Porous Hollow Fiber Membrane Spinning Device

A spinning device and fiber membrane technology, which is applied in the field of new porous hollow fiber membrane spinning device, can solve the problems of cumbersome operation, affecting product quality stability and consistency, and long maintenance time, so as to ensure uniformity and consistency , to ensure uniformity and consistency, and to reduce the difficulty of production and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention. These all belong to the protection scope of the present invention.

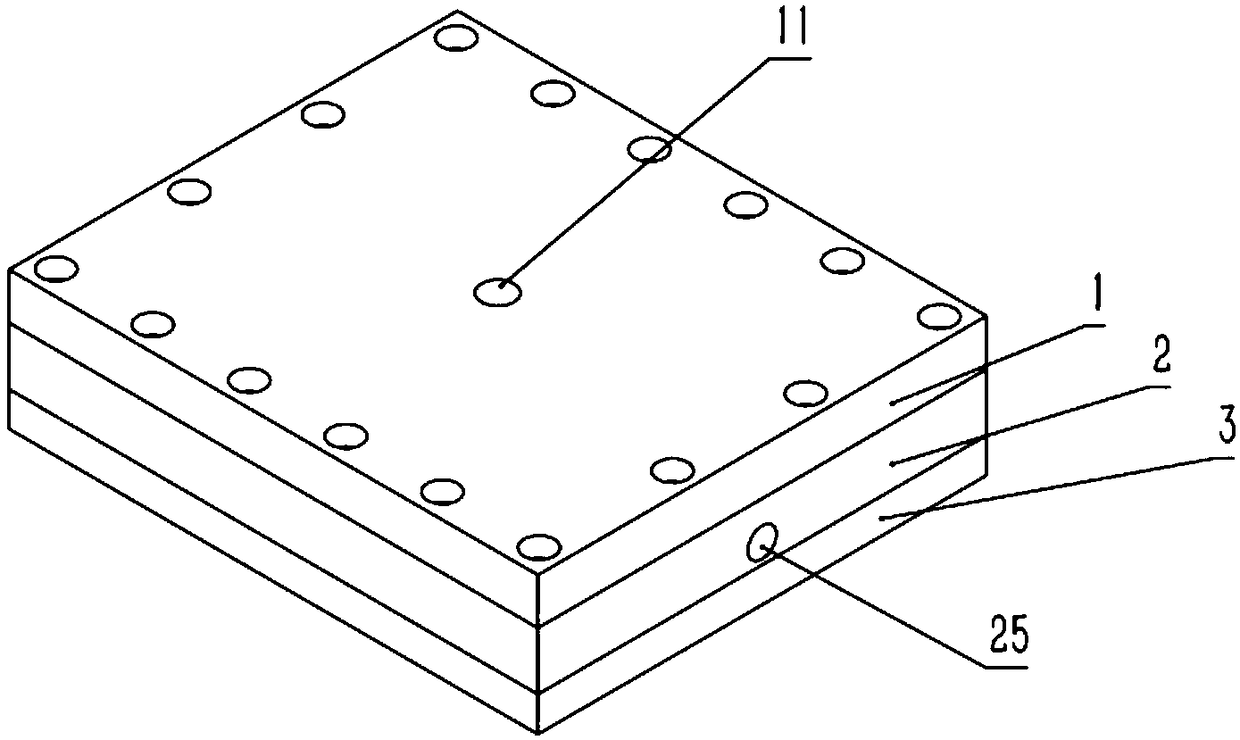

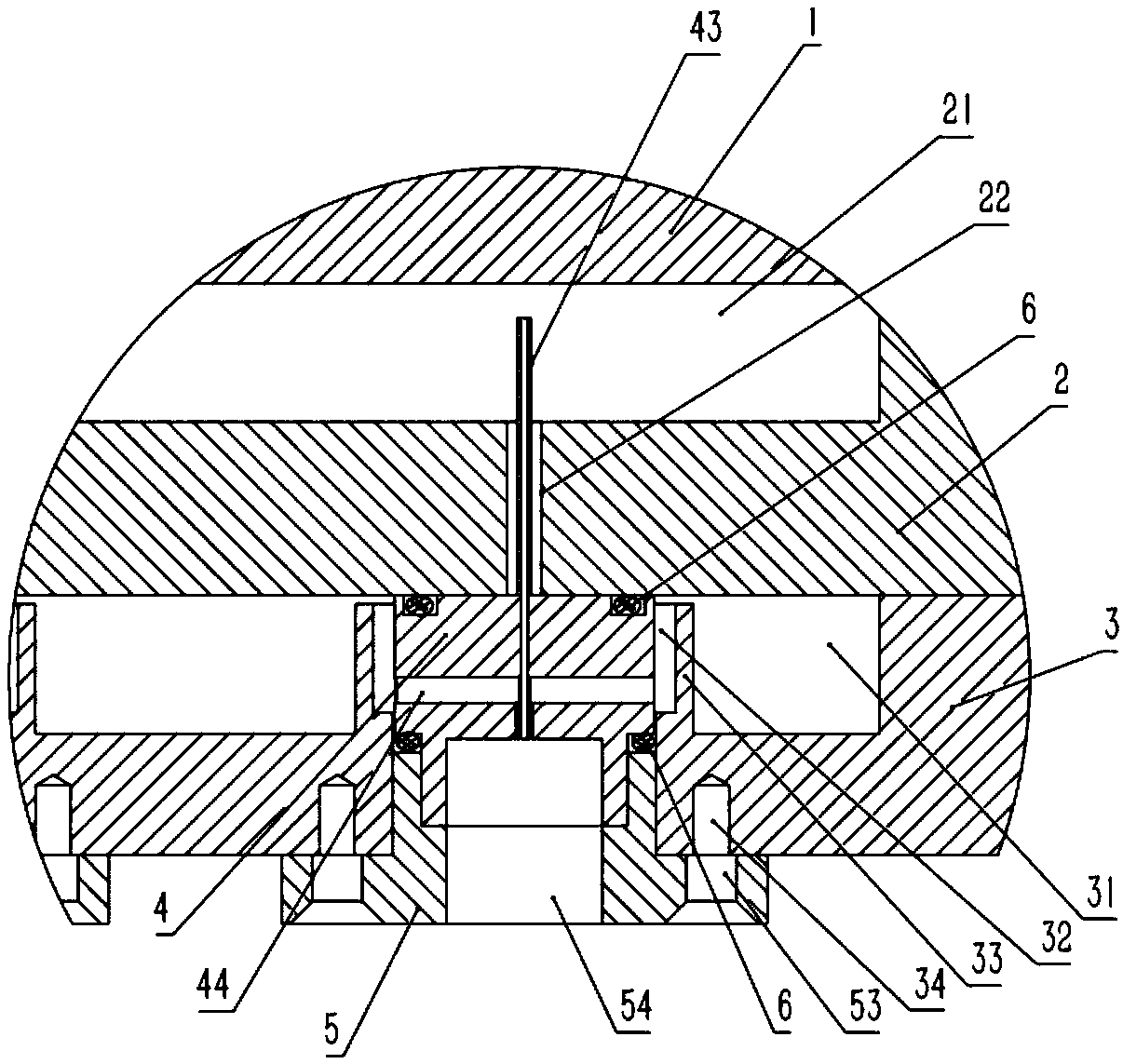

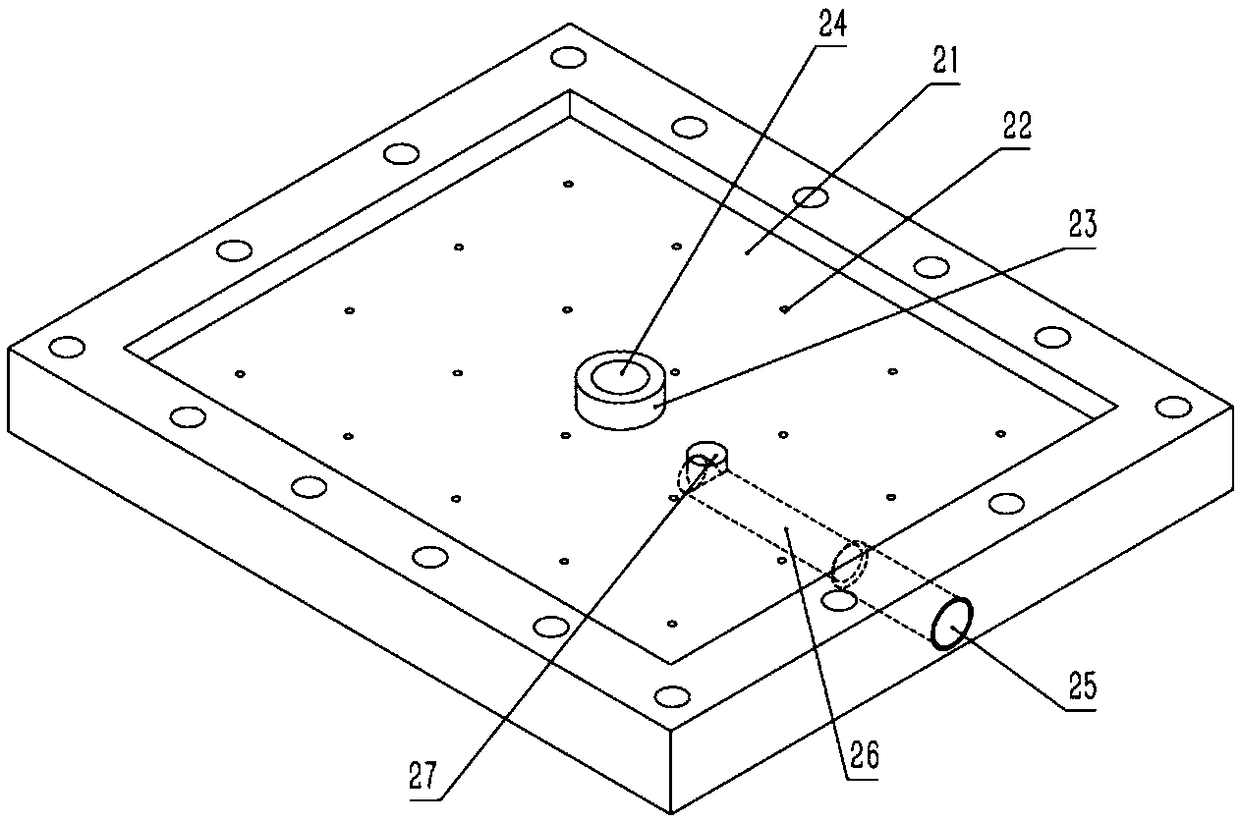

[0054] In this example, if Figure 1-7 shown. The novel porous hollow fiber membrane spinning device provided by the present invention comprises a feed plate 1, a core liquid deflector 2, a spinneret 3 and an independent spinneret 4;

[0055] Wherein, a feed liquid inlet 11 is provided at the center of the upper end surface of the feed plate 1, a core liquid chamber 21 with an open upper end is provided on the core liquid deflector 2, and a plurality of through cores are arranged at the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com