Preparation method of magnesium alloy grain refining agent

A grain refiner and grain refinement technology, which is applied in the field of non-ferrous metal casting, can solve the problems of limiting the application range of magnesium alloys and poor plastic processing ability of magnesium alloys at room temperature, and achieve good grain refinement effect and low cost. The effect of low, thinning effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0013] A preparation method of a magnesium alloy grain refiner, the steps are as follows:

[0014] Melt 50g of aluminum-magnesium alloy in a low-carbon steel crucible or graphite crucible using a resistance furnace. After the aluminum-magnesium alloy is melted, add 2g of magnesium carbonate powder, and after the powder is fully reacted, keep it warm at 700°C for 25 minutes and cast it into a mold. After cooling to room temperature, it is solid solution treated at 380°C for 20 hours to obtain the aluminum-containing magnesium alloy.

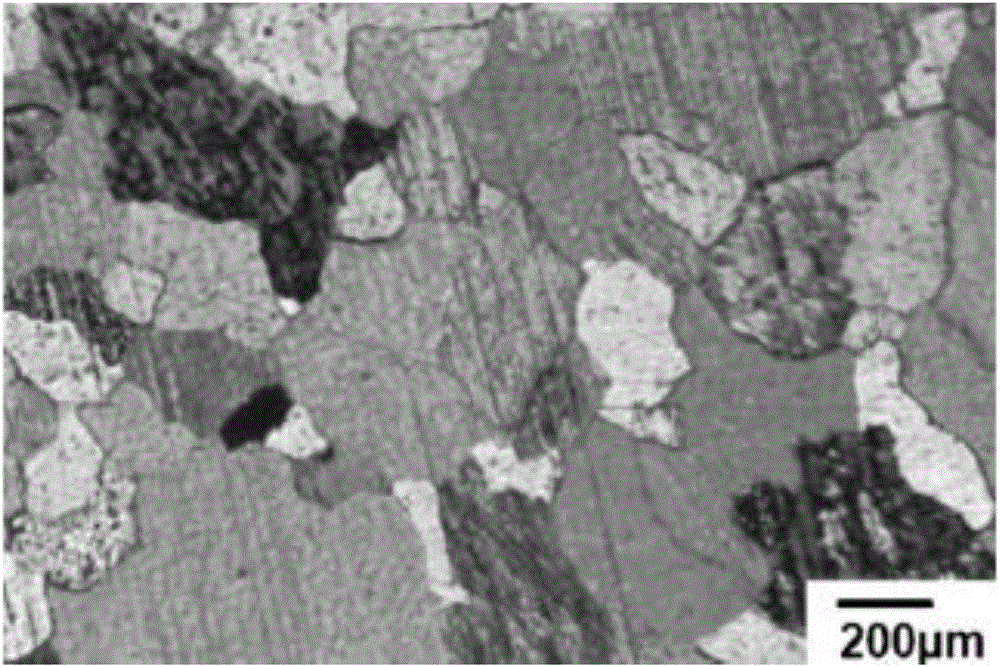

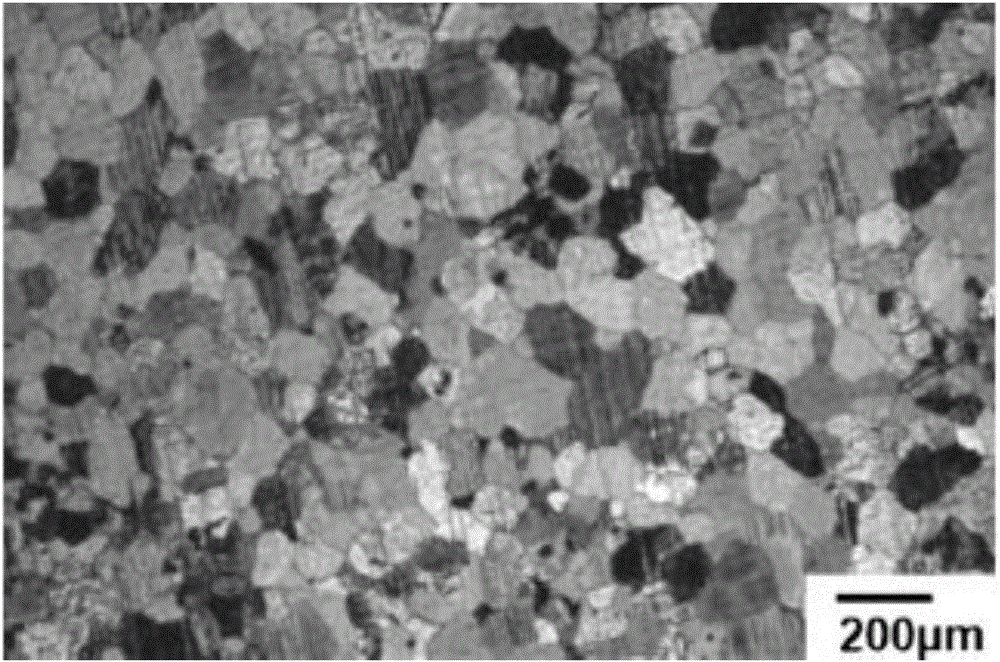

[0015] The microstructure of aluminum-magnesium alloy and aluminum-magnesium alloy with magnesium carbonate is equiaxed. After adding magnesium carbonate powder, the grain size of aluminum-magnesium alloy is refined from 370 μm to 117 μm, and the grain size is refined by 68.4%. . Wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com