Thick-wall steel tube internal crack detection method based on surface magnetic conductivity differential measurement

A detection method and technology for internal cracks, which are used in measurement devices, material magnetic variables, material analysis by electromagnetic means, etc., can solve problems such as inability to detect small cracks, difficulty in detection, etc., and achieve rapid automatic detection, versatility and interchangeability. The effect of strong performance and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

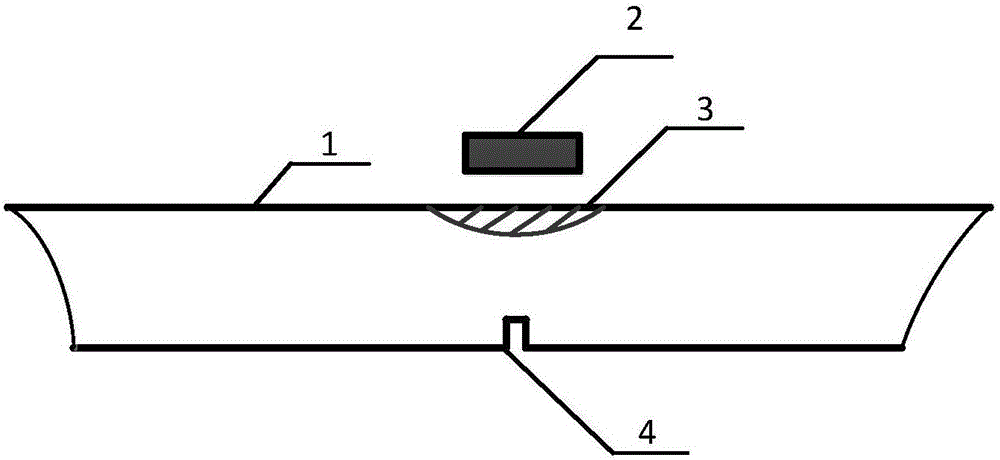

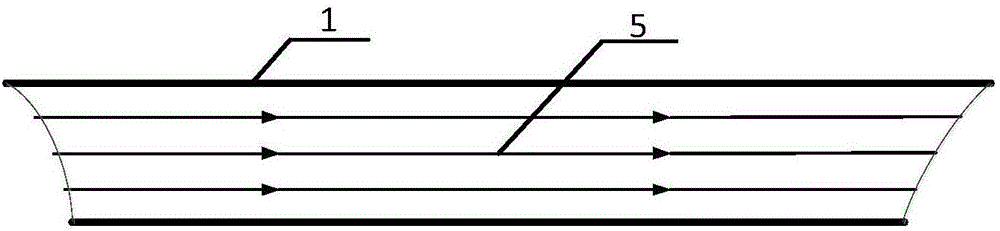

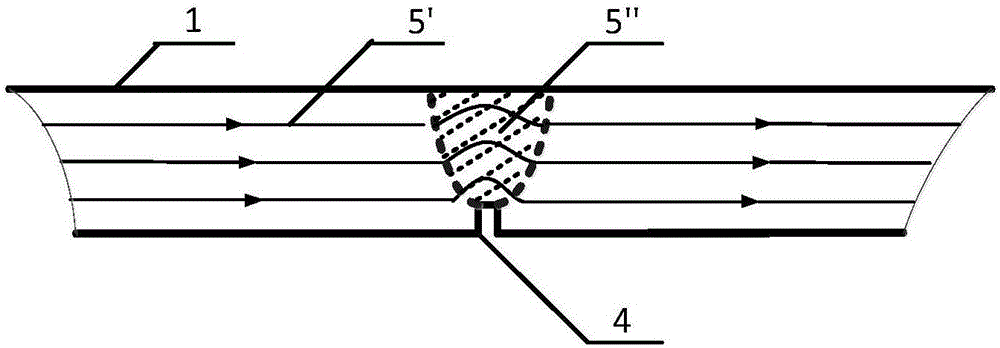

[0033] like figure 1 As shown, when the steel pipe 1 is not magnetized, its internal magnetic permeability is uniformly distributed. The eddy current detection probe 2 scans along the outer wall of the steel pipe 1, and the surface of the steel pipe 1 induces eddy currents. Due to the skin effect of the eddy currents, the eddy currents are mainly distributed in the figure 1 Area 3 shown. Even if there is an inner wall crack 4 on the inner wall of the steel pipe, the wall thickness is far greater than three times the skin depth of the eddy current. The eddy current fails to reach the crack 4 on the inner wall, so the output of the detection probe 2 does not change, that is, the crack on the inner wall of the steel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com