Method for predicting performance indexes of drafting link in carbon fiber precursor production process

A carbon fiber precursor and production process technology, applied in the field of carbon fiber intelligent production prediction, can solve problems such as lack of theoretical guidance, and achieve the effect of improving prediction accuracy, speeding up solution speed, and achieving accurate prediction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

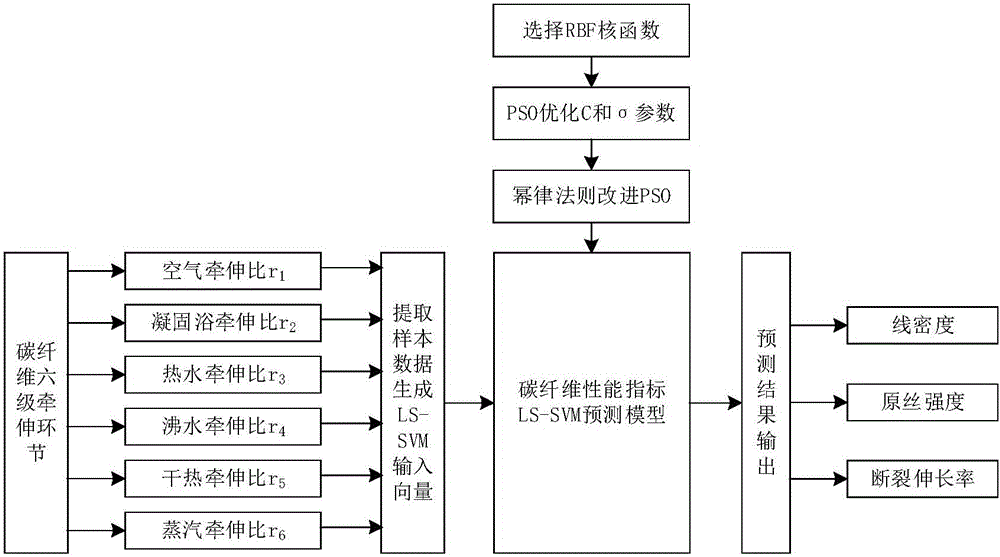

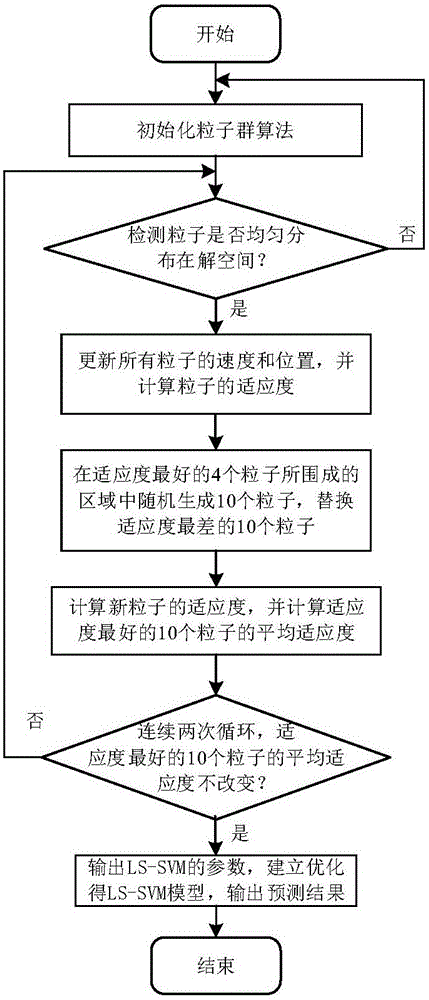

Method used

Image

Examples

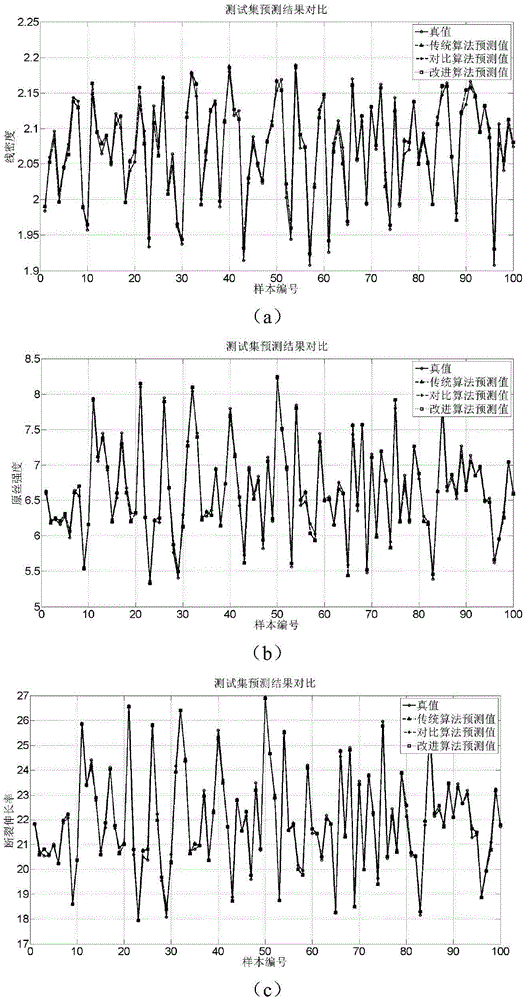

Embodiment 1

[0117] In order to verify the validity of the improved prediction method, the prediction method is tested according to 500 sets of input and output sample data. The sample data is divided into training samples and test samples according to the ratio of 8:2, that is, the training samples are 400 sets of data, and the test samples are 100 sets of data. In PSO, the number of particles selected is 20, and each particle has 2 dimensions, which respectively represent the penalty factor C and the kernel function parameter σ that need to be optimized. In this example, based on the power law law to improve the PSO optimization process, 50% of the particles are eliminated, and 10 particles are randomly generated in the area surrounded by the 20% of the particles with the best fitness as the replacement particles for the eliminated particles. The cut-off condition of the program is: the average fitness value of the function obtained by two consecutive optimizations remains unchanged. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com