System and method for automatically and continuously detecting metal in water based on laser breakdown spectroscopy

A laser breakdown spectrum and detection system technology, which is applied in the field of automatic and continuous metal detection systems in water, can solve the problems of multiple types of reagents, high toxicity, difficulty in automation, and low detection accuracy, so as to achieve metal trace detection and avoid secondary contamination. Secondary pollution and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

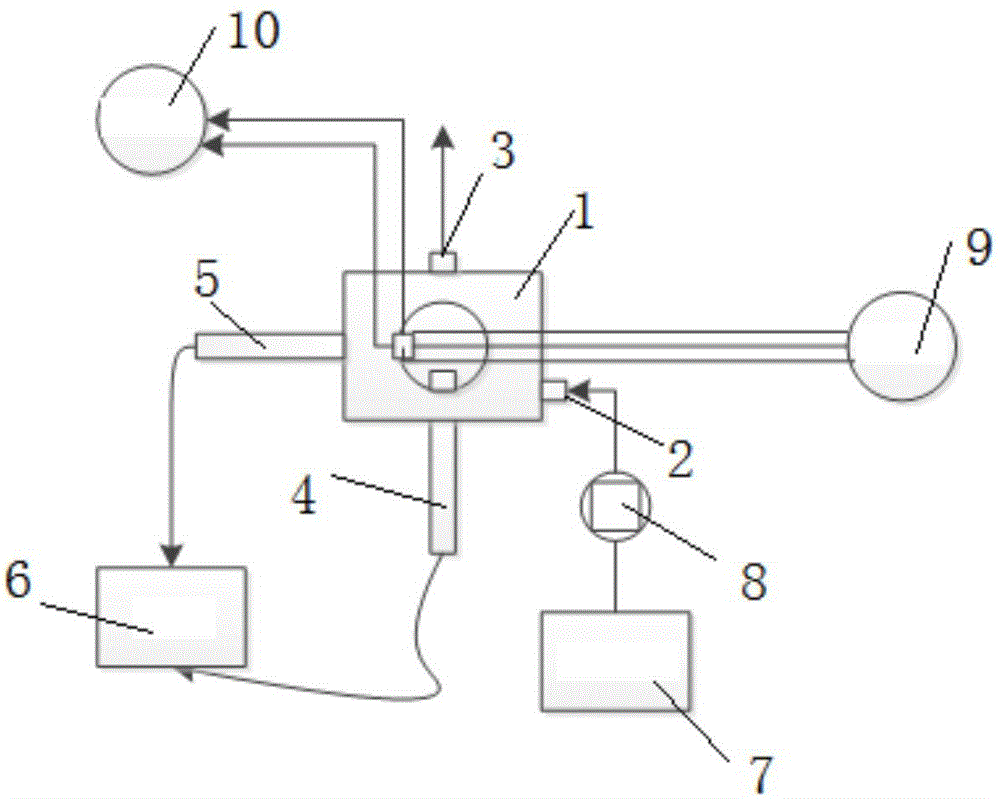

[0047] Such as figure 1As shown, the automatic continuous detection system for metals in water based on laser breakdown spectroscopy provided by the present invention includes a laser 9, a spectrometer 10, a detection pool 1, a second electrode 4, a first electrode 5 and a drying processing unit; the detection pool 1 has a sample feeding End 2 and sample outlet 3, specifically sample inlet port and sample outlet port, for water samples to enter and flow out of the detection cell 1; the second electrode 4 and the first electrode 5 are all in contact with the water sample in the detection cell 1, so that The metal in the water sample in the detection tank 1 is enriched to the first electrode 5; the drying treatment unit is arranged on the side of the detection tank 1, and the first electrode is dried after the water sample in the detection tank is discharged; the first electrode 5 Located on the optical path of the laser 9, the metal enriched on the first electrode 5 generates p...

Embodiment 2

[0063] Another aspect of the present invention also provides an automatic and continuous detection method for metals in water based on laser breakdown spectroscopy, which includes the following steps:

[0064] S1. Continuously input water samples into the detection tank 1, and continuously discharge the water samples when the detection tank 1 is full;

[0065] S2, turn on the power supply 6, and make both the first electrode 5 and the second electrode 4 contact the water sample in the detection cell 1, so that the metal in the water sample in the detection cell 1 is enriched to the first electrode 5;

[0066] S3, striking the laser light of the laser 9 on the first electrode 5, so that the enriched metal generates plasma;

[0067] S4. Receive the spectral signal of the plasma through the spectrometer 10 .

[0068] Which also includes between S2 and S3:

[0069] S20 , after a predetermined metal enrichment time, discharge the water sample in the detection cell 1 , and dry the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com