Slow-release chlorine dioxide solid soap and preparation method thereof

A chlorine dioxide precursor, chlorine dioxide technology, applied in chemical instruments and methods, soap detergents and other compounding agents, soap detergent compositions, etc., can solve problems such as difficult storage, transportation, and poor slow-release effect , to achieve the effect of both aesthetics, simple formula and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Weigh 50g of sodium stearate (sodium octadecanoate) and heat to 150°C to melt, and stir evenly. Add 5ml of high-concentration sodium chlorite solution with a concentration of 10% dropwise. After stirring evenly, add 0.1g of oxalic acid to activate it. Add 1ml of essence and 0.1g of food coloring agent to the activated solution in turn, stir well and pour into the mold for cooling.

[0041] Put the prepared sample into 0.125m 3 In the airtight test chamber, drop the formaldehyde concentration to 1.38mg / m 3 , after 90min the concentration of formaldehyde drops to 0.01mg / m 3 .

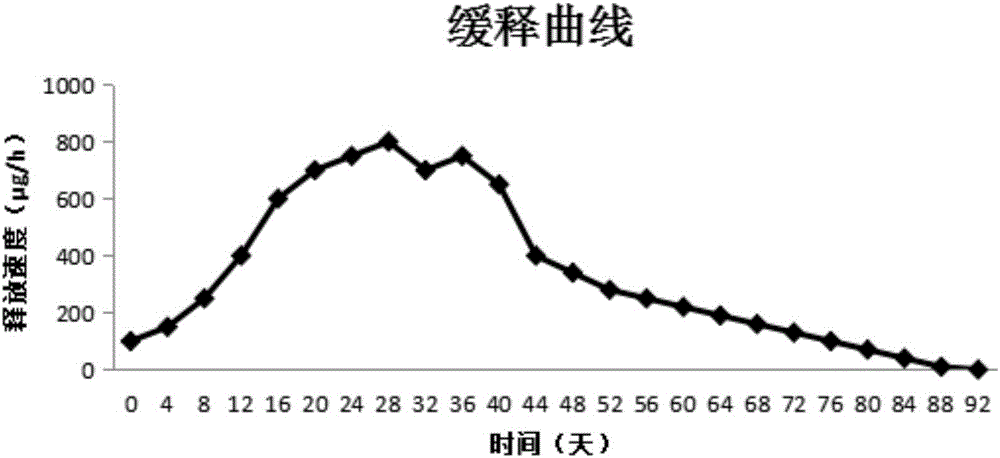

[0042] With reference to the test method in the patent document CN105145626A to detect the sustained release rate, the results are as follows figure 1 , the results showed that the release rate was greater than 150 μg / h for 64 days.

Embodiment 2

[0044] Weigh 40g of sodium stearate and heat to 150°C to melt and stir evenly. Add 10ml of high-concentration sodium chlorite solution with a concentration of 10% dropwise. After stirring evenly, add 0.25g of citric acid to activate it. Add 2ml of essence and 0.2g of food coloring agent in turn to the activated solution, and stir well. Pour into molds to cool.

[0045] Put the prepared sample into 0.125m 3 In the airtight test chamber, drop the formaldehyde concentration to 1.25mg / m 3 , after 40min the concentration of formaldehyde drops to 0.01mg / m 3 .

[0046] Referring to the test method in the patent document CN105145626A to detect the sustained release rate, the results show that the time for the product release rate to be greater than 150 μg / h is 39 days.

Embodiment 3

[0048]Weigh 50g of sodium stearate and heat to 155°C to melt and stir evenly. Add 7ml of high-concentration sodium chlorite solution with a concentration of 10% dropwise. After stirring evenly, add 0.2g of phosphate to activate it. Add 1ml of essence and 0.1g of food coloring agent in turn to the activated solution, and stir well. Pour into molds to cool.

[0049] Put the prepared sample into 0.125m 3 In the airtight test chamber, drop the formaldehyde concentration to 1.18mg / m 3 , after 60min the concentration of formaldehyde drops to 0.01mg / m 3 .

[0050] Referring to the test method in the patent document CN105145626A to detect the sustained release rate, the results show that the time for the product release rate to be greater than 150 μg / h is 51 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com