Two-dimensional code positioning-based intelligent warehousing mobile robot system

A technology for mobile robots and intelligent warehousing, applied in two-dimensional position/channel control, control/adjustment systems, instruments, etc., can solve problems such as high power consumption, yaw of automatic navigation vehicles, and difficult warehouse optimal paths, etc. Achieve accurate positioning and eliminate cumulative errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

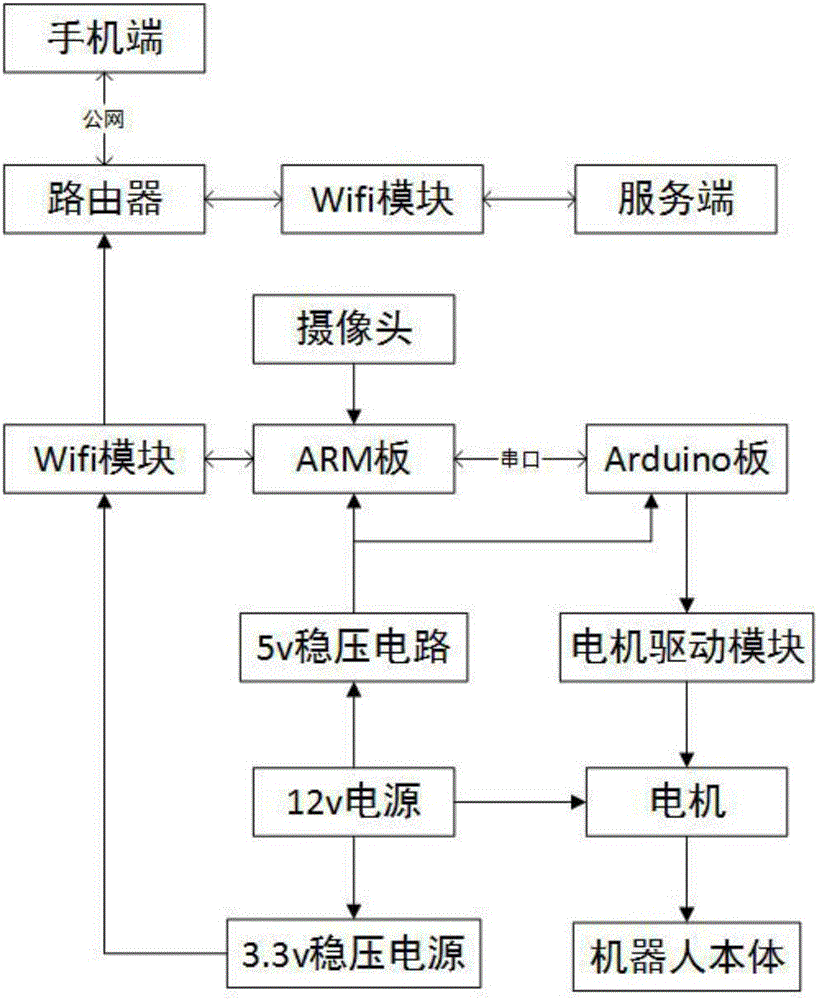

[0020] The intelligent warehousing mobile robot system of the present invention takes the central server as the center, connects the mobile phone client at the top, and connects the ARM board and the aduino board at the bottom. The system hardware framework and the communication scheme of each module are as attached figure 1 shown.

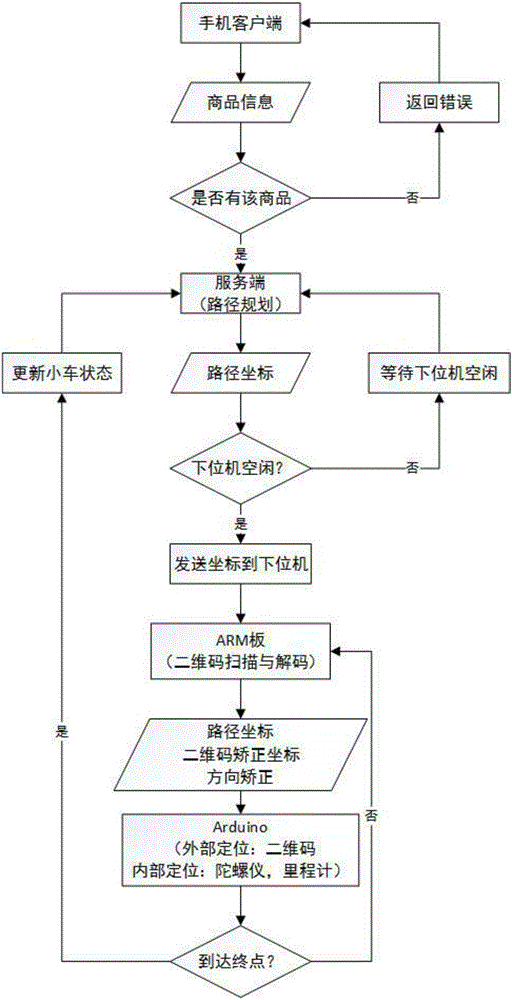

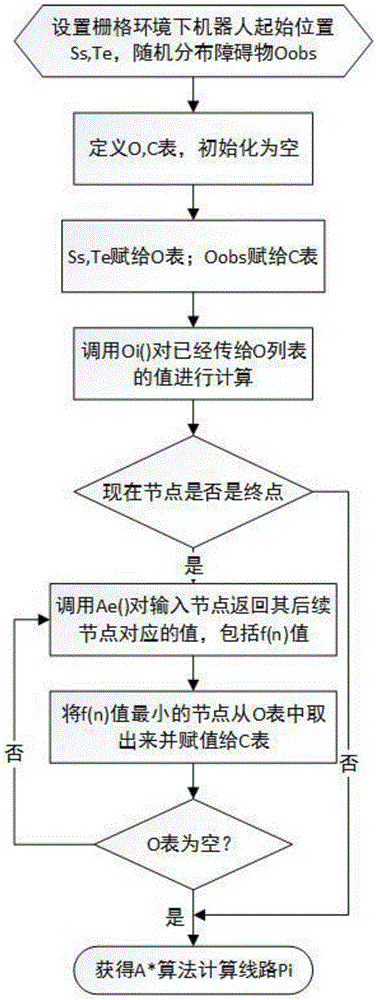

[0021] The working process of the entire hardware system platform: firstly, the APP on the mobile phone scans the QR code of the product, places an order, and sends the product information to the central server of the warehouse through the public network. The known grid map of the location and warehouse uses the A* algorithm for path planning, and calculates the optimal running path. The server sends this path to the arduino module on the robot through the WiFi module. Arduino uses its own gyroscope and mileage Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com