agent, 30% by weight of benzene organic solvent, and 7% by weight of A self-expanding microsphere foaming agent; wherein, the particle diameter of the self-expanding microsphere in the self-expanding microsphere foaming agent is 20 μm.

[0041] The preparation of heating viscosifying glue 2 comprises the following steps:

[0042] a) Add benzene organic solvent and self-expanding microsphere foaming agent into the mixing tank for stirring, the stirring speed is 180r / min, and the stirring time is 25min.

[0043] b) adding polyester resin into the solution treated in step a), and stirring for 10 minutes.

[0044] c) Adding TDI blocked isocyanate curing agent into the solution treated in step b), and stirring for 8 minutes, so as to prepare heating viscosifying adhesive 2.

[0045] The preparation of the heat-reducing viscosity-reducing pr...

Embodiment 3

[0051] Components of the heating adhesive 2: 90% by weight of acrylic resin, 0.1% by weight of IPDI isocyanurate curing agent, 9% by weight of deionized water, and 0.9% by weight of A self-expanding microsphere foaming agent; wherein, the particle diameter of the self-expanding microsphere in the self-expanding microsphere foaming agent is 25 μm.

[0052] The preparation of heating viscosifying glue 2 comprises the following steps:

[0053] a) Add benzene organic solvent and self-expanding microsphere foaming agent into the mixing tank for stirring, the stirring speed is 200r / min, and the stirring time is 30min.

[0054] b) adding acrylic resin into the solution treated in step a), and stirring for 10 minutes.

[0055]c) Adding IPDI isocyanurate curing agent into the solution treated in step b), and stirring for 5 minutes, so as to prepare the heat-viscosity-reducing adhesive 2.

[0056] The preparation of the heat-reducing viscosity-reducing protective film comprises the fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com