Interface device for micro-flow electrokinetic chromatography coupled with nano-liter electrospray ion source mass spectrometry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

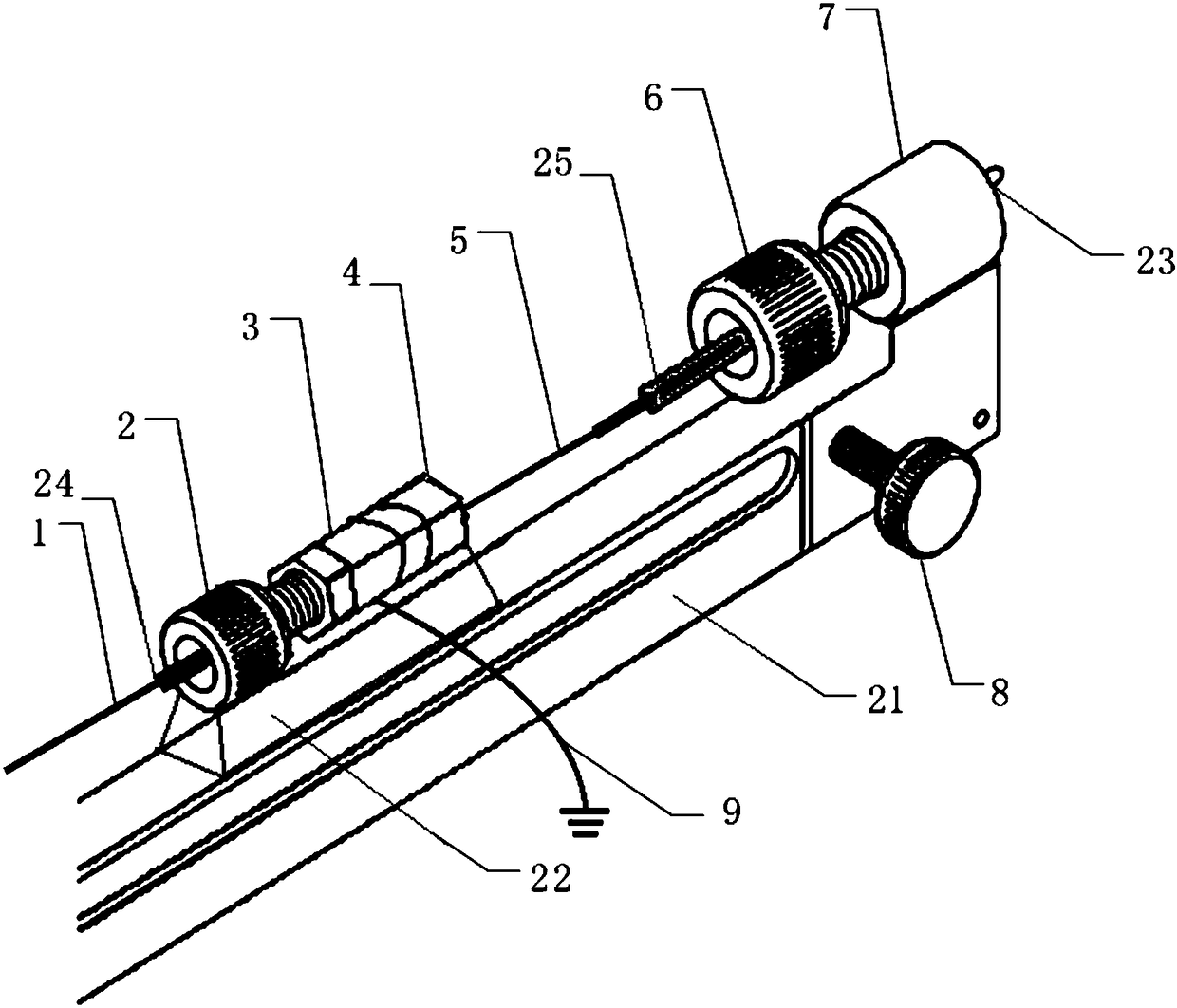

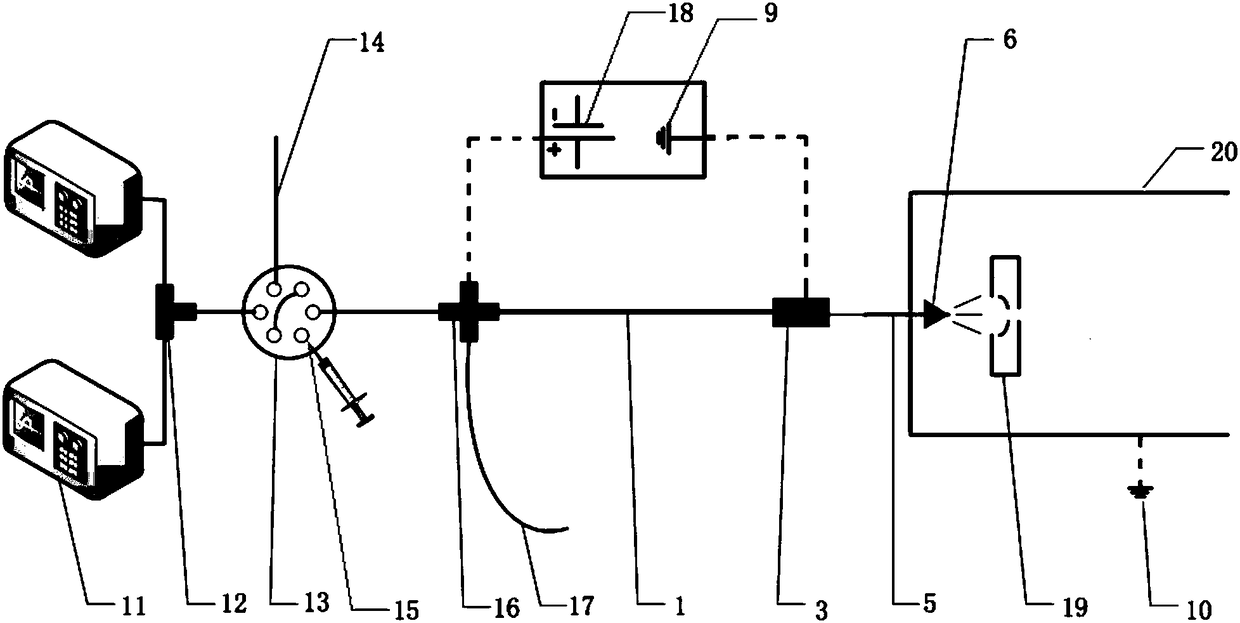

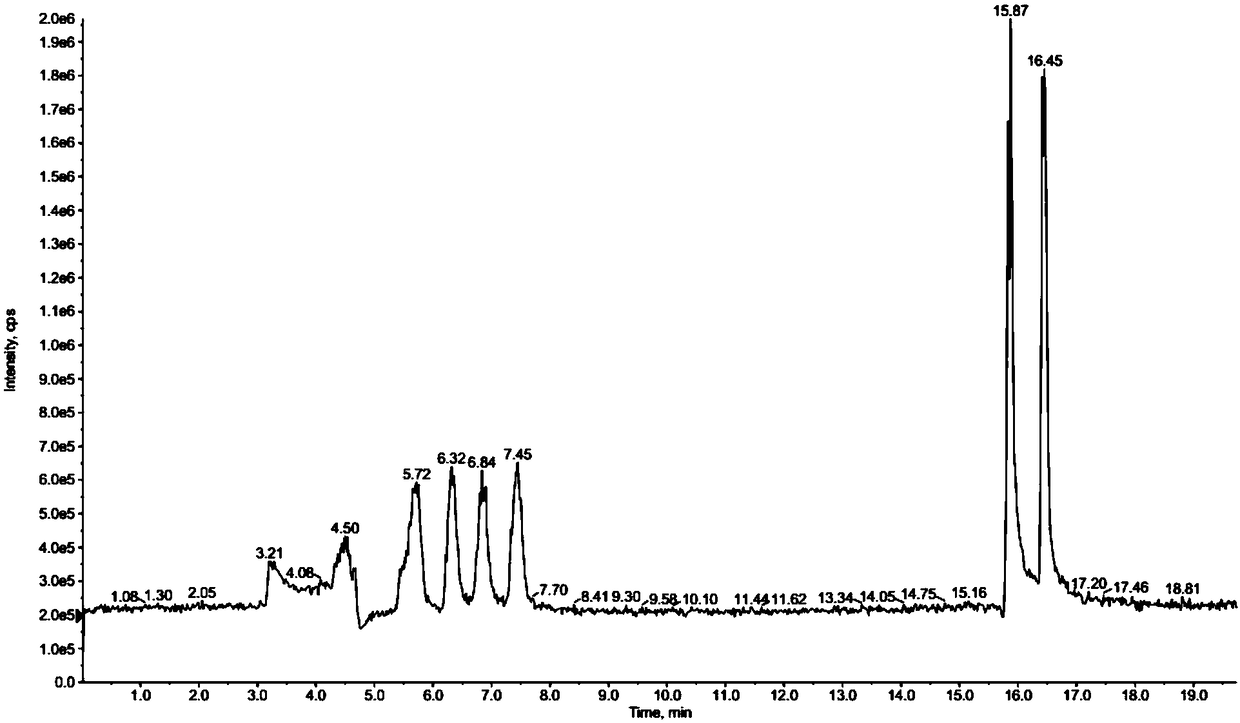

[0116] After taking samples containing 8 kinds of amino acids for pretreatment, such as Figure 1-2 As shown, the mobile phase is mixed in the mixing valve through two micro-flow pumps, and then mixed with the sample to be tested that enters the injection valve through the injection port, enters the connecting valve through the pipeline, and the capillary chromatography in the connecting valve is controlled by the power supply. A voltage is applied to the injection end of the column to increase the separation of chargeable substances in the sample, and then the sample to be tested in the mobile phase is separated through the capillary column. Among them, two microflow pumps can realize gradient elution. The excess mobile phase produced by the microflow pump after mixing in the mixing valve is discharged from the injection valve through the waste liquid pipe through the pipeline, and flows into the waste liquid pool. The excess mobile phase containing the sample to be tested i...

Embodiment 2

[0123] After taking samples containing 8 kinds of amino acids for pretreatment, such as Figure 1-2 As shown, the mobile phase is mixed in the mixing valve through two micro-flow pumps, and then mixed with the sample to be tested that enters the injection valve through the injection port, enters the connecting valve through the pipeline, and the capillary in the connecting valve is controlled by a high-voltage power supply. A voltage is applied to the injection end of the chromatographic column to increase the separation of chargeable substances in the sample, and then the sample to be tested in the mobile phase is separated through the capillary chromatographic column. Among them, two microflow pumps can realize gradient elution. The excess mobile phase produced by the microflow pump after mixing in the mixing valve is discharged from the injection valve through the waste liquid pipe through the pipeline, and flows into the waste liquid pool. The excess mobile phase containi...

Embodiment 3

[0130] After taking samples containing 8 kinds of amino acids for pretreatment, such as Figure 1-2 As shown, the mobile phase is mixed in the mixing valve through two micro-flow pumps, and then mixed with the sample to be tested that enters the injection valve through the injection port, enters the connecting valve through the pipeline, and the capillary chromatography in the connecting valve is controlled by the power supply. A voltage is applied to the injection end of the column to increase the separation of chargeable substances in the sample, and then the sample to be tested in the mobile phase is separated through the capillary column. Among them, two microflow pumps can realize gradient elution. The excess mobile phase produced by the microflow pump after mixing in the mixing valve is discharged from the injection valve through the waste liquid pipe through the pipeline, and flows into the waste liquid pool. The excess mobile phase containing the sample to be tested i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com